Drill Press

© Brooke Clarke 2007

Background

Model Numbers

About the Drill Press

5C Collet Idea

T Slots, Bolts & Nuts

Combined Drill & Countersink Set

Economy Model Indexing Spin Jig

Things that did Not Work

Recommendation

Brooke's Metal Working pages

Links

Background

For some time I've had the Harbor

Freight 44506

Five

Speed Drill Press in my garage and it gets a fair amount of

use doing things like:

- drilling holes in a 2x4

- enlarging holes in printed circuit boards that the maker did

not fully drill

- drilling holes in jewlery

- drilling holes in sheet metal

- used as a lathe by turning on it's side and manually filing

or Dremel tooling bolts into eyelet tools

- others I'm not remembering

- making a countersink deeper (bit shown in photo above)

It would be nice to have a lathe either a full size one like shown

on my

lathe web page, or one of the

smaller ones.

One of the key operations for the lathe would be to drill and tap

a

hole along the centerline of the work piece. For example to

make

a spacer like used on the

257477BA

battery adapter. Or a new battery adapter where the spacer

is

very important so prototypes are needed. Or a new product

that

has the shape of a cylindrical battery with contacts on the

end.

Then it occurred to me that my existing drill press could drill

and tap

the holes. That's how this web page got started 21 Nov.

2007.

Model Numbers

The Harbor Freight Bench Top Drill

Presses are:

|

|

|

|

|

HF

|

44506

|

38119 |

44836 |

38142 |

Enco

|

|

125-1072 |

|

308-0056

|

Grizzley

|

|

G7942

|

|

G0485

|

Speeds

|

5

|

5

|

12

|

16

|

Swing

|

8"

|

8"

|

10"

|

13

7/8"

|

Quill

|

2"

|

2"

|

2 3/8"

|

3

1/8"

|

Morse

Taper

|

JT33

|

JT33

|

MT2

|

MT2

|

HP

|

1/3 |

1/3

|

1/2

|

3/4

|

Table

|

6

5/16" x 6 1/2" |

6

5/16" x 6 1/2"

|

7

7/16'' x 73/4'' |

11

/2'' dia |

$ 2007

|

discontinued

|

70 -90

|

110

|

195 -

240

|

It may be that the either of the two larger drill presses could be

retrofitted with an end mill holder such as item

45046

(3/8") or

38142

(1/2"). The ball bearings in a drill press are not designed

for

loads at right angles to the spindle axis. That makes for

two

possible problems, a lot of slop (TIR) on the spindle and if heavy

cuts

were made destruction of the bearings.

An end mill should NOT be used in a chuck because the chuck can

not

grip well enough to prevent the bit or chuck with bit coming loose

from

the machine.

After Googling for a 10" drill press many were found, but they all

seemed to have JT33 or non specified spindle tapers. There

are a

number of them sold for wood working and one of those has a quill

lock.

About the Drill Press

This is a bench top drill press with

a

chuck that can hold a 1/2" drill. The cost is about the same

or

lower than a hand held 1/2" drill and you have the advantages of a

drill press. It can easily be laid over on it's side and so

can

be used as a simple lathe with hand held tooling.

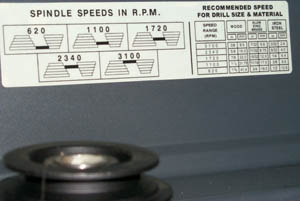

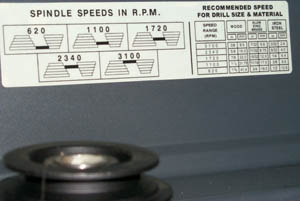

The motor is an AC type rated at 1/3 HP. There are 5 step

pulleys

on both the motor and spindle shafts allowing for 5 speeds of 620,

1100, 1720, 2340 or 3100 RPM. The motor is rated at 1750 RPM

so

there may not be a 1:1 pulley combination. Note with a

pulley

system the motor runs with it's full power potential and the

torque is

traded for speed. One of the dangers of this or any

drill

press is that the drill bit may bind and grab the material.

When

this happens the drill does not stop but instead has the tendency

of

spinning everything and if you hands are holding on they you may

suffer

some pain.

I have the speed set to 620 RPM and it seems to do fine on

everything.

The three levers that are the handles for lowering the quill

tended to

unscrew and even fall on the bench. The chuck key handle

tended

to become loose. Both of these were fixed with a drop of

Loctite

222MS thread locker.

5C Collet Idea

The key to drilling cylindrical

parts is to use a collet to hold them. The "5C"

collets are very common and considerably lower in cost than any of

the

others. So a simple 5C collet holder mounted to the drill

press

should work. It happens that Enco has a 5C set on sale and

when

you buy some more related stuff and your order goes over $ 200 the

shipping is free. So yesterday (20 Nov 2007) I placed an on

line

order and this morning (21 Nov) UPS delivered the first box

containing the

235-0000

5C Collet Set. . . Oh No another

Enco

Packing Problem.

This box contained the four items that make up the set.

|

235-6080

5C Vert/Hor Collet Fixture - The handle of this punched

the hold in the shipping box.

The advantage of this 5C collet holder is that the height

is a fraction of an inch more than the

length of a 5C collet. Since the drill press only

has 2" of quill travel and not much room between

the chuck and table this is important. The Enco 2007

catalog package photo on page 400 shows

the 235-6085 5C Vert/Hor Collet Fixture but the

table listing part numbers shows the 235-6080

and that's what I received.

The more expensive and physically higher 235-6085

loads the collets by removing the nut with lever from the

top.

This 235-6080 5C Vert/Hor Collet Fixture has the collet

inserted from the top but then the loose tommy

bar is needed to tighten the nut that's on the

bottom. If the fixture is not bolted down you can

use your

finger to tighten the bottom nut.

When the lever is pulled forward it cams a sleeve inside

the fixture pulling the bottom end of the collet

down causing it to close. The lever may get lost

since it has no home.

May be made by Zhengzhou

Machinery Co., Ltd.

2 Apr 2008 - this is getting more use than I

expected. It can

hold round stock either axis vertical (in the photo

orientation, or

axis horizontal, thus allowing drilling round stock

easily)

|

|

The Enco 5C Collet set 230-4017

is supposed to have all the sizes between 1/16" and 1

1/16" for a total of

17 collets, but this set also has the 1 1/8" collet for a

total of 18 pieces. The box would hold 20 collets.

The 15/16" collet is installed in the fixture in the above

photo. They are marked "5C" and the size on the end

making it easy to tell which one is installed.

|

|

5C Collet

The face (bottom in photo at left) has three 1/16" slots

that run back about 2 1/4" and are what allows the

collet to grip the rod. There is a 1/8" wide slot

about 0.065" deep running from the rear of the collet

about 1.9".

Whatever holds the collet will have a pin riding in this

slot that keeps the collet from spinning.

The external thread is used to trap the collet to allow

the nose taper to force the jaws closed.

The internal thread allows accessory item, like a stop, to

be installed inside the collet.

The body OD near the threads is 1 1/4" and the clear ID is

around 1". That puts a limit on the bar stock that

can be fed through the collet. But is NOT a limit on

how large an item can be held on the front.

The largest collet in the set above is 1 1/8".

There are 5C collets that are a few inches across.

|

|

235-7050

5-Piece 5C Collet Block set

contains a square and a hexagonal collet block, a couple

of nuts and a locking handle. The tapered end is at

the top of the blocks in the photo and at the bottom front

you can see the head of the locating pin which aligns

with the slot on the 5C collet to keep it from

turning. You would use either the nut or the cam

lever to tighten

the collet.

I'm not yet sure if these will work for me with the Drill

Press. Typically a part would be held in the collet

which in turn would be put into a vise. By rotating

the block you could make four or 6 cuts symmetrically.

I do have a small circular saw and an arbot to hold it on

order.

The idea is to use the drill press to cut off the rod

stock.

|

|

239-9030

Collet Rack is about 9" x 12" and holds 30 collets.

Some assembly required.

One of the 5-0.8x10 mm screws has bad thread and no

spares.

I think Enco has sent a full box of these screws, since it

was easier

for them. If you need any you can have a few for the

postage

& envelope cost. Just ask.

|

T Slots, Bolts & Nuts

The "T" slot patent 359369 by

Fredric W. Taylor was issued Mar 15, 1887 current class # 409/219

;

33/567; 33/568 prior to then the table had a smooth surface and

long

clamps were used. The old plain tables would get a arch

after use

because the clamping forces were acting over a long distance and

the

repeated stress of the cutting tool would warp the table.

The 8" drill press table and base have slots designed to accept

1/2"

"T" nuts or bolts. The "T" series parts come in a number of

sizes. The 1/2" "T" nuts or bolts use a 3/8-16 threaded bolt

or

nut. There is typically no information about this on the web

pages that are selling the drill press or the accessories for

them. I discovered this by making drawings of the various

parts. "T" fittings are on order to install the 5C collet

holder

and should be here in Nov 2007.

Here is an assortment

of components specifically for 1/2" T slot use.

On the left is a Flanged Nut (

407-5024)

with 3/8-16 thread. The flange is 0.830" dia.

In the center is a 1/2" T bolt.(

407-3010)

with 3/8-16 thread and is 1.5" long.

On the right is a 1/2" T nut (

407-2500),

unfinished Rockwell 80 washer (

891-5671)

and a 3/8-16x1.5" Grade 5 cap screw (

325-3738).

I got a number of each of these in the hope they will come in

handy not just for the first setup, but future setups.

|

|

Drill

Press to 5C Collet holder

T-Nut & Bolt

|

Drill

Press to 5C Collet holder

Bolt & Nut

|

There are a couple of problems. The T-Nuts are not tapped

through, but stop a thread or two short. I think that's done

so

that you will not run a bolt into the T-slot in a mill table or

other

T-slot that has a solid bottom. This means that the bolt

length

needs to be within a few turns of the correct length, or you add

an

extra washer or two.

The other problem is that the 0.7" slot in the 5C collet holder is

almost as wide and the OD of the heavy duty washer or the flange

on the

grade 5 nut. That makes is difficult to install since one

side of

the washer tends to fall into the slot. Using washers with

an

O.D. of 0.978" is better but still not a clean solution.

I've

seen rectangular metal plates with a center hold used in this

application, but they don't seem to be a stock part at Enco.

Making the rectangular plate would be a solution. Another

would

be to tap the T-block all the way through, or maybe drill a

clearance

hole in a couple of T-blocks. That way a T-block could be

used

upside down on top of the 5C with a bolt going into the T-block

under

the drill press table.

When working with small drill bits, like a tap drill for 2-56 or

6-32

threads like was being done prior to taking the above photos,

there's

no need to bolt down the collet holder. In this case I was

working Delrin and using small tools that would snap before they

could

move the collet holder. Same's true when the 4" vise (see

below)

is used. But when a larger diameter tool is used that has

any

chance of jamming then clamping is required. The instruction

booklets for the drill presses show a 2x4 being drilled where it

has

been rotated clockwise about the drill center line until it

touches the column. That way if the bit jams there's no room

for

the 2x4 to move.

Combined Drill & Countersink Set

Used these to deepen

the countersink in a

battery adapter

where the first design used 0.060" thick aluminum but the latest

version used 0.050" thick aluminum and now the 4-40 flat head

screw

bottomed on the

PEM insert

rather than seating on the aluminum. So the PEM inserts were

modified by using the countersink.

Flat head screws (

fasteners) are

available with different angles. The 82 degree type is what

you

get if the angle is not specified in the U.S. but in the U.K. it's

90

degrees. There is also a 120 deg version. Enco

has a

catalog page

Introduction

to Spotting Drills & Countersinks.

The meaning of the numbers is a standard.

No.

|

Body

dia

|

Drill

dia

|

Drill

Len

|

1

|

1/8

|

3/64

|

1/16

|

2

|

3/16

|

5/64

|

5/64

|

3

|

1/4

|

7/64

|

5/32

|

4

|

5/16

|

1/8

|

1/8

|

5

|

7/16

|

3/16

|

3/16

|

This is Harbor Freight set

42279,

HSS made in India.

A more common use is to start start the hole for another

drill.

These are very stiff unlike drill bits that tend to wander.

Another use is making the countersink for a lathe center.

The

drill part extends the point so the center will be seating on the

cone

and not the point. For a dead center the added volume of the

drill will make a place for oil. But for use on a lathe a

different angle is needed to match the dead or live center.

These are very handy for many drilling operations because they are

much

much stiffer than ordinary drills and so go where they are aimed.

Economy Model Indexing Spin Jig

Enco

235-6011.

Manfacturers model

PF70-5C.

My hope is that a part held in the collet can be machined by hand

rotating it while a tool that's powered (drill press, moto tool,

Mini

Cutoff Saw) does the cutting.

|

|

Index

plate numbered in 10 degree steps and lined at 5 degrees.

Vernier holes for 0 to 9 allows 1 degree steps.

Aluminum knob locks spindle.

Black sleeve traps spindle left to right.

|

Crank

is connected to hollow tube that threads onto collet.

With aluminum knob tight crank open or closed collet.

With aluminum knob loose and indexing pin out crank

turns part in collet.

|

The Enco description says that the spindle travels 2 1/16" for

flute

grinding. But as soon as the index wheel moves away from the

body

and index pin the collet is no longer indexed and is free to turn,

so

it's not clear what keeps the spindle from turning.

A 3 mm hex key is needed to loosen the sleeve to allow the side to

side motion.

The base does not have slots or holes for hold down so needs to be

clamped. I drilled a couple of holes that were extended into

notches. The material is very easy to work and seems more

like

carbon than iron.

The Spin Index did a nice job de-liding a failed TO-5 packaged

transistor. See photos on the

HP

4328 web page.

The hole in the aluminum knob may be a place to put the index pin

when it's not in a vernier hole.

Small rotary tools to go with spin indexer.

|

Stone

|

|

ball end mill

|

The height of the center of the spin index is DIFFERENT than the

height

of the 5C collett holder. This is too bad since it would be

nice

to put a tool (drill bit for example) into one of them and use as

a

hand powered lathe. Need to look for another collet holder

that

matches the spin index.

Things that did Not Work

Tilting Table on Drill Press

The

drill press has a "Feature" that allows the adjustable height

table to

tilt left or right around a bolt that clamps it in

place. But

that also means if you have that table offset, like to hold a

long

object over it's edge, then the downward force of the drill

bit will

tilt the table.

In the photo at the left the 1/2 x 1" iron bar is holding an

eyelet

setting die and the forming die is in the chuck. The

table has

been swung to the left (the chuck is centered over the base

center). When downward pressure is applied the table

tips over to

the right. In this case the fix is to install a 1' piece

of all

thread rod, 4 washers and 4 nuts to make a support for the

table to

prevent it's tipping over, but it's a hassle.

Much better would be a table that does not have the "feature"

of tipping.

Saw

It may be possible to

use a slotting saw to cutoff small rod stock that's being held in

a 5C collet.

This is a 3" x 5/64 cutting edge blade with 30 teeth. The

central

hole is 1". The arbor is the stepped type with diameters

of: 0.995, 0.868, 0.745, 0.618, 0.495. The cap is held

on with a

flat head screw that uses a 3/16" hex wrench.

The arbor shank is 1/2" O.D.

The saw blades come in a number of thickness and diameters.

The

idea is to end up with a rod whose end is square to it's

centerline and

smooth, not the end you get when using a hack saw.

There are a couple of problems. One is the arbor is designed

to

be mounted in an end mill holder (you can see the flat on the

shank in

the photo at the left). Although the arbor could be held in

the

drill press chuck, it may work itself loose. If that

happened and

you had a free spinning saw blade bouncing around like a top there

might be a sefety issue. The other is the pitch of the

saw.

This is a 3" diameter blade with only 30 teeth so the pitch is

PI/10 or

0.314". It's good if the pitch is smaller than what you want

to

saw so that the saw always has a tooth cutting material.

What you

don't want is to have the saw cutting air then the material then

air,

etc.

27 Nov 2007 - Harbor Freight is advertizing a

Mini Cut-off

Saw (

42307)

for $20 that has a 2" blade with 100 teeth (1/16" pitch) turning

at

7,800 RPM that looks like just what I'm looking for. The

Mini Cut-off Saw arrived 8 Dec 2007.

It

weighs 3 pounds and has a 3/4" capacity.

Harbor

Freight 438

4" Cross Slide Vise

Harbor

Freight 438

4" Cross Slide Vise

Since these also come in 5" and 6" sizes I thought the small one

would fit the 8" drill press.

It does NOT fit. There's no way you can position the 4"

cross

slide vise on an 8" drill press and be able to install two

mounting

bolts.

The Enco cross slide table

201-2826

might fit this or a slightly larger drll press. But to try

and

use the drll press as a milling machine the spindle taper needs to

be

MT2, not the JT33 like this 8" drill press.

The

201-2536

"Heavy Duty Mill and Drill Table" is 10 1/2" front to back and 8"

wide, which it way too big to fit the 8" drill press.

The

201-2826"260-512PHSII

Comp

Slde Mill and Drilling Table" has a base that's 5

1/2" wide. It may be an octagon that's 5.5" across the

flats. But how deep the mounting notches are would determine

if

it

just bolts on. This table uses 5/8" T slots, not 1/2" like

the

drll press. The distance between the inside edges of the "T"

slots on the 8" drill press is 3 5/8", so that's the minimum

distance

between the points of the slots in the base of the 201-2826.

Grizzly also sells this table as their

H7979.

Harbor Freight 30999

4" Drill Press Vise

When turned 90 degrees you can get a couple of bolts into the two

rear

holes in the base. But after placing a bolt in the rear of

the

table slot the other vise slot is hanging in the air in front of

the

table. You can use C-clamps.

The movable jaw pivots on the end of the clamp screw. That

allows

the jaws to grip things that are not parallel, but it also can be

akward when clmaping other objects, like a sheet metal part.

What should work is the 2 1/2" Drill Press Vise (Harbor Freight

5927).

Recommendation

If I was shopping for a bench drill

press today it would get the lowest priced one that had a MT2

spindle

taper. If in addition one could be found that had a quill

lock

that would also be good (It may be that the depth stop can be

configured to act as a quill lock). The MT2 is essential if

you

want to have

a go at using the drill press as a milling machine. The

quill

lock is also very important to allow sideways milling where the

height

of the cutting tool is supposed to remain the same. An

alternative to the quill lock would be a rack and pinion height

adjusting system, but that's most likely more coarse than the

quill

adjustment. The price difference is small and gives you more

options. The run out on a drill press is mostly in the 3-jaw

chuck, not the bearings so switching to a collet system would

allow

more precision drilling. This gets more important as the

drill

size gets smaller.

Brooke's Metal Working pages

Links

Harbor Freight -

Enco - note Use Enco is

both their web page URL and their 800 phone number

Back to Brooke's PRC68, Products for Sale,

Military Information, Electronics, Home

page

This is the [an error occurred while processing this directive] time

this page

has been accessed since 21 Nov 2007.

The motor is an AC type rated at 1/3 HP. There are 5 step

pulleys

on both the motor and spindle shafts allowing for 5 speeds of 620,

1100, 1720, 2340 or 3100 RPM. The motor is rated at 1750 RPM

so

there may not be a 1:1 pulley combination. Note with a

pulley

system the motor runs with it's full power potential and the

torque is

traded for speed. One of the dangers of this or any

drill

press is that the drill bit may bind and grab the material.

When

this happens the drill does not stop but instead has the tendency

of

spinning everything and if you hands are holding on they you may

suffer

some pain.

The motor is an AC type rated at 1/3 HP. There are 5 step

pulleys

on both the motor and spindle shafts allowing for 5 speeds of 620,

1100, 1720, 2340 or 3100 RPM. The motor is rated at 1750 RPM

so

there may not be a 1:1 pulley combination. Note with a

pulley

system the motor runs with it's full power potential and the

torque is

traded for speed. One of the dangers of this or any

drill

press is that the drill bit may bind and grab the material.

When

this happens the drill does not stop but instead has the tendency

of

spinning everything and if you hands are holding on they you may

suffer

some pain.

Here is an assortment

of components specifically for 1/2" T slot use.

Here is an assortment

of components specifically for 1/2" T slot use.

Used these to deepen

the countersink in a battery adapter

where the first design used 0.060" thick aluminum but the latest

version used 0.050" thick aluminum and now the 4-40 flat head

screw

bottomed on the PEM insert

rather than seating on the aluminum. So the PEM inserts were

modified by using the countersink.

Used these to deepen

the countersink in a battery adapter

where the first design used 0.060" thick aluminum but the latest

version used 0.050" thick aluminum and now the 4-40 flat head

screw

bottomed on the PEM insert

rather than seating on the aluminum. So the PEM inserts were

modified by using the countersink.

The

drill press has a "Feature" that allows the adjustable height

table to

tilt left or right around a bolt that clamps it in

place. But

that also means if you have that table offset, like to hold a

long

object over it's edge, then the downward force of the drill

bit will

tilt the table.

The

drill press has a "Feature" that allows the adjustable height

table to

tilt left or right around a bolt that clamps it in

place. But

that also means if you have that table offset, like to hold a

long

object over it's edge, then the downward force of the drill

bit will

tilt the table. It may be possible to

use a slotting saw to cutoff small rod stock that's being held in

a 5C collet.

It may be possible to

use a slotting saw to cutoff small rod stock that's being held in

a 5C collet. Harbor

Freight 438

4" Cross Slide Vise

Harbor

Freight 438

4" Cross Slide Vise