Background

Inside Dimension Comparison Ver 1 vs. Ver 2

Power Pole Socket Option Idea

Battery Options

Tested just after charging

Li-Ion Pack

BB-2590

Battery Comparison 13 Oct 2007

Links

Background

This is the second battery adapter

made for the

BA-5590/U family of

military batteries. The battery consists of two independent

"

12 volt" batteries and the

load can be wired to connect them either in series for a "24 volt"

battery or in parallel for a "12 volt" battery. The first

5590BA battery adapter was designed using

0.060" thick aluminum. And these was no planning for the use

of Sub C cells so it's difficult to get 20 SC cells into the first

version. Version 2 holds 20 SC cells close packed with a

little extra room on all sides.

The lid attach method on the first version depended on bending

parts of the lid inward to act as fingers that mate with slots on

the sides of the main box. The combination of the stiffness

of the 0.060" aluminum and the length of the fingers made it

difficult to remove the lid. Version 2 uses 0.050"

aluminum so the sides are more flexible and the inward pointing

fingers have been replaced with what's called a lance. This

is similar to a punch that moves the metal about it's own

thickness and leaves the punched metal attached. Thus the

new "fingers" are much shorter making for easy lid

installation.

The overall dimensions meet the 5" x 4.4" x 2.45" plus zero minus

1/16" outline of the BA-5590/U and the socket is where it's

supposed to be so it's a form and fit replacement for any of the

BA-5590 family of batteries.

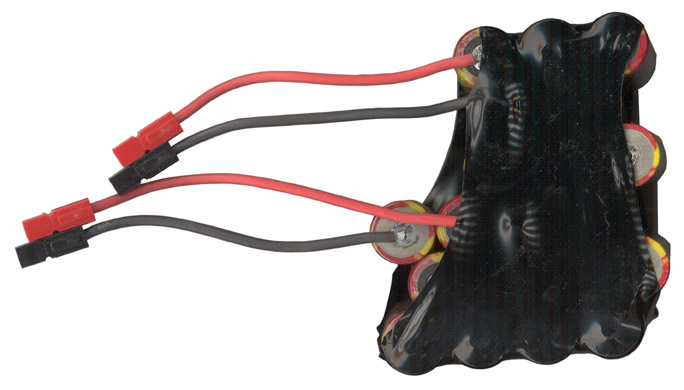

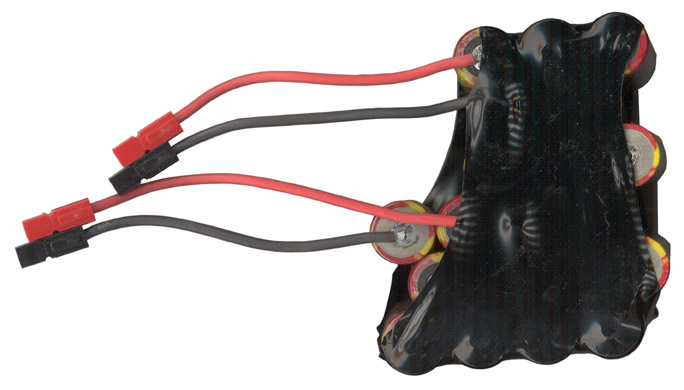

30 April 2008 - top photo (above) shows 12 AWG wires with crimped

connections. The wire is super flex, i.e. there's a large

number of very fine wires, not the stranding like used for house

wiring. They measure 1 milli Ohm each including the Power

Pole terminal and the socket pin. For more see the

HP 4328A Milliohmmeter web page.

The adapter without any batteries weighs about 9 oz.

Inside Dimension Comparison Ver 1 vs. Ver 2

|

Ver 1

|

Ver 2

|

Delta

|

20 SCPack 0.9"

|

High

|

4.729

|

4.876

|

+0.147

|

4.798

|

Wide

|

4.250

|

4.278

|

+0.028

|

4.050

|

Deep

|

2.245

|

2.335

|

+0.090

|

1.930

|

Power Pole Socket Option Idea

2019 The Paul Buff Vagabond

Battery Pack for the E640 Studio Strobe light has a Power

Pole connector.

28 Oct

2007 - Boxes back from laser marking. A pair of power pole

connectors will pass through the wire clearance hole below the

socket. If there is enough slack in the battery pack wires

they could be threaded through the hole one pair at a time then

coupled into a 4 terminal block. The blue support blocks could

then be used to anchor the block of connectors to the existing

bracket which would need a couple of holes drilled and a spacer

between the connector block and the bracket.

28 Oct

2007 - Boxes back from laser marking. A pair of power pole

connectors will pass through the wire clearance hole below the

socket. If there is enough slack in the battery pack wires

they could be threaded through the hole one pair at a time then

coupled into a 4 terminal block. The blue support blocks could

then be used to anchor the block of connectors to the existing

bracket which would need a couple of holes drilled and a spacer

between the connector block and the bracket.

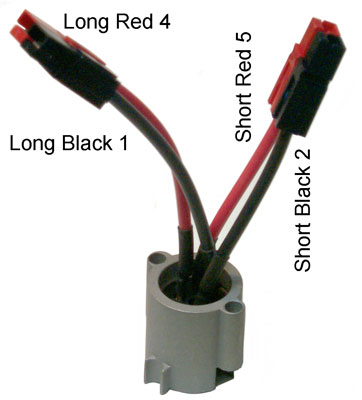

The photo shows a two pair of Power Pole connectors where each pair

is the ARES standard configuration, but they are stacked. That

way you could plug in two independent "12 volt" ARES loads or make a

jumper cable to get 24 volts. For some ham radio applications

the high current output would support short transmissions where high

current is needed.

If the blue support blocks are not used a 3/32" cotter pin passing

through the hole in the connector block, going through a spacer and

a single new hole in the bracket would also work. The

connector block would have some "wiggle" and that's a good thing

since the connector should have some play.

The SC cells

used in RC racing cars have the ability to run at (30 Amps 2006

(2008 40 Amps) so an option for this battery adapter may be (idea

stage) to use a different socket bracket to support Anderson Power

Products "

Power Pole"

connectors using contacts rated for 45 Amps.

Twenty SC cells in series would have a voltage of about 24.0 when

empty and with a current of 30 amps would be delivering 720

watts! The parallel configuration would be 12 volts at 60

amps for 720 watts!

That's a lot of power.

The DARPA

Wearable

Power $1,000,000 contest is asking only for 200 Watts max

power, but they want about 2 kWhrs weighing no more than 4 kg (8.8

pounds). With 4.5 AH SC cells the capacity of the adapter

would be about 20 * 1.2 V * 4.5 AH = 108 Whrs far short of the

2,000 Whrs they are looking for. They specified the two

voltages as 10 to 16 VDC and 20 to 32 VDC. This is

interesting because it eliminates Li cell batteries that produce a

little more and have been know to blow out some equipment

(Javilin) that can not handle the higher voltage.

The version 2 adapter weighs 3 ¼ pounds with the 3.3 AH SC cell

pack, maybe a little more with 4.5 AH cells.

To support the Power Pole high current idea the internal wires

need to be 14 ga or larger.

15 Oct 2007 - A sample of 14 ga wire is on order to see if it will

fit the connector pin solder cup (the dimensions say it's a little

too big).

22 Oct 2007 - The 14 AWG wire will work with the connector solder

cup. Wire on order, here in a couple of days.

If the regular socket is used it makes sense to use the heavy wire

to minimize IR drop even when lighter loads are being powered.

The problem is soldering the wire. Extremely

difficult. The solution is to crimp the 14 AWG wire into the

brass connector pin.

Battery Options

SC Pack

14 May 2008 Charging and discharging

to see if capacity improves (what I was told).

|

|

Triton2

Charger & 4.7 AH 20 cell Pack

|

Load Testing EL1132 Electronic Load

controled by Sony Viao w/ LabVIEW

|

|

Life

Size

(72 dpi) image showing Power Pole Connectors partially

separated.

Red

is

Receding.

If you remember this alleration when it comes time to

seperate a pair of Power Pole connectors you will know to

push on the front of the red shell and support the back of

the black shell.

|

The Triton2 charger can charge all 20 cells in series. The

wires on the battery pack do not have the Power Pole connectors

impermanently paired up so they can easily be connected in

series. But the Triton2 has a charging power limit of 90

Watts so for a 28 Volt pack the current can only get to 3.2 Amps

(which is what's shown in the photo at left) even though the set

current was 4.0 Amps. The set current would be used if the

pack voltage was below 22.5 Volts.

In a similar manner the discharge is limited to 20 Watts, which

for a 28 volt pack is only 0.7 Amps, not really enough to do

much. By load testing the two sides separately that can be

doubled to 1.4 Amps, but still short of a realistic load.

You can see the thermal sensor plugged between the pack shrink

wrap and the center cells. So far it has not terminated

charging but is a safety backup.

12 May 2008 - the battery pack weighs 3 lbs 1.5 oz.

When in the 5590BAv2 that total would be 3 lbs 11 oz.

At a

constant 2 amps discharge it lasts about 4.1 hours (about 8 AH

capacity).

11 May 2008 - Using 9 min Rx @ 320 ma & 1 min Tx @ 1.7 Amps,

series connected 20 volt cuttoff. The run time is 9.5

hours.

That's equivalent of over 17 Amp

Hours although these cells are rated 4.7 AH. Compared to

the 40 Amp loads they are designed to deliver the radio loads

are much lighter, increasing the Amp Hour capacity.

5 May 2008 - The pack is here and fits perfectly. See top

photo on this page. Now for some electrical testing.

There are 20 each 4.7 AH cells in this pack.

Capacity is 20 cells * 4.7 V/cell*

1.2V = 112 Watt Hours!

2 May 2008 - The pack can be ordered from

Cheap Battery Packs

soon with a predefined configuration.

20 Elite 4 AH cells, copper bars, 14 AWG wire PRC68 configuration

less than $150 including shipping to California YMMV

20 cells * 4 AH/cell * 1.2V discharged = 96 WH, at 1.3 Volts

average maybe 104 WH so around 100 WH capacity. These cells

are rated to discharge 40 Amps.

That's 40A * >24V >= 960 Watts. But the 5590 type

connector can not support 40 Amps for very long. An option

would be to replace the 5590 socket with Power Pole connectors.

If the discharge rate was 1,000 Watts and the capacity is 100 WH

then the time would be 0.1 hours or 6 minutes. That's way

too long for the 5590 connector would not take it.

When used in a radio the advantage is that the voltage drop during

transmit will be lower than with a higher resistance battery and

so you get more talk time in transmit.

11 Nov 2007 - The reason for my

current focus on the high current performance is not so much that

the load would be drawing huge currents all the time, but on the

need to be able to supply a current higher than the average

current for short periods of time. Many devices have a

startup power requirement that's considerably higher than their

run current. If the battery can not supply the starting

power then it can't power the equipment. Also by designing

for the higher currents resistive losses are lowered for the lower

currents.

1 Nov 2007 - The 20 SC pack made for

the first version 5590BA has been refitted with 14 AWG wire and

Power Pole connectors with

45 Amp contacts. It

drops right into the 5590BAv2.

A

Triton2 Charger Discharger Cycler

is being used to get this pack up and running since it's been

sitting for many months. The discharger can be used to

evaluate how well another charger works with a limit of 3 Amps

max. The Amrel EL1132 can handle 300 watts, which at 28

Volts is a little over 10 Amp discharge current. Testing at

30 Amps from 30 Volts requires a resistor of about 0.9 Ohms that's

good for about 900 Watts. Not easy to come by.

This pack requires a height of 4.798" and width of 4.050" when

0.900" dia SC cells are used close packed. You can see in the

comparison table they will not fit in version 1 but have room to

spare in version 2.

The pack was made in 2005 and has been sitting for over a

year. Using the Battery Space charger then load testing there

was almost no charge. The old 18 AWG wires and 15 Amp Power

Pole connectors have been replaced with 14 AWG super flex wires and

45 Amp Power Pole connectors. Using the Triton2 charger in cycle mode

produced these input and output capacities:

Cycle #

|

Charge

|

Discharge

|

% D/C

|

1

|

2917

|

2040

|

70

|

2

|

2873

|

2533

|

88

|

3

|

2872

|

2543

|

89

|

Not bad, still in spec at Nov 2007.

Next getting ring terminals to make test cable for Amrel EL1132 Electronic Load to allow

testing battery pack using 45 Amp Power

Pole connectors instead of the 10 Amp rated 5590 connectors.

Load Test 2005 SC Cell Pack

9 Nov 2007 - The test was done using the Power Pole connectors on

the battery pack, not using the 5590BA socket that's probably rated

for only 10 Amps. Two sides connected in series.

I

|

V

|

Watts

|

1

|

26.18

|

26

|

2

|

26.0

|

52

|

3

|

25.75

|

77

|

4

|

25.5

|

102

|

5

|

25.2

|

126

|

6

|

24.8

|

148

|

7

|

24.5

|

171

|

8

|

24.2

|

194

|

9

|

23.8

|

214

|

10

|

23.6

|

236

|

11

|

23.3

|

256

|

12

|

23.0

|

276

|

13

|

22.8

|

296

|

14

|

22.6

|

316

|

15

|

22.5

|

3371

|

Note 1 - The EL1132 is rated for

300 Watts and at 337 Watts it started making beeping sounds, so no

higher currents were tested. The limitation is the tester, not

the battey.

Using Excel to fit the V vs. I data gives the equation: y =

-0.2847x + 26.526 where the resistance of the battery and test wires

is 0.28 Ohms and the open circuit voltage is 26.5 Volts.

R2 = 0.9932 is a measure of the quality of fit. When this same

pack was tested in the first version 5590BA (including the socket)

with 18 ASW wires on the pack and 15 Amp Power Pole connectors the

internal resistnace was 0.35 Ohms. At 5 Amps in the old thest

the voltage was 26.1, a little higher than this test. Maybe

the pack is older or not fully charged. Will try again right

after charging.

Tested just after charging.

I

|

V

|

Watts

|

0.1

|

27.9

|

3

|

1

|

27.7

|

28

|

2

|

27.5

|

55

|

3

|

27.3

|

82

|

4

|

27.0

|

108

|

5

|

26.7

|

134

|

6

|

26.4

|

158

|

7

|

26.0

|

182

|

8

|

25.6

|

204

|

9

|

25.3

|

228

|

10

|

24.85

|

249

|

11

|

24.5

|

270

|

12

|

24.3

|

292

|

13

|

24.0

|

312

|

14

|

23.8

|

3611

|

Note 1 - The EL1132 is rated for

300 Watts and at 361 Watts it started making beeping sounds, so no

higher currents were tested. The limitation is the tester, not

the battey.

When the I V data is plotted in Excel equation for the points

is:

y = -0.3186x + 28.153 R2 = 0.9935 Note the open circuit

voltage is now higher, about 1.41 Volts per cell.

For an output voltage of 20.0 (where most "24 Volt" equipment turns

off) the current according to the equation would be 25.6 Amps for

these two year old Ni-MH cells.

20 Volts @ 25.6 Amps is 512 Watts for these two year cells rated 3.3

AH. Twenty cells @ 1.2 volts would be 79 Watt hours so at 512

Watts would run for maybe 9 minutes.

Checking a couple of SC cell suppliers:

http://www.cheapbatterypacks.com/?sid=853305&pgid=loosecells&chem=NIMH

is showing Ni-MH: 4.5 AH cells $ 7.35 each and 2.2 AH $ 4.65

Ni-CAD: 2.4 AH @ $5.75 and 1.3 AH @ $4.35

http://www.batteryspace.com/index.asp?PageAction=VIEWCATS&Category=226

is showing set of 20 matched Ni-MH 4.2 AH @ $ 4.30, 4.5 AH about $8

http://www.batteryspace.com/index.asp?PageAction=VIEWCATS&Category=296

Ni-Cad: 2.1 AH @ $ 2.30

This is probably because the 4.6 Ah rating was at much higher

currents (up to 10C).

4.6 Ah Rated (17 Ah Tested) Ni-MH Pack

|

added 17 Nov 2009

This Ni-MH pack was custom made off shore since I haven't

been able to find high current rated cells in the U.S.

They are rated 4.6 Ah (30 Amps for 8 min = 4 Ah). But

when tested using the electronic load with the following

parameters:

0.32 Amps for 9 minutes

1.70 Amps for 1 minute

with an ending voltage of 20.9 V

the capacity was 17 Ah. |

2.6 Ah Rated Li-Ion Pack

|

added 17 Nov 2009

The two battery packs are model LCH4S4R1WR and the charger

is model CH-LI4`8-4 both from Battery Space with

a total about $230.

The battery packs come with shrink tube at the ends of wires

and I've added the Power

Pole connectors. The packs contain four series

18650 size cylindrical Li-Ion cells rated 2600 mAh.

Also as part of the pack is the protection PCB.

The charger is specific for a 14.8 V pack. |

|

The two packs take up a small

amount of space but there's not enough room to hold 4

packs. Maybe a custom pack with staggered cells would

allow twice the number of cells, i.e. 16 cells instead of 8

cells.

You can see the bulge in the shrink wrap where the PCB is on

right of each battery pack in the photo on the left.

|

BB-2590

The above 2.6 Ah dual pack is a Li-Ion solution with 4 cells

per 12 Volt battery (8 cells total). The BB-2590 uses a

32P4S pack for each 12 Volt battery (24 cells total).

None of the extra top contacts are needed for a BB-2590 since

it has internal protection against over charge and over

discharge as well as over temperature. But I don't think

the BB-2590 has any call balancing capability.

So the ideal battery pack may consist of 24 cells of 18650 size

with the highest AH capacity (the high discharge current cells

(2016: up to 30 Amps) that are used for electrical vehicles,

like the Tesla line of cars, are not needed for this application

since the loads are under 10 Amps and more typically under 3

Amps.

Photo shows 8 cells on bottom layer and

room for 3 cell high stack

for a total of 24 cells. Plus room for a PCB under

the lid and

room for the Power Pole cables under socket.

|

|

Battery Comparison 13 Oct 2007

Table based on user made battery pack. i.e. neither labor to

make pack included nor cost of misc links, connectors, wire, etc.

Make

|

Cell

Size |

Chem

|

AH cap

|

$/cell

|

#

cell

|

Watt hrs

per pack

|

$/pack

|

$/Wh

|

| ELITE4500 |

SC

|

Ni-MH

|

4.5

|

7.35

|

20

|

108

|

147

|

1.36

|

| ELITE3600 |

SC |

Ni-MH

|

3.6

|

4.95

|

20

|

86.4

|

99

|

1.15

|

4200

|

SC |

Ni-MH

|

4.2

|

4.30

|

20

|

100

|

85.95

|

0.85

|

2100

|

SC |

Ni-Cad

|

2.1

|

2.26

|

20

|

50.4

|

22.95

|

0.46

|

10xAA

(4 packs)

|

AA

|

Ni-MH

|

2.2

|

2.60

|

40

|

106

|

103.80

|

0.98

|

2600

(in b. holders)

|

AA

|

Ni-MH |

2.6

|

1.43

|

20

|

62.4

|

28.60

|

0.46

|

| LS91

(in b. holders) |

AA

|

Li-FeS2

|

3.0

|

1.97

|

20

|

72

|

39.35

|

0.55

|

4.6 Ah

Rated

(17 Ah meas)

|

SC

|

Ni-MH

|

17.0

|

na

|

20

|

408

|

na

|

na

|

2.6 Ah

rated

|

18650

|

Li-Ion

|

2.6?

|

21

|

8

|

71

|

170

|

2.40

|

The 5590BAv2 may be sold as the box

with secondary style socket terminated with short super flex 16

AWG wires terminated with a pair of 45 Amp rated

Power Pole connectors (4

terminals) in standard ARES configuration. And also offer

optional battery packs.

20 SC Cell Packs

Packs are made using either spot welding or soldered copper link

bars. The table above shows only a few of the SC cells that

are on the market. Since the 0.9" diameter cells easily fit

ver 2 commercial packs can be made without custom fitting.

The SC pack I made for version 1 just drops in with room to spare.

An interesting prospect is the ability of delivering 30 amps at 30

volts or 60 amps at 15 volts, i.e. 900 Watts. The cells and

wiring are up to it but I don't know about the connector.

I've heard that each contact can handle 10 Amps, i.e. good for

delivering 10 A @ 30 V or 20 A @ 15 V for 300 Watts.

40 AA Adapter

This would be an adapter that can hold 40 AA cells. It

allows the use of Alkaline, Ni-Cad, Ni-MH, LiFeS4 (Energizer L91

1.5 volt Lithium),

Sanyo eneloop

Ready To Use (long shelf life) Ni-MH, or whatever new

chemistry comes out in the future. AA cells typically are

where the newest technology shows up first. Short wire leads

with Power Pole connectors. A string of 10 cells gives 15

volts so 20 cells is the number needed for the two sides to the

5590 family battery. So you could install just 20 cells or

for more capacity install all 40.

I'm investigating the eneloop

Ready

To Use Sayno AA cells. They claim a much longer shelf

life than other Ni-MH cells. This is being done with a Maha

C9000.

CR123 Photo Battery Adapter

The same idea as for the AA adapter, except for the CR123 photo

batteries. These are 3 volt cells so a string of 5 gives 15

volts so 10 cells is the minimum number to have a working 5590

family battery, adding multiples of 10 cells to give 20, 30, 40 or

maybe 50 cells adds capacity.

Links

back to Brooke's: PRC68, Battery, BA-5590/U

Family, 5590BAv1, Battery Patents, Military Information, personal home, Alphabetical list of web pages

page created 15 Oct 2007

28 Oct

2007 - Boxes back from laser marking. A pair of power pole

connectors will pass through the wire clearance hole below the

socket. If there is enough slack in the battery pack wires

they could be threaded through the hole one pair at a time then

coupled into a 4 terminal block. The blue support blocks could

then be used to anchor the block of connectors to the existing

bracket which would need a couple of holes drilled and a spacer

between the connector block and the bracket.

28 Oct

2007 - Boxes back from laser marking. A pair of power pole

connectors will pass through the wire clearance hole below the

socket. If there is enough slack in the battery pack wires

they could be threaded through the hole one pair at a time then

coupled into a 4 terminal block. The blue support blocks could

then be used to anchor the block of connectors to the existing

bracket which would need a couple of holes drilled and a spacer

between the connector block and the bracket. The SC cells

used in RC racing cars have the ability to run at (30 Amps 2006

(2008 40 Amps) so an option for this battery adapter may be (idea

stage) to use a different socket bracket to support Anderson Power

Products "Power Pole"

connectors using contacts rated for 45 Amps.

The SC cells

used in RC racing cars have the ability to run at (30 Amps 2006

(2008 40 Amps) so an option for this battery adapter may be (idea

stage) to use a different socket bracket to support Anderson Power

Products "Power Pole"

connectors using contacts rated for 45 Amps.