Miscellaneous Old Stuff

© Brooke Clarke 2012 - 2020Atomizers

Sen-Sen

Apple Peelers

Photos

Patents

Related

Links

Background

There was some items I wanted on

eBay but they were in a lot of other stuff that's also

instering, so this page will be for stuff that doesn't fit an

existing page.

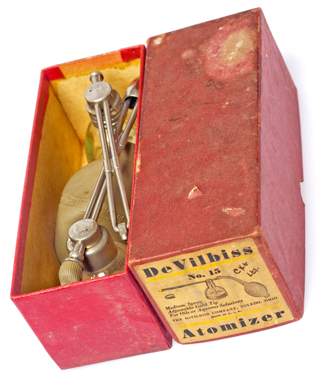

Atomizers

I think used for perfume.

De Vilbiss made paint spray guns and related air compressors

to drive them. They used the same principle as these

atomizers.

|

No.

15 DeVilbiss Health Care The top atomizer has no markings. The bottom one is marked No. 15 and the bulb De Vilbiss No. 1. |

|

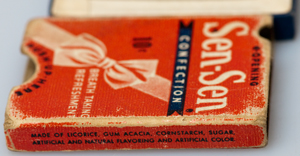

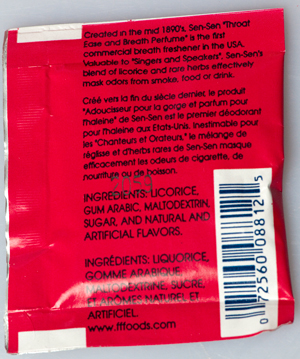

Sen-Sen

Since 1890 this breath freshner

has been on the market. Made by The

Smith Brothers who also make cough drops.

|

Licorice, Gum Acacia, Cornstarch, Sugar, Artificial and Natural Flavoring and Artificial Color. |

|

|

Licorice, Gum Arabic, Maltodextrin, Sugar, and Natural and Artificial Flavors. |

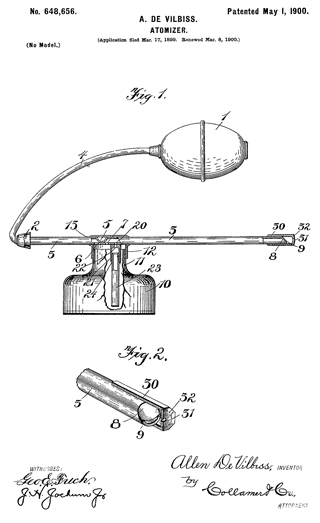

Patents

Atomizers

The vast majority of the patents

filed by A. De Vilbiss were related to Toledo scales.

935094 Closure for Fluid Receptacles, A. De Vilbiss,Sep 28 1909, 215/309 - avoids ground joints and gaskets.

1887949 Medicinal Spray, J.B. Schmitt (De Vilbiss Co), Nov 15 1932, 239/135; 239/338; 239/370 - includes a electrical vibrator pump

2686696 Atomizer, W.P. Carr (De Vilbiss Co), Aug 17 1954, 239/272; 239/345; 239/362 -

2847248 Nebulizer, J.B. Schmitt & W.H Corgett (De Vilbiss Co), Aug 12 1958, 239/338; D24/110 -

Nebulizers

735723 Nebulizer, T. De Vilbiss, Aug 11 1903, 239/338; 239/424; 239/505 - for inhaling a mist1031250 Process for Demonstrating Perfumes or the Like, T. De Vilbiss,July 2 1912, 512/3 - adds glycerin so the cloud from the nebulizer can be seen

1266228 Combined Aspirating and Vaporizing Instrument, T. De Vilbiss (De Vilbiss Manf Co),May 14 1918, 128/200.14 -

Cough Drops

407696 Apparatus for Casting mEtals Under Pressure, J.J.C. Smith & C. Grasser (Smith Brothers Mfg Co), Jul 23, 1889, 164/314 -426375 Method of and Apparatus for Making Dies, C. Grasser, Apr 22, 1890, 164/120; 76/107.1 -

3035972 Preparation and Method for Obtaining Relief from Coughing, H.J. Spoor & R.J. Weir (Smith Brothers Inc), May 22 1962

Apple Peelers

My grandmother had one that clamped to the kitchen table and I used it to peel and core many apples for use in a pie.

Johnny Appleseed (Wiki) "...he was bringing the gift of alcohol to the frontier." The water in many places was not fit to drink. But hard cider was safe. That lead to Prohibition (Wiki).

Found one made by Reading Hardware with a number of patent dates.

There are a number of functions and the more of them a machine does the more time it can save.

All the machines I've seen require a human to push the apple onto a fork and in a way that the axis of the core goes through the core.

Peeling (paring): removes the skin. Not all machines do this well on every apple. It a piece of skin gets stuck under the cutter blade it will stop working so needs to be cleared by the operator.

Slicing: A blade typically makes a spiral single long slice. If you need visually appealing slices a single manual cut will provide them. On some machines this blade can easily be removed if slicing is not wanted.

Coring: Removes the core as a cylinder.

Extraction: a shoe kicks the apple off the fork. If a machine has then feature there should be a way to have a container below to catch the finished apple.

Speed of Operation: Depends a lot on how well the machine works. If it fails often then the handwork required to fix the mistakes lowers the throughput.

Photos

Fig 1

Fig 2

Fig 3

Fig 4

Fig 4

Fig 5

Fig 6

The ratchet arr is shown lifted and you

can see Patent Pend.

Patents

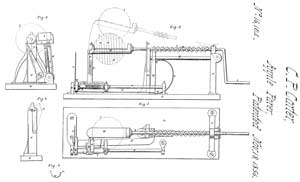

16104 Apple Parer, Nov 18, 1856, 99/598; 99/543 -

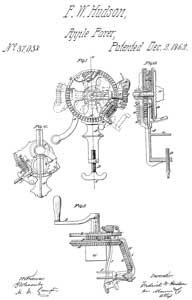

37038 Apple Parer, F. W. Hudson, Dec 2, 1862, 99/595; 99/599 -

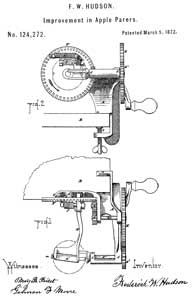

124272 Improvement in Apple Parers, F.W. Hudson, March 5, 1872, 99/599 82/128 -

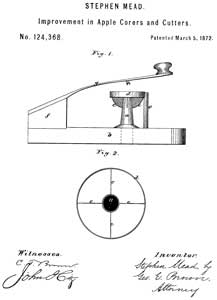

124368 Improvement in Apple Corers and Cutters, Stephen Mead, March 5, 1872, 99/545 116/DIG.12 -

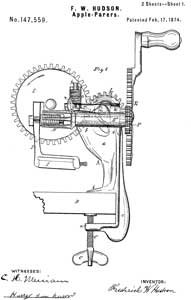

147559 Apple-Parers, F.W. Hudson, Feb 17, 1874, 99/599 -

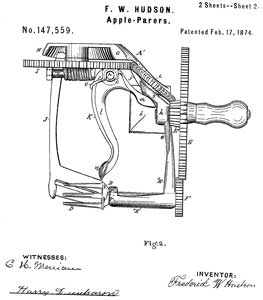

173942 Apple-Parer, W.M. Griscom, Feb 22, 1876, 99/594 -

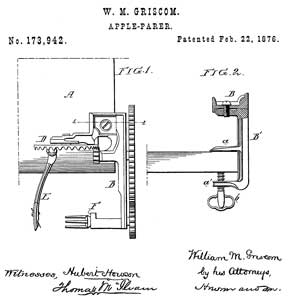

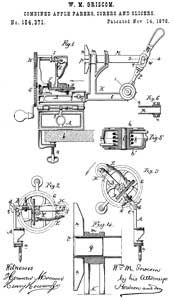

184371 Combined apple Parers, Coreres and Slicers, W.M. Griscom, Nov 14, 1876, 99/543 99/599 -

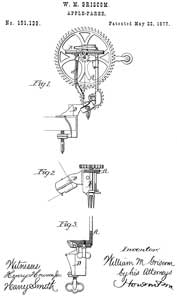

191138 Apple Parer, W.M. Griscom, (Reading Hardware) May 22, 1877

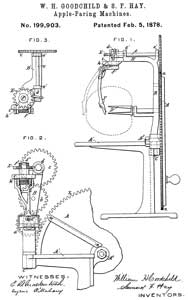

199903 Apple-Paring Machines, W.H. Goodchild & S.F. Hay, Feb 5, 1878, 99/592 99/599 -

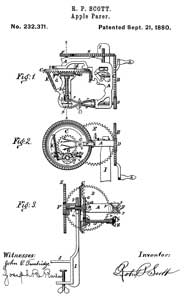

232371 Apple Slicer, R.P. Scott, (later: Sinclair Scott), 1880-09-21, 99/593; 99/599 -

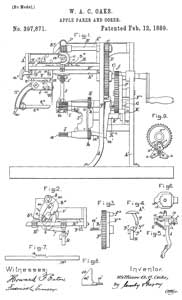

397871 Apple Parer and Corer, W.A.C. Oaks, Goodell Co, 1889-02-12, 99/597; 99/599; 99/543; 188/83 -

YouTube: Best Apple peeler slicer Goodell Bonanza -

YouTube:3 Vintage Apple Peelers/Slicer/Corer -

Related

Faradic

Instruments (Quack Medical)

Sperti Sun Lamps

Links

PRC68 Home

Page, Alphabetical List of web

pages, Products for Sale,

Sensors

Page created 7 June 2012