Background

Since a crystal oscillator has a

temperature dependence you get better performance when the

crystal and the associated oscillator are enclosed in an

oven. A measure of how good the oven is performing is

how much the inside changes temperature when the ambient

temperature changes one degree. By using double ovens

and maximizing the gain of the temperature control loops the

level of oven performaqnce is improved.

These were used in the HP Z3815A which was a GPS disciplined

oscillator used for cell phone timing (maybe in Australia).

Major ICs

U105 44pin

Microcontroller (maybe PIC) marked E1938-80002, Rev 3719,

9729B (Fig 1 upper right)

U104, U105 16 pin

AD7243

CMOS, 12-Bit Serial DACPORT - 100k S/s (Fig 1 just to the left

of U105)

U11

AD7714

28 pin CMOS, 3V/5V, 500 µA, 24-Bit Sigma-Delta,

Signal Conditioning ADC (Fig 1 bottom center)

U200 14 pin

LMC660

CMOS Quad Operational Amplifier (Fig 1 upper left)

Versions

There were different versions:

The

Z3815A

GPS Time Frequency Reference GPSR-A VXI instrument like

this one has a D connector on the bottom with sockets.

The E1938A puck on PCB as shown above (has a D connector on

the top with pins.)

E1938-60201 is just the puck

Operation

Connector

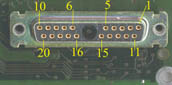

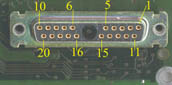

The

connector on the bottom of my unit is a special "D" type with

20 sockets and a center hole where a coax connector might be

installed (not in this one).

Tom's E1938

has the connector installed on top of the board and his has

male pins. Pin numbers are as shown in the photo on the

left.

These connectors will mate with standard DB-25 series

connectors, but the pin numbers are only the same for pins 1

to 5. Three pins are skipped between 5 and 6 and two

pins are skipped between 15 and 16.

The E1938A was sold to

at least 3 major customers and we played games with the

connector to make it compatible with them. I don't

remember exactly why that funny connector was used. Either

the connector it had to mate with had coax inserts already

for historical reasons, and the E1938A connector had to at

least have holes in it without inserts to allow mating, or

there was some other arcane reason like the connector with

inserts was a different height or something. Some versions

had the connector on the other side of the board. Whatever

the reason was, you don't need to worry about it because

no version of the E1938A ever used those coaxial

positions. I think you can put a regular connector in

there if you clip off the unused pins. I vaguely remember

shenanigans like that.

-Rick-

Top and Bottom photos annotated with function of each pad or

pin.

E1938A_Pinout_Pictorial.pdf

Theory of Operation

Theory.pdf

explains the schematic and block diagrams.

Back Side Component Locator

E1938asdrawa.pdf E1938asdrawb.pdf

Top Side Component Locator

E1938asdrawa-8.pdf

GIF format

schematics of the board and oscillator and layout drawings

as E1938gifs.zip file.

pdf format schematic of the board and oscillator & layout

drawings as

E1938pdfdocs.zip

On the computerized data printout there is an item called

Hz off freq. after warm up:

This is a measure of how well the reasonating capacitor was selected by the factory to center 10 MHz in the EFC window.

Temperature Control

The 10811 has an ANALOG oven control loop. The gain is set to

be just

below the oscillation point. This is due to the stability

limits

dictated by the oven mass and (believe it or not) the size of

integrator capacitor that can physically fit. If you want to

"soup up"

at 10811 oven, externally wire a larger capacitor in parallel

and

change the resistors to increase the gain. The 10811 designers

did the

best they could with what they had to work with, but you don't

want to

blindly copy them in new applications. BTW, do not use a

"metalized" plastic integrator capacitor. Must be "foil" type.

I am extremely happy with the PII^2D control loop on the

E1938A (I

didn't design it, only tested it). I can't imagine anything

being

better.

I would like to point out that

the

E1938A uses a PID controller and has a *transient* thermal

gain of many

1000's not to mention a static gain that has in some cases

exceeded

1,000,000 for a single oven.

(referring to another temperature control system) The block

cannot be

well insulated because of the thermal overhead of the oven

circuitry

(the heat has to escape). I explained in my 1997 FCS paper

how to

achieve the isothermal condition, which is achieved by

symmetry rather

than high amounts of insulation. The E1938A oven works quite

well if

the insulation is omitted or replaced by poor insulation,

except that

it consumes more power.

Referring to vacuum oven:

http://rfdesign.com/vlf_to_uhf/time_and_frequency/709RFDF1.pdf

At HP, in the 90's, we did a lot of brainstorming about

vacuum ovens.

This never seemed to make sense to us. If you actually

achieve high

amounts of thermal resistance, then you can't get the heat

out of the

oven. And if you don't, why bother with a vacuum. Also, a

vacuum only

helps if you do everything else you need to do to make a

true Dewar

(thermos bottle), like having mirrored surfaces, etc.

Finally, having a

vacuum means that nothing that outgasses can be used in the

oscillator.

Maybe Vectron has figured out something we didn't think of

or has

sufficiently difference constraints that a vacuum makes

sense for them.

We went through this tradeoff on the E1938A. Resistive

heaters can be

distributed. However, it is very inefficient to drive them

with

transistors, because then you waste a lot of power heating

the

transistors, which is waste heat if resistive heating is

used. Prior to

the 10544, they just put up with this. The 10544 used a

switching

regulator for up the efficiency, but it put a 1 kHz spur on

the

oscillator. The 10811 used two transistors on opposite sides

to try to

sort of distribute the heat. On the E1938A, we looked at an

array of

small surface mount transistors to have the best of both

worlds.

However, this turned out not to be manufacturable and we

settled for

resistive heaters (back to 1970!).

-Rick-

Computer Program

NGOcomm.zip

- Windows control program & 3 DLLs it needs.

Papers

A New Type of

Balanced-Bridge Controlled Oscillator, R.K. Karlquist,

HP Labs, date?, publication?

The Theory Of Zero

Gradient Crystal Ovens, R.K. Karlquist, L.S. Cutler,

E.M. Ingman, J.L. Johnson, T. Parisek, HP & HP Labs,

date?, publication?

A Low-Profile

High-Performance Crystal Oscillator For Timekeeping

Applications, R.K. Karlquist, L.S. Cutler, E.M. Ingman,

J.L. Johnson, T. Parisek, HP & HP Labs, date?,

publication?

Patents

Directly Related to the E1938

2004613

Phase Shifting Apparatus, Larned A. Meacham, assigned to Bell

Telephone Labs, filed Aug 23, 1933, issued Jun 11,1935,

323/218

; 361/299.1

2163403

Stabilized Oscillator, Larned A. Meacham, assigned to Bell

Telephone Labs, filed July 2, 1937, issued June 20,

1939.,

331/139 ; 331/140; 331/183; 331/66; 333/17.1;

333/188 - uses light bulb to stabilize a crystal oscillator.

2268872

Variable Frequency Oscillation Generator, William R. Hewlett,

assigned to H-P, , filed June 11, 1939, issued Jan 6, 1942,

331/141

; 331/183 - this is the model 200A audio oscillator that got

H-P

started. - uses light bulb to stablize a bridge audio

frequency

oscillator. The frequency is controlled by an air

variable

capacitor which would not have any effect on conventional

audio

frequency oscillators.

The E1938A project started out as a Meacham bridge

oscillator and the

number was chosen because it was the date of invention of

that

oscillator. Eventually, we realized that design wasn't going

to work

for us and we had to invent our our bridge oscillator.

The lamp thing is interesting because there is a lot of HP

folklore

that has grown up around the HP garage, the invention of the

200A

oscillator, etc, and it seems that Bill Hewlett has gotten

credit for

the lamp stabilization idea. Possibly, he independently

invented it,

since he filed 6 months after Meacham did, but long before

the Meacham

patent was granted. Hewlett also copied or reinvented the

idea of a

bridge oscillator. His real contribution was to harness

Meacham's

previous technology to enable him to eliminate the inductor

from the

oscillator, which allowed him to raise the impedance level

high enough

to allow air variable capacitors to be used. It was a great

design,

whoever invented it.

(According to tradition, the model number 200 was used

instead of 100

to give the impression that this wasn't the first HP

product).

The original Hewlett patent is on display at Agilent

headquarters where

I work. I was kind of surprised that HP ("HP Invent") let

Agilent have

it. I am also pleased that in the HP Archives museum, on the

first

shelf, in the center, is a *working* 5071A. There is also,

of course, a

200A oscillator on display.

The above are my own opinions and don't represent Agilent or

HP.

Rick Karlquist

2275452

Stablized Vacuum Tube Oscillator, Larned A. Meacham, assigned

to Bell

Telephone Labs, filed June 24, 1935, issued March 10, 194

5708394

Bridge-Stabilized Oscillator Circuit and Method, R.K.

Karlquist, Jan 13, 1998, 331/1R ; 331/116R; 331/139; 331/158;

331/177V; 331/183

5729181

High Thermal Gain Oven With Reduced Probability Of Temperature

Gradient Formation For the Operation Of a Thermally Stable

Oscillator,Cutler; Leonard S. (Los Altos, CA), Karlquist;

Richard K. (Cupertino, CA), Collin; James R. (Palo Alto, CA),

Johnson; James L. (Morgan Hill, CA), Parisek; Theodore (San

Jose, CA), Giffard; Robin P. (Los Altos, CA) ,March 17,

1998, 331/69 ; 310/315; 310/343; 331/158

Calls:

Called by:

| 7,113,051 |

Frequency

characterization of quartz crystals |

| 7,102,220 |

Multiple

cavity/compartment package |

| 6,784,756 |

On-board

processor compensated oven controlled crystal

oscillator |

| 6,606,009 |

Self-compensating

ovenized clock adapted for wellbore applications |

| 6,362,700 |

Temperature

controlled compensated oscillator |

| 6,208,213 |

Thermostatically

controlled crystal oscillator |

| 6,166,608 |

Thermo-electric

cooled oven controlled crystal oscillator |

| 6,127,661 |

Dynamic

thermal control for ovenized oscillators |

| 6,060,692 |

Low

power compact heater for piezoelectric device |

| 6,049,256 |

Low

profile ovenized oscillator packing having a high

thermal conductivity substrate |

| 5,919,383 |

Package

for a temperature-sensitive optical component with

inner and outer containers and resistive element

therein |

| 5,917,272 |

Oven-heated

crystal resonator and oscillator assembly |

Links

Back to Brooke's

Time & Frequency,

Electronic Crystal,

Crystal Unit Equivalent Circuit,

Crystal Temperature compensation Patents,

home page

[an error occurred while processing this directive] page created 26 Aug

2007.

The

connector on the bottom of my unit is a special "D" type with

20 sockets and a center hole where a coax connector might be

installed (not in this one). Tom's E1938

has the connector installed on top of the board and his has

male pins. Pin numbers are as shown in the photo on the

left.

The

connector on the bottom of my unit is a special "D" type with

20 sockets and a center hole where a coax connector might be

installed (not in this one). Tom's E1938

has the connector installed on top of the board and his has

male pins. Pin numbers are as shown in the photo on the

left.