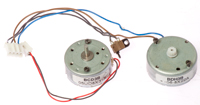

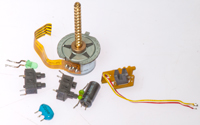

June 2015 - I'm interested in the DC PM motors with a 3.17mm

(1/8") shaft because they are reasonably priced ($3 to $11) and

are commonly used in RC vehicles that are about 1 foot in

size. The shaft diameter of a motor is related to it's

power output, for 1/8" shafts that amounts to about 50 to 200

Watts (746 Watts is 1 horsepower).

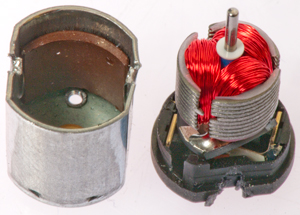

For a given shaft size the armature and frame magnetics will be

about the same. The main variation is in what size wire is

used to wind the armature and that relates to how many turns

will fit.

The best short paper on permanent magnet DC motors is "Characteristics

of DC Motors.pdf" by Rutgers Prof. Dunbar P. Birnie.

Mabuchi Model Numbers

Mabuchi Motors -

Technical Guide - Part

Number List

Decoding Mabuchi part numbers: L1L2-N1N2N3L3L4-N4N5TTTT

L1 Shape: Flat (F), Round (R), Square (S)

L2 Brush: Metal: (A, E), Precious

Metal (F), Carbon (C, H, K, S, T, Z)

N1 Armature Diameter: small lto large (J, K,

M, N, 1, 2, 3, 4, 5, 6, 7, 8)

N2 Housing Length code:

N3 Number of Armature Poles: 3 (0), 5 (5), 6

(6), 7 (7), 8 (8), 10 (A), 12 (B)

L3 Magnet: C Isotropic (R), Ring Isotropic (T),

Anisotropic or Rare-Earth (P, S, V, W), Rubber (C, E, F)

L4 Custom Design: Encoder (W)

N4 wire diameter tenth of mm: If number tenths of

mm, if letter A = 1mm

N5 wire diameter hundredths of mm: 0.01mm (1),

0.05mm (D), 0.055mm (Z)

TTT Turns per slot: might be 2, 3 or 4 digits.

Notes:

Stall Torque and Stall Current are proportional to

1/(wire_diameter^2) - I tried this on some data and at first

glance I don't see the correlation.

Pwr out (Watts) = [N (rpm) * T (mN-m)]/9550

The 4 cardinal performance points are: No load RPM and Current,

Stall Torque and Current.

Units

K is the relationship between applied voltage (Volts) and the

speed in radians (Wiki)

per second (symbol w). Since speed is commonly given as

Revolutions per Minute that needs to get converted.

RPM / 60 = Rev Per Second (RPS).

RPS * 2 * PI = Radians per second

For example a For the Mabuchi RS-545SH: motor

that turns 6800 RPM at 12 Volts has w = 2* PI * 6800 / 60 = 712

radians per second.

The electrical circuit looks like a constant voltage drive,

routed through the internal resistance of the armature to a

virtual battery whose back EMF (Vbemf) is determined by the

motor RPM.

Vbemf = K * 2* PI* Rev/Sec

or

K = Voltage / (radians per sec) , = 12 / 712 = 0.01685

The electrical equation is:

Vdrive = I * Rinternal +Ebemf

Then:

Tstall = K * V / R

"Turns" refers to the number of times a wire is wound around

one of the poles of the armature.

For example the Gilbert

DC Motor (used in Erector Sets)

has a 3-pole armature and each pole maybe a couple dozen turns.

The force on a wire in a magnetic filed depends on the magnetic

field strength and the current in the wire. Since the

magnetic field is fixed for a given motor the torque depends on

the number of turns and the current.

For example

The Mabuchi

RS-550PC (see below) we know at 7.2 V drive the no load speed is

supposed to be 13500 RPM.

So K = 2 * PI * 13500 / 60 = 1414

The stall torque is given as 3700 g-cm with a current of 83

Amps. The back EMF at stall is zero, so

R = V / I = 7.2 V / 83A = 0.0867 or 86.7 milli Ohms.

Measuring R Directly

Note: A direct measurement of R is very difficult.

If a DC measurement is made there will be errors because any

dissimilar metals will generate DC voltages that are unknown,

see my web page on Kelvin (4-wire)

resistance measurements. The 50 milli Ohm limit of

the HP 34401 DMM is very close to the resistance of the RS-550PC

motor.

A direct measurement using an AC test method will have an error

because of the inductance of the windings. See the HP 4328 Milliohmmetere web page for

an example.

It may be possible to make a swept frequency impedance

measurement using the HP 4395A and by fitting the data to an

equivalent circuit separate the real and imaginary parts.

This may also be possible using an LCR meter that has a series

equivalent circuit representation, like the HP 4274 & HP 4275 LCR meters.

Back EMF (Wiki)

When the armature is stalled there is no back EMF, but as soon

as the armature is turning it's generating a back EMF that

subtracts from the applied voltage thus reducing the armature

current. Vbatt -Vemf = Iarm * Rarm.

Note if the motor has it's shaft turned by an external torque

then it will act as a generator and the voltage is exactly the

same as the back EMF (assuming the load resistance is very high,

i.e. not using the generator to power something, just using a

high impedance meter to read the voltage).

Back EMF [Volts] is proportional to (magnetic field

strength[Webers]) * (total number of wires[no units]) *

(rotational speed[RPM]) / 60 [convert RPM to RevPerSec]

Note: If the power circuit to the motor is opened and a

high input impedance voltmeter is across the motor terminals it

will read the back EMF.

Tried this on an RS-555 motor where the supply was set to 18.0

Volts. With the power applied the DMM reads 18.0 volts and

when the power is disconnected the voltmeter reads about 17.9

Volts and as the motor spins down the voltage drops.

Stall Current

For the Mabuchi RS-545SH:

Nominal spec: 6800 RPM @ 12 Volts, K= 0.01685

The no load current in in the range 0.25 to 0.3 Amp, Torque (no

load) = 0.25A * 0.001765 Volts/RPM =

Voltage

|

Stall

Amps

|

No Load

Amps

|

Rstall

Ohms

|

3

|

1.18

|

0.25

|

2.54

|

4

|

1.60

|

0.26

|

2.50

|

5

|

2.02

|

0.28

|

2.47

|

6

|

2.32

|

0.28

|

2.58

|

7

|

2.78

|

0.29

|

2.51

|

8

|

3.25

|

0.29

|

2.46

|

9

|

3.6

|

0.28

|

2.50

|

10

|

3.7

|

0.29

|

2.70

|

The motor resistance is about 2.5 Ohms including the wires from

the power supply.

Note: A key thing about these is that they can produce a lot of

torque when the shaft is stalled. Internal Combustion

Engines (ICE) need to be running at some speed in order to produce

torque. This is why Diesel Electric Locomotives are so

popular, i.e. they have a lot of torque at zero speed. BUT .

. . a lot of attention needs to be paid to cooling the motor since

overheating can easily burn it out.

Starting Current

In June 2015 I got some RS-775 type motors that have a 5.0mm

shaft diameter to work with a family of flywheel/pulleys.

When powered by an HP/Agilent/Keysight E3617A power supply (0 to

60 Volts at up to 1 Amp) the motors will not start

spinning. But on power supply, like the HP 6038A that can

supply higher currents the motor spins up.

Self Starting

A 2-pole motor may not start when power is applied and will

turn in either direction depending on the direction of the

initial manual spin. Motors with 3 or more poles will self

start and run in the same direction for the same input polarity.

Efficiency

Efficiency is a measure of the power output compared to the

power input.

When a motor is running with no load it has zero efficiency

because there's no useful power out. So the lower the

power consumed when the motor is running at no load the better.

Note: At "no load" there really is a small load because

of bearing friction and wind loss. There are some Youtube

videos where the presenter was proud of the high power consumed

by his motor when running at "no load", that's a big mistake.

May of the YouTube home built DC motors that claim "over unity"

or "zero point energy" are being evaluated on their electrical

input power and electrical output power and the mechanical

output power is never evaluated. One of the presenters

went to some effort to describe how to make a small dynamometer

but never showed it being used on any of his "motors". So,

the so called "motors" are not really motors but rather DC to DC

converters and so are misnamed "motors". Note that

measuring electrical power when the current is either DC or a

sine wave is straight forward, but when it's a more complex

waveform it's difficult to make power measurements. Many

of these "motors" can be seen as works of dynamic art and are

fun to look at when they are running.

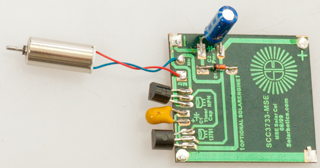

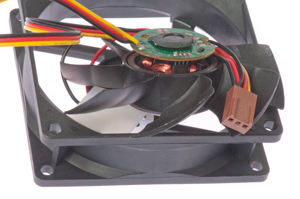

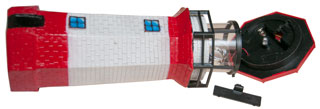

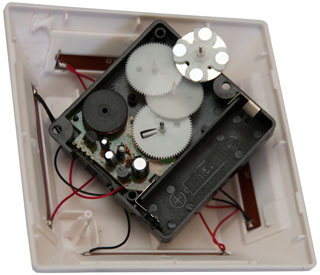

Pager Motor

This Miller Solar Engine (MSE) circuit runs the motor for about

10 seconds. The times vary depending on how bright the

light is.

On a cloudy day it might be six minutes between runs of 6

seconds, and in direct noon sun it might be 11 second runs every

10 seconds.

The circuit works by the solar panel (the back of the panel has

the MSE ciruict shown in the photo) charges up a 0.33F super cap

and when the 1371 gets to it's trip voltage a pin is grounded

turning on a transistor that connects the super cap to the

motor. The 1371 has it's own capacitor with isolation

diode so that it will remain on even after the super cap voltage

goes below the trip point.

I expect with some glue circuitry a number of these can be

connected in series to provide higher voltages and larger value

super caps can be used.

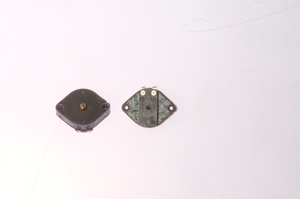

Maxon A-max

26mm dix x 57mm overall

Motor body length: 44.65mm

2.97mm dia shaft with flat x 10.73mm long

Six threaded holes on shaft end, size & location TBD.

Motor starts to turn at 0.07V and draws 12ma.

V

|

ma

|

RPM

|

0.07

|

12

|

|

1.0

|

19

|

|

1.5

|

22

|

|

3.0

|

32

|

|

|

6x<M3

17.4 dia?

|

|

Maxon makes some very high end motors with much better

specifications than you get from a pager motor. Instead of

the under a dollar that a new pager motor costs, these go for

about $100 each new and are not often on the surplus

market. Supposed to have very low no load power and be

very efficient.

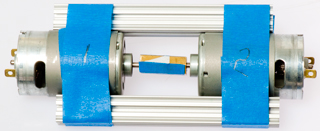

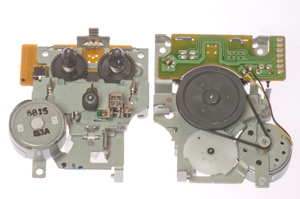

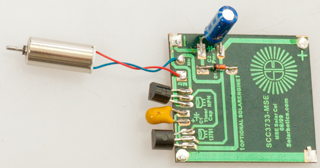

Mabuchi RS-550PC permenant magnet DC carbon

brush motor & DT2234A+ digital Optical tachometer

Aluminum foil and painters blue tape wrapped around gear

for tachometer.

|

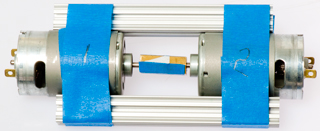

Two RS-550PC Motors

coupled for measurements

Blue tape on coupling to stop reflections, triangle is

reflective strip.

|

Dual motor test done using:

HP 6038A 0 - 60 V 0 - 10

A Power Supply

Two RS-550PC Motors coupled so No. 1 is motor and No. 2 is

generator

High Power Load from Tamaya

Grasshopper RC car Mechanical Speed Control

Optical Digital Tachometer DT2234A+

|

|

| Volts In |

Amps In |

Watts In |

RPM |

Volts Out |

Amps Out |

Watts Out |

R In |

R Load |

| 3 |

0.64 |

1.9 |

869 |

1.96 |

0 |

|

4.7 |

|

| 1.25 |

3.8 |

476 |

0.22 |

0.037 |

0.008 |

2.4 |

5.8 |

| 4 |

0.74 |

3.0 |

1295 |

2.96 |

0 |

|

5.4 |

|

| 1.54 |

6.2 |

721 |

0.32 |

0.048 |

0.015 |

2.6 |

6.6 |

| 5 |

0.73 |

3.7 |

1661 |

3.75 |

0 |

|

6.8 |

|

| 1.80 |

9.0 |

895 |

0.42 |

0.043 |

0.018 |

2.8 |

9.7 |

| 6 |

0.77 |

4.6 |

2075 |

4.70 |

0 |

|

7.8 |

|

| 2.09 |

12.5 |

1112 |

0.61 |

0.042 |

0.025 |

2.9 |

14.4 |

| 7 |

0.61 |

4.3 |

2589 |

5.86 |

0 |

|

11.5 |

|

| 2.33 |

16.3 |

1354 |

0.64 |

0.042 |

0.027 |

3.0 |

15.2 |

| 8 |

0.43 |

3.4 |

3014 |

6.80 |

0 |

|

18.6 |

|

| 2.38 |

19.0 |

1609 |

0.71 |

0.055 |

0.039 |

3.4 |

12.9 |

| 9 |

0.44 |

4.0 |

3516 |

7.92 |

0 |

|

20.5 |

|

| 2.64 |

23.8 |

1946 |

0.85 |

0.062 |

0.053 |

3.4 |

13.7 |

| 10 |

0.44 |

4.4 |

4086 |

9.06 |

0 |

|

22.7 |

|

| 2.85 |

28.5 |

2202 |

0.90 |

0.074 |

0.067 |

3.5 |

12.2 |

| 11 |

0.47 |

5.2 |

4468 |

10.06 |

0 |

|

23.4 |

|

| 3.15 |

34.7 |

2432 |

1.01 |

0.06 |

0.061 |

3.5 |

16.8 |

| 12 |

0.56 |

6.8 |

4954 |

11.05 |

0 |

|

21.3 |

|

| 3.42 |

41.0 |

2652 |

1.08 |

0.084 |

0.091 |

3.5 |

12.9 |

RPM = 390.51 * Vin with motor #2 as open circuit load.

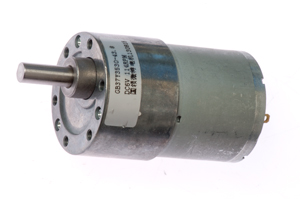

This is a carbon brush permanent magnet DC motor (Data

sheet).

Some specs:

Operating Voltage 6.0 - 9.6, Nominal 7.2 VDC

No Load Speed 15,300 RPM @ 1.4 Amps

At Max Efficiency: 13, 540 RPM, 10.8 Amp 41.7 mN*m, 425 g*cm,

59.1 Watts

Stall Torque 363 mN*m, 3700 g*cm @ 83 Amp

25mm diameter x 75mm overall length

3.17mm OD x 8.7mm shaft.

2x M3 mth holes 24.3mm apart?

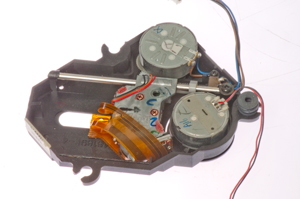

Mabuchi RS-555PH-3255

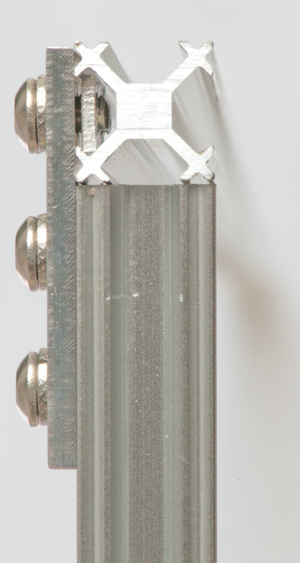

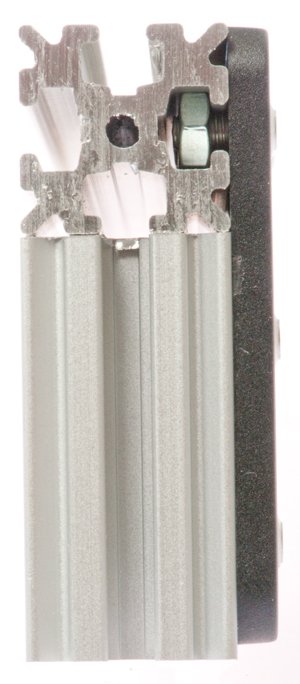

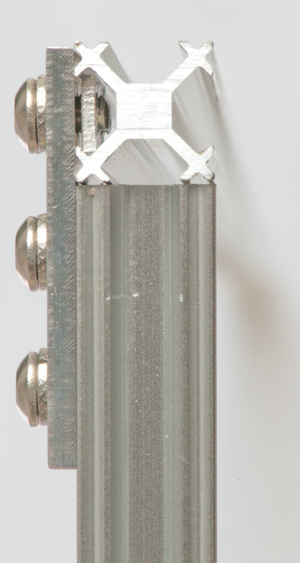

Beams & Construction Supplies

T-Slot beams are handy for making stuff.

Comparison of the starter Kits.

Brand

|

Weight

|

Size

|

Longest Beam

|

End

Section

|

MicroRAX

|

2# (includes extras)

|

2" dia x 3' tube |

35-3/8" (898.5mm) |

|

MakerBeam

|

3 # 4 oz

|

11.5" x 9" x 1" box |

11.8" (300mm)

|

|

OpenBeam

|

2#

|

9.5" x 7" x 2" |

6" (152mm)

|

|

MicorRAX is the lightest weight (strength), OpenBeam is

stronger and MakerBeam is strongest of these three (intended

for making 3D printers?)

MicroRAX

MicroRAX - 10x10mm beam,

uses M3 fittings but with special narrow nuts (Starter Kit

received 11 July 2013)

The 3 beams that come as part of the starter kit are 35-3/8"

(898.5mm) long.

I think the Harbor Freight Mini Cut Off

Saw will make cutting the beam easy.

2" dia x 3' tube

2 pounds

|

Inside tube

|

Starter Kit + some extras

|

|

|

Right Angle bracket

Uses standard M3 screws & lock washers.

Need 2mm hex bit (not the 1.5mm bit that was also

shipped)

|

|

Starter Kit (3 beams not shown) $80

|

|

|

Nut plates instead of standard nuts to

fit into the small T-slot.

|

|

Extra Parts in addition to the starter

kit $40

Tri-Corner

PCB Standoff Kit

Mounting Bracket for 1/4"

Joining Plate Truss Style

Joining Plate Corner Style

|

|

|

|

|

|

|

|

MakerBeam

MakerBeam.EU - is a 10 x

10mm beam, uses M3 fittings - from Europe (Starter Kit on order)

Like:

When joining two beams to make a right angle corner they fit

well. Haven't checked the angle.

Metal brackets.

You can attach nuts to screws and brackets then slide into beam.

Good variety of brackets.

Dislike:

Using special square headed M3 screws, are they readily

available?

11.5" x 9" x 1" box 3 lbs 4 oz

|

Contents of Starter Kit

|

|

Corner Joint showing special square

headed M3 screw

|

End of Beam with screw

|

|

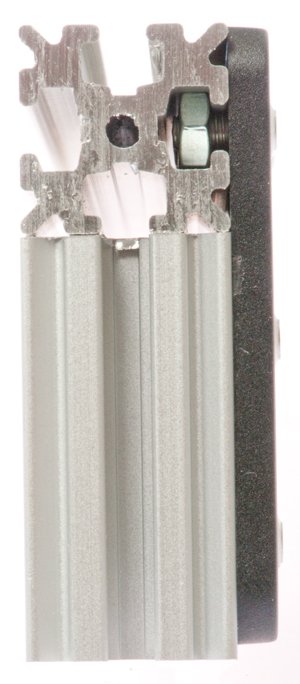

OpenBeam

OpenBeamUSA - is a

15x15mm beam, uses M3 fittings - hard to get (Received 11 July

2013) $80

comes with:

2 packages of 8 plastic L Brackets

1 packages of 8 plastic T Brackets

1 bundle of 12 each 6" Beams

A bag of screws

A bag of nuts

A 1mm ball end hex wrench

Like:

Uses what appear to be standard M3 hex head screws and nuts.

The corners of the beam are designed to be the rails for a

linear motion system.

You can attach nuts to screws and brackets then slide into beam.

Dislike:

Plastic brackets with sloppy holes.

Burs where beam has been cut.

9.5" x 7" x 2"

2 pound box

|

|

|

|

80 20 Inc - offers 20x20mm

T-slot extrusions and larger sizes, also inch sizes

T-Slots - offers 2x2" or

50x50mm and larger extrusions

Parco Inc - 10x10mm

- Joining

Plates - fractional

fasteners -

MiniTec - they have

an 11x19mm (1 slot) & 19x19 (2 slots), not the slot on each

face like the above products.

MakerSlide

- for linear motion (related to Vslot and/or V rail?)

Faztek - useless web pages

Tamiya Pulley Unit Set

TAM70121 - (Kit on order)

Tamiya Pulley (L) Set

TAM70141 - (Kit on order)

Tamiya Pulley (S) Set

TAM70140 - (Kit on order)

Phidgets

T-Slot

Primer - very innovative ways of making connections,

much more so than the above.

20,

30

& 40mm

beams, but expensive

T-Slotted in sizes: 1", 1.5", 1x2", 20mm, 25mm, 30mm, 40mm,

45mm - many versions including curved to build up a circle.

Quick Frame (hollow square tubing): 1" + square tubing with

fins in various places ("P" & "A" tube) plus flanges.

Ready Tube (hollow square tubing w/drilled holes): 1", 1.5"

(use with Standard Tube Insert)

a ton of fasteners

- Panels

Doors - Floor

-Frame - Structrual

Shapes - Add-On

Components - Finishing

Trim - Tools - Kits (EF101

- $254.25) - Basics -

EF101

Qty

|

Size

|

Desc.

|

p/n

|

2

|

1x1x12"

|

T-Slot

|

1010

|

2

|

1x1x8"

|

T-Slot |

"

|

6

|

1x1x6"

|

T-Slot |

"

|

4

|

1x1x4"

|

T-Slot |

"

|

2

|

1x2x6"

|

T-Slot |

|

1

|

1x2x2

|

T-Slot |

1020

|

1

|

6.5x2.5

|

Panel

|

|

1

|

8.5x6.5

|

Panel

|

|

1

|

10.5x8.5

|

Panel

|

|

4

|

|

Roller Wheel

|

|

2

|

|

Drop-In T-nut

|

|

1

|

|

Brake Assy

|

|

2

|

|

But Fastener

|

|

1

|

90 deg |

Pivot

|

|

6

|

1/4" |

washer

|

|

10

|

|

1/4-20 Hex Nut

|

|

4

|

|

Lift-Off Hinge |

|

6

|

|

End Caps

|

|

4

|

|

Double Slide-in Econ

T-Nuts

|

|

16

|

|

Single Slide-In

Economy T-Nut |

|

1

|

|

3-hole corner bracket

|

|

4

|

|

Panel Mount brackets

|

|

4

|

|

2-hole flat plate

|

|

4

|

|

2-hole corner bracket

|

|

8

|

¼-20 x ¾” |

FBHSCS |

|

16

|

¼-20 x ½” |

BHSCS |

|

8

|

¼-20 x 3/8” |

BHSCS |

|

8

|

|

Anchor Fastener |

|

10

|

|

End Fastener |

|

1

|

7/16 |

Box End Wrench |

|

1

|

5/32 |

Hex Driver |

|

1

|

3/16 |

Hex Driver |

|

1

|

|

Assembly Guide |

|

1

|

|

Storage Case |

|

YouTube: Tech

Ingredients: @9:26

80/20 Products -

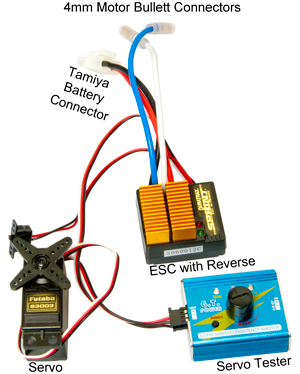

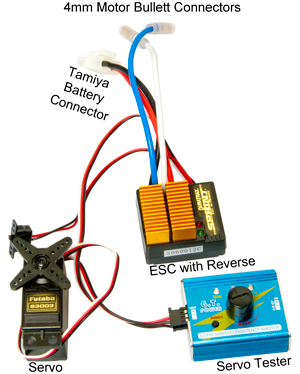

Electronic Speed Controls (ESC) &

Related Controls

Very small DC motors can be controlled using

transistors but larger motors run with much higher currents and

need high current H bridges.

The input to the ESC is typically the pulse width modulated

output from an Remote Control (RC) receiver, but some allow for

other input formats like serial bytes or packets.

Dimension

Engineering - Sabertooth

dual 25A motor driver - Kangaroo

X2 Motion Controller -

Pro-Bot

-BeeBot

- Logo

language bots

Duratrax - DTXM1200

Electronic Speed Controller (on order 11 July 2013)

G.T.Power RC Servo and ESC Tester

(AsiaTees Retail store selling G.T.

Power equipment) (on order 11 July 2013)

|

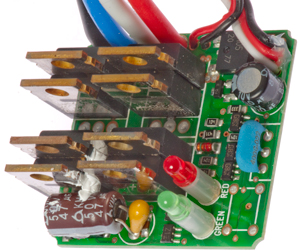

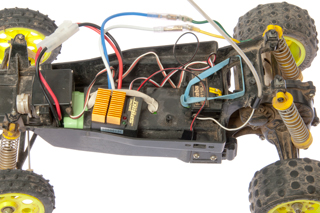

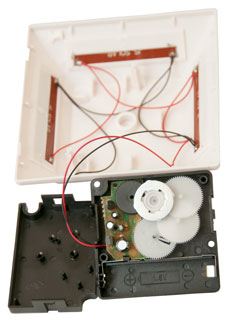

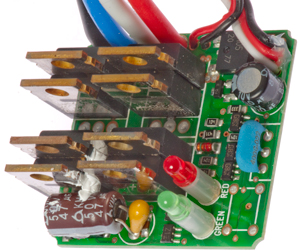

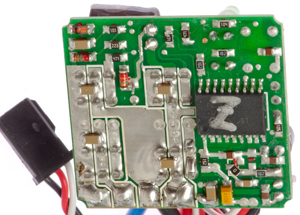

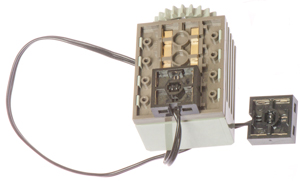

Duratrax Sprint 1 ESC w/Reverse opened

Top

Blue 4 MHz resonator at right for PIC, rectangular hole

pattern for switch? at lower right

IRFZ34N

HEXFET: 40 milliOhms, 29 Amps (4ea at top, left 2 in

parallel, right 2 in parallel)

IRL3103

HSXFET: 12 milliOhms, 64Amps (4ea at bottom, left 2 in

parallel, right 2 in parallel)

|

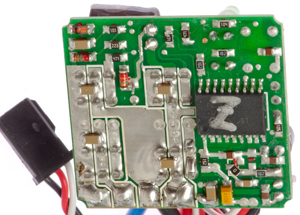

Duratrax Sprint 1 ESC w/Reverse opened

Bottom

Wire connections at bottom left to right:

Red Batt-, Blue Motor, White Motor (center big

trace), Black Batt-, red/black On/Off sw (BA05

regulator), blk/red/wht servo input

18-pin PIC micro controller

|

Video of the above setup

|

The tester has three modes:

1.Manual: turning the knob moves the servo and changes

the motor speed from full reverse - stop - full forward.

2.Neutral: the servo is in the center position and the

motor is stopped.

3.Sweep: the servo moves back and forth and the motor

cycles between full reverse, stop, full forward, stop,

etc.

The Electronic Speed Control (ESC) has a 5 VDC output on

it's servo cable that powers the tester, so no

additional power supply is needed.

That same method probably will power a RC receiver with

5 VDC derived from the 7.2 VDC main battery.

There is also an On/Off switch attached to the ESC which

would also power down the receiver.

In the early days of RC instead of the ESC they used a

high power wire wound pot driven by a servo.

|

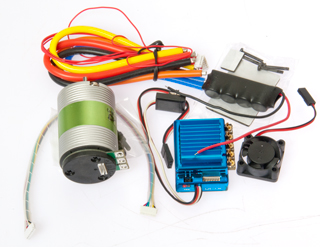

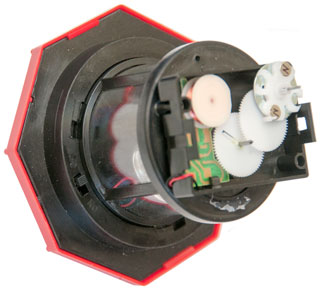

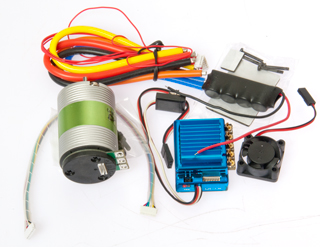

540-13.5T 3150 Kv Brushless DC Motor

& HW 120A Sensored ESC + misc supplies

The black stick with red & black wires is a

capacitor too big to fit into the ESC.

|

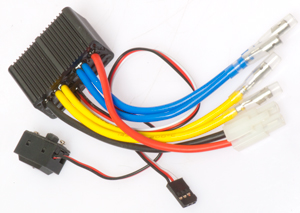

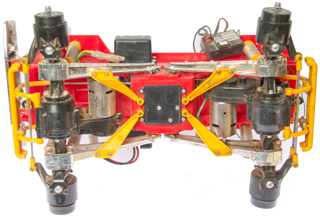

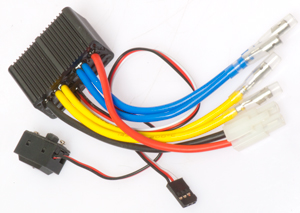

Dual Motor ESC for Tamiya

Bullhead Truck

|

Chassis

Lynxmotion - Aluminum 4WD1 Rover Kit

Arduino

Robot - Maker

Shed -

Torssen

Robotics - Arms & Legs

Lego

Lego has provisions for adding DC PM Motors and this

includes shafts, gears, etc.

This was later upgraded to include controllers and sensors.

Before Controllers there were Motors

Long before controllers there were many electric motors.

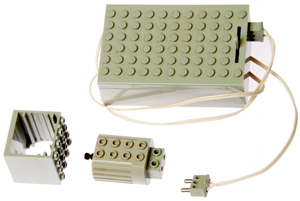

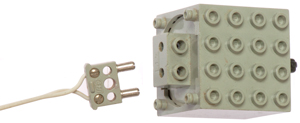

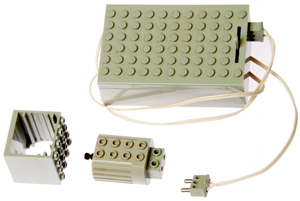

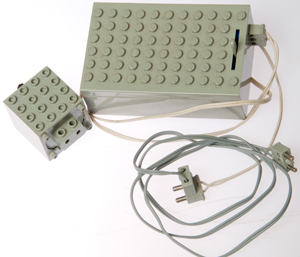

First Generation 3-C Cell Battery Box

& Motors

(connection cables missing)

Battery box accepts 2 or 3 prong electrical plug.

Battery Box may be x468 |

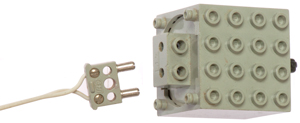

2-prong electrical plug connects to

battery box

and this motor. 8055 motor, different battery box

(the 8055 was a long 3 AA box).

Maybe 6216m

motor |

These motors have metal strips on bottom

and

do NOT accept either 2 or 3 prong plugs.

|

Note 3-hole plug and socket. 4.5

Volt system.

|

Note: 2-prong plug and socket, will also

fit 3-hole socket.

|

|

|

|

|

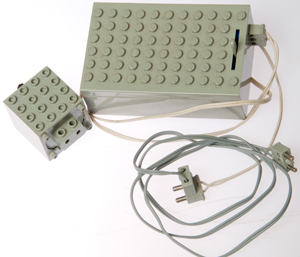

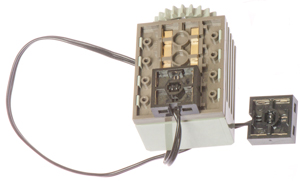

RCX

This was the first controller and used an 8 bit

microcontroller.

First LEGO Brick controller

MINDSTORMS®

SDK2.5

Official Lego

Mindstorms site no longer has RCX stuff

|

6 AA cells: 9 Volts

|

IR Tower used as link between computer

COM port and the brick

|

Sensor

|

This might be either 71427 or

43362? |

Lego brick with electrical connections,

uses bricks as electrical connection, not prongs.

The black LEGO electrical 2x2 blocks are for

RCX motors. (Wiki)

may be the 2838c01

9 Volt system

|

|

|

|

NXT

This is the next upgrade from the RCX controllers. A more

powerful uC and improved motors, sensors, etc.

The LEGO NXT series uses a (non standard)

6P6C modular connector. (Wiki)

The NXT mechanical system is different than the classic Lego

bumps.

The NXT motors are called "servo motors" because they contain a

sensor.

This is really a "sensored" motor in the parlance of the RC

world, whether it be a burshed or brushless motor.

NXT

schematics

Deriving power

from NXT® motor port A by Philo

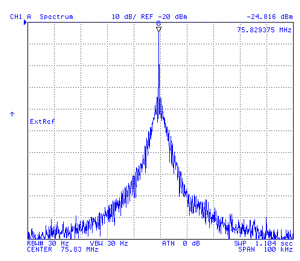

NXT "servo Motor" 53787

This is what the RC community would call a brushed

sensored gear head motor.

It contains two stages of planetary gears.

The top and bottom three hole groups are on the standard

8mm

Lego bump pitch. The "X" hole in the red motor

output is

standard Lego. The four holes on the red motor

output are NXT.

|

Offset notch 6P6C connector

|

|

|

|

|

Power Functions

This is different from NXT. Power Functions motors are

not part of the NXT system.

The GlideWheel

PF Motor controller by MindSensors.com allows

a NXT controller to operate Power Functions motors.

The Glide Wheel has the mechanical interface so it can be

connected to the drive face of a PF motor and it contains the

in phase and quadrature rotation sensor needed to make what

Lego calls a "servo motor". That's to say the Glide

Wheel when attached to a PF motor makes the motor appear to

the NXT system as a "servo motor". Note: you can

install the Glide Wheel on a motor or after some gearing (but

be sure that the direction of rotation is the same).

Power Functions™

presentation by Philo & Didier Enjary

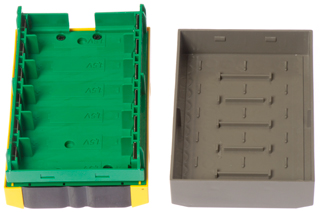

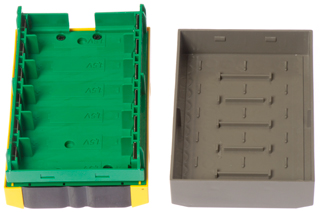

6-AA Battery box, Motors w/attached

cables

Gears, couplings, shafts, etc.

9 Volt system

The motor may be the 58120cx1 |

Lego 8882 motor

Note: 4 electrical connections (why?) not aligned with

brick bumps.

39mm dia x 48mm long

May have 2 stages of planetary gear reduction.

Note: No classical Lego bumps.

|

|

|

|

|

EV3

This is the next generation due to be released Fall 2013

Mindstorms

EV3 (Wiki)

Wheels & Tires

Lego has a standardized axle system that goes all the way

back to the first generation motors. I started looking

at Lego because they offer a lot of choices in wheels and

tires that can

be used for non Lego vehicles.

LEGO Bulk Lot of Wheels Axles Tires Rims

100 Pieces (on order 11 July 2013)

14mm dia x 9mm wide

NOTE: These wheel DO NOT accept standard LEGO

axles!

|

|

|

Lego Wheels and Tires Large 56 x 28 ZR *

NEW Dark Red (on order 11 July 2013)

|

|

|

Lego Gold Wheels & Balloon Tires 43.2

mm

9441 9444 70502 Ninjago Chima (on order 11 July 2013)

|

|

|

4 Lego NXT Technic Wheels TIRES RIMS 37 x 22 (on order

11 July 2013)

|

|

|

LEGO 24x43 wheel & tire (Lego

size width x radius?)

24mm wide x 82mm dia

Wheel:

24mm w x 43mm OD

|

|

|

Lego Wheel & Tire (Lego size? 11x21?)

11mm wide x 42mm dia.

Wheel:

7mm w x 17mm OD

|

|

|