When the telegraph system was just

getting going in the early 1800s electromagnets were one of the first

components. At that time they typically consisted of a pair of

coils wound on iron cores. These were used for Sounders and

relays early on. By connecting a pair of coils to an escapement

you could turn the type wheel in a stock ticker quotation machine or

turn the minute hand of a clock.

A pendulum clock would act as a master and drive a number of secondary

or slave clocks in public buildings or factories. The Standard

Electric Time Co. was one of a number that made this type of clock.

As received there are a couple of problems.

The spring that moves the minute hand is not strong enough. A

temporary fix is to add some 3"x5" card stock to put more tension on

the spring and this allows the clock to keep time. You can see

the spring in the photo at the left held down by the card stock.

The glass was not tight. It's held in place by a narrow ring of wood, but all the brads have fallen out.

The glass is held in a door that can be hinged up to set the hands

manually but only while the electromagnet's armature is manually

pressed to free the escapement. By using the smallest brads at

the local hardware store and placing them in the existing holes in the

wood (Bamboo?) ring the glass has been reattached. If the

existing holes were not there it would be necessary to drill new

clearance holes since driving a nail into this wood would surly split

it.

Coil Electrical Properties

Inductance 390 mH, Resistance 10 Ohms,

pull in current 260 ma, drop out current 30 ma. This is with a

small piece of 3x5 card stock adding tension to the spring.

Without adding tension the clock will not move the hands, but with the

card the clock keeps time and the pull in current is about 60 ma and

drop out current is 10 ma.

Coil Calculations

DC

Note that from Ohms Law 10 Ohms times 260 ma is 2.6 volts so you might

expect that clock to operate on a 3 volt power supply and it

will. But if you have a number of clocks all connected in series

then for each added clock another 3 volts will be needed.

Turn On Time

The time constant for a circuit with inductance and resistance is T = L

/ R, so for this clock that's .39 H / 10 Ohms = 0.039 seconods or about

40 ms. It takes about 3 to 5 time constants for the value to

settle so let's say it's in the 0.1 to 0.2 seconds area. Maybe a

little slow, but still much shorter than a minute. The turn on

time can be shortened by placing a resistor in series with the circuit (see

13 May 2007 below).

Turn Off Time with Snubber Diode

When

the current is stopped the coil generates a voltage spike that's

opposite in polarity from the polarity when the coil was powered.

A common way to protect a transistor that's driving a relay is to place

a diode across the coil with the diode back biased during normal drive

so that when the voltage spike happens it will be shorted out in the

diode. This same method will keep the points in a mechanical

clock from arcing.

This will slow down the time it takes to discharge the coil. The

time constant is the same as calculated above or about 0.1 to 0.2

seconds. So even when these are added toghther they are still

much less than a minute.

For applications like Teletype machines or

Stock Tickers where you need speed the snubber diode can not be used.

Series and Parallel Movements

There are two ways the slave clocks

could be connected, in a Series loop or in Parallel. A major

concern was a way to prevent arcing when the master clock opened the

circuit. This was typically done by a relay for each circuit and

a large building may have dozens of circuits and hundreds of clocks.

The Series connection allows each movement to be tuned then a shunt

resistor wound so as to bring the operating current into the 160 to 180

ma range. Then all the clocks in a circuit have the same current

and so operate reliably AND the shunt resistors act as snubbers to

prevent arcing of the relay points.

The Parallel connected movements don't have the resistor and are

supposed to work reliably from 22 volts (i.e. a 24 V circuit with some

wiring loss.)

Electro-magnets & Shunt Resistors

As current goes into an electro-magnet

it charges the magnetic field. If the current is stopped the magnetic

field collapses generating a current in the opposite polarity but

starting out at the same value. If there is no snubber circuit across

the coil the voltage can be very high. This causes arcing on the

mechanical points controlling the current input, wearing out the points.

By placing a resistor in parallel with the coil about five to ten times

the

coil resistance the voltage across the coil at the start of the back

EMF will be five to ten times the normal coil voltage and so eliminates

the

point arcing problem. The early shunt resistors were made in the

form of a

coil wound on a non magnetic core where the wire gauge and length

determined the resistance. Note the skinny coil in the above

photos that has it's long axis front to back. Newer versions use

a carbon composition

axial lead resistor.

At first look it appears that there are more more modern snubber

circuits than a plain resistor which dissipates power during coil

charging. For example spark ignition engines use a capacitor across

the distributor points. After the points have been closed for the

dwell time just before they open the capacitor is at zero volts. Just

after the points open the coil back EMF sees the capacitor at zero

volts and so can only generate a voltage across it's own internal

resistance (a very low voltage). Industrial relays use a snubber

circuit consisting of a resistor in series with a capacitor.

But looking further shows there's a second reason why the shunt

resistor was used. It's to prevent a whole string of series connected

clocks from failing if one clock has an open coil. The same idea as

cheap Christmas tree lights.

If this clock has a coil resistance of 110 ohms with a shunt resistor

of 11 ohms yields a combined resistance of 10 ohms. A 24 volt

circuit would have 8 clocks in series and a loop current of 24 V / 80

Ohms or 300 ma. If one coil opened the loop resistance would go

up by 100 ohms or to 180 Ohms and the loop current would fall to 133

ma. Which is still way above the 60 ma needed to operate the

electro-magnet.

Operation

IMP-2 Slave Clock Impulser

I plan to add a driver stage to my

Precision Clock so that it can drive secondary clocks. But in the mean time I got a

Piexx model

IMP-2 Slave Clock Impulser.

Note:

This Clock Impulser is designed to drive a string of up to 10

clocks. If you are driving only one clock you should place a

resistor in series so that the nominal voltage drop across one clock is

1/10 of the total loop voltage.

I choose the 4 "C" battery holder but they also offer other battery

sizes. This is a cleaver circuit that will drive a number of

different types of slave clocks. It has a built in LM 2733 boost

Switching Mode Power Supply that the micro controller can set for

either 12 or 24 volt outputs. The clock driver circuitry can be

wired for either Uni-polar (like for this clock) or for Bi-polar drive

like used in some European clocks. When the Uni-polar output is

being used for the clock the extra terminal that's not being used can

be connected to an electromagnet that will strike using one of

these:

- Hour Strike

- Hour & half hour strike

- Ships watch strike

- Westminster strike (requires optional board)

- <deactivated>

The rate of the clock can be speeded up or slowed down using the input keys.

To control the IMP-2 there are two input pushbuttons, Set and

Advance. Three status LEDs: Set, Mode and Advance as well as the

impulse LED which also acts as a status LED let you know where you are

in the menu as well as reading back the current vlaues.

In addition to the built in selections for clock type:

- Standard Electric, Stromberg (older)

- IBM (slow type), International

- Gents, other European

- Modern Stromberg

- Manual parameter setting of: Clock Pulse Width, 12 or 24 volt, #

pulses per minute, Uni or Bi Polar, speed up (0.1 sec/day), slow down

(0.1 sec/day), Set minutes for strike, set hour for strike, Chime

style, strike pulse width

- Brille

Experiments

13 May 2007 - The

calculations above based on the electrical measurements show that less

than 3 volts is needed to drive the clock, yet slave clocks of this

type are specified to run in a 24 volt circuit. The reason is

that one circuit can have up to 10 clocks. Remember that for each

battery added to a system there's both the added cost of the battery

and also the added cost of maintenance. So at the time I'm sure

someone worked out a minimal cost number of batteries and it came out

to provide 24 volts. At any rate the clock was designed to be one

of 10 in the loop, so when you drive just one clock in a 24 volt loop a

resistor can be added to make up for the other 9 clocks. 9 clocks

* 24 volts / 10 clocks = 21.6 volts that needs to be dropped.

21.6 volts / 260 ma = 83 Ohms. I used 100 ohms and it's

working. Not only is the clock much quieter but the tick is much

crisper sounding. That's consistent with the faster response time.

14 May 07 - 100 Ohms was too high. The clock was not advancing on

every pulse. Tried 47 ohms and it too may be too high this

morning the clock was 30 minutes slow which probably means missing

pulses. The friction is probably too high at the hub where the

minute hand is a rod inside a sleeve. I've read not to use oil

because it gets gummy in time, but maybe one of the new synthetic oils

would work here? But the minute hand now points smartly to the

line on the dial without the prior slop.

Have used a tiny amount of charcoal lighter fluid wicked between the

minute shaft and the hour sleeve to clean that joint. Now the

minute hand will spin like a top, which it would not before.

I haven't yet received all the literature for this clock. It may

be that I need to disconnect the shunt resistor to allow for more

efficient operation and that's probably quieter and more precise

operation.

19 May 07 - Still something wrong. The minute hand is not

advancing on every pulse. The electromagnet is lifting the pawl,

but it doesn't always move the minute hand. Try increasing the

thickness of 3x5 card stock on the lever spring wire.

25 May 07 - the "Operation and Adjustment of Non-Resetting Minute

Impulse Secondary Clocks (Series or Parallel)" arrived today. And

after going thought the four steps the clock appears to be working, but

I'll know tomorrow. Now it's the one telling the correct time in

the

3 Clocks Photo.

31 May 07 - at 1:08:14 actual time the IMP2 pulsed the SETSC to 1:0:00

pm. So in about 6 days the IMP2 gained 1 min 46 sec or 106

seconds or 17 sec/day. Got lost in the IMP2 menu system.

31 May 07 - 6:00 pm crancked in 7 seconds per day retardation and restarted.

Adjustments

Based on the SET publication "Operation

and Adjustment of Non Resetting Minute

Impulse Secondary Clocks (Series or Parallel)" dated March 1, 1968,

TI-1179 Attn: All Salesmen and Field Service Personnel Available

from

Jeffrey Wood.

1 Adjust or add the Drive Pawl spring.

2 Back Pawl adjustment

3 Drive Pawl Adjustment

4 Drive Lever Spring Tension

After going through the above steps in order the clock is working fine.

Minute Hand

The minute hand is not fixed to the

minute shaft, but is coupled by a clutch (see the patent

above). At first I thought the reason for the clutch was to

allow adjusting the minute hand over a distance less than 1 minute so

that it points to one of the minute dial marks. But now see that

it allows the minute hand to be set anywhere in the hour simply be

lifting the glass and moving the hand manually. When this is done

the hour hand follows the movement of the minute hand. Remember

that the minute shaft is the start of the gear train and is driven by

the electromagnet and locked by the two pawls. When the minute

hand is moved it's connected to the gear that drives the hour hand.

The

minute hand is balanced. The short end has a circular weight

attached by a rivet. In the photo you can see the jeweler's

screwdriver balanced on the tweezers and the minute hand balanced on

the blade of the screwdriver. In the background are the washer

with square center hole and the pin used to hold the minute hand on

it's shaft. Also on the right is the square wood clock box and on

the left the round door since the clock is on it's side.

The slop caused by the location of the two pawls can be minimized by

rotating the fixed pawl stop support arm. But after doing that

I've found that there's additional slop between the minute hand the the

square shaft where they are joined. This was fixed using an

automatic center punch on the back side of the minute hand where it

will not show. The front side was on a hard surface. This

worked the metal a little and closed the gap.

Performance Metrics

1. Position slop of the

minute hand. This clock has slop in the minute hand that's 1 full

minute wide. That's to say you can move the minute hand back and

forth and it covers 1 minute of time. That's way too

sloppy. The movement should be say 10% or less of a minute.

I'm waiting for the instructions before bending the fixed support pawl

arm to tighten up the movement.

2. Power needed to move hands. There now is a

resistor (looks like a coil) that shunts the working coils they wasting

power. This could be disconnected for single clock use. The

shunt resistor is a first generation snubber that absorbes the back EMF

when the coil drive current stops. Without the shunt resistor the

points in the master clock arc and destroy themselves in short order.

3. Pointing accuracy of minute hand. After the slop

is removed the minute hand should point to one of the minute marks on

the dial, not between the marks.

4. Stepping Speed. To determine the minimum power

needed to move the hands the drive current and/or pulse width is

reduced and the clock watched to see if it misses a beat. This

can take a very long time so by running the clock at much higher speeds

the test time can be shortened.

Patents

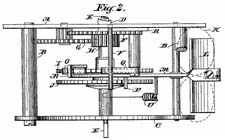

The key feature of the SET clocks is

the two wheel escapement as set forth in patent 363440. One of

the problems of other escapements is that when there's nearby lighting

the clock minute hand moves due to the induced current spike. The

SET design does not move.

Later patents added hourly setting of both the minute and hour hands

using a number of different methods. The earlier methods were

noisy during the setting process and later methods not so noisy.

The movements that have the hourly setting look very similar to the

above except have a second coil on the left making a "V" arrangement of

coils.

363440 Secondary Electric-Clock Movement, Charles D. Warner, May 24, 1877, 368/59 ; 74/156

- The patent shows item "U" a short fast acting coil spring to

pull down the armature arm, but the actual clock uses a wire spring.

- The patent shows holes "T" near the base of the radius arm base where

it mounts to the back of the dial plate to facilitate rotating the

radius arm about it's single rivet base to adjust the slop in the

minute hand, but the actual clock does not have those holes.

- Patent line numbers 52 to 58 point out how easy it is to make the stop

pawl adjustment by rotating the radius ram about is rivet. Lines

58 to 63 point out that the stop wheel is "movably mounted" to the main

shaft so that it can be adjusted. These two adjustments allow

both minimizing the minute hand slop and getting it to point on an

exact minute boundary dial mark. Although not marked in Fig 2 the

clutch disk that movably holds the stop wheel "J" on the minute hand

shaft "E" is shown.

- "N" on the armature is described as an adjusting screw, but it's purpose is not mentioned.

387703 Circuit-Closer for Electric Clocks,

387704 Electric Clock System, Charles D. Warner &

Arthur D. Bennett (Standard Electric Time Co), August 14, 1888, 368/52

Links

Back to Brooke's Time & Frequency, Personal Home, PRC68 Home

[an error occurred while processing this directive] page created 30 April 2007

When

the current is stopped the coil generates a voltage spike that's

opposite in polarity from the polarity when the coil was powered.

A common way to protect a transistor that's driving a relay is to place

a diode across the coil with the diode back biased during normal drive

so that when the voltage spike happens it will be shorted out in the

diode. This same method will keep the points in a mechanical

clock from arcing.

When

the current is stopped the coil generates a voltage spike that's

opposite in polarity from the polarity when the coil was powered.

A common way to protect a transistor that's driving a relay is to place

a diode across the coil with the diode back biased during normal drive

so that when the voltage spike happens it will be shorted out in the

diode. This same method will keep the points in a mechanical

clock from arcing. I plan to add a driver stage to my Precision Clock so that it can drive secondary clocks. But in the mean time I got a Piexx model IMP-2 Slave Clock Impulser.

I plan to add a driver stage to my Precision Clock so that it can drive secondary clocks. But in the mean time I got a Piexx model IMP-2 Slave Clock Impulser. The

minute hand is balanced. The short end has a circular weight

attached by a rivet. In the photo you can see the jeweler's

screwdriver balanced on the tweezers and the minute hand balanced on

the blade of the screwdriver. In the background are the washer

with square center hole and the pin used to hold the minute hand on

it's shaft. Also on the right is the square wood clock box and on

the left the round door since the clock is on it's side.

The

minute hand is balanced. The short end has a circular weight

attached by a rivet. In the photo you can see the jeweler's

screwdriver balanced on the tweezers and the minute hand balanced on

the blade of the screwdriver. In the background are the washer

with square center hole and the pin used to hold the minute hand on

it's shaft. Also on the right is the square wood clock box and on

the left the round door since the clock is on it's side.