Battery Testers

© Brooke Clarke 2007 - 2022

Background

State Of Charge

Radio Shack 22-080 Household

Battery Tester

ZTS Mini-MBT

ZTS MBT-1

TS-183 Mil Dry Battery Tester

PSM-13 belt carry Mil Radio

Battery Tester

TS-4403 LiSO4 Mil Radio

Battery Tester

TS-23 BA-1574/U Mercury

battery Tester

Drop Test

Capacity Testing

Coulomb Counting

Resistor

Filament Flashlight

Bulb

Constant Current

Constant Power

Electronic Load

Watt's Up

Maha 777Plus

Maha MH-C9000

Triton2

iMAX B6 LCD Screen

Digital Lipo NiMh Battery Balance Charger

1.5v~12v

Battery Capacity Meter discharge Tester 3.7v 18650 lithium

lead-acid

BF-1L Battery Fixture (Single

Cell)

Foxwell BT-705 Battery Load

Tester (see Brooke's Vehicles web page)

Internal Resistance

Examples

EVB ESR/Low Ohms Meter

HP 4328A Milliohm Meter

ESR-Cap meter

SM8124 Battery Impedance Meter

SM8124A

Battery Impedance Meter

Dynamic

Resistance

Shelf Life

Analyzers

Cadex C7200

Flash Amps

Links

Background

There are a number of reasons why

you might want to test the capacity of a battery. For

household type batteries it's good to know if it's the battery

that has died or the device holding the battery. When

working with rechargeable batteries it's good to know the state of

charge, i.e. what's the capacity.

I've found a number of cases lately where the Radio Shack battery

tester shows in the middle of the green, yet the battery is not

powering the device.

State of Charge

These testers estimate the remaining

life of a battery. For Carbon Zinc and to a lesser extent

Alkaline this can be done by measuring the battery voltage while a

light load is applied. If the proper load is chosen for a

given battery capacity the loaded battery voltage works well as an

indicator of remaining life. The idea is to determine the

state of charge using as little of the batteries capacity as

possible.

HP 66311A Mobil Communications DC

Source

This test instrument was specifically designed to measure the

power consumed by battery operated devices, like cell phones,

and to measure the associated battery and battery charger.

Radio Shack 22-080 Hand Held

Battery Tester

Aug 2007 -

Added

test jack table to

TS-183 web page so that the Radio Shack load resistors could be

compared to the TS-183 load resistors. The Radio Shack

tester showed a 9 volt battery as good yet the battery would not

work in the Stamps.com postal scale. The TS-183B showed the

resistor as bad after abut 5 to 10 seconds. There's a 100%

difference in the load resistors for this voltage. Need to

check the others.

In addition to the test leads this battery tester also has metal

contacts for a 9 volt battery on the front panel, the negative

contact and be used on the bottom of AA, C, D battery and the red

lead to make testing easier. On the right side is a slot for

button cells and part of the front panel can be depressed to make

contact to them. For most common batteries I have used this

tester, but now am no longer as confident in it's abilities.

| Range |

RS

Load R

|

Yellow

V

|

FS

V

|

TS-183

Load R

|

1.5v 1 ma

button cell

|

1k7

|

1.13

|

2

|

|

3v 1m

Lithium cell

|

3k4

|

2.27

|

4

|

|

AAA &

N 50 ma

|

30

|

1

|

1.6

|

|

AA

& C & D 150 ma

|

10

|

1

|

1.6

|

6

|

Photo 6v

|

600

|

4

|

6

|

|

9 volt

|

900

|

6

|

9

|

544

|

| 12v |

1k2

|

8.3

|

12

|

|

| 15v |

1k5

|

10

|

15

|

|

| 22.5v |

2k3

|

15.5

|

22.5

|

|

ZTS

Mini-MBT

Since the above Radio Shack tester does not

work very well I've been on the lookout for an improved

tester. ZTS makes a number of handheld battery testers and

the Mini-MBT (Multiple Battery Tester) is what got. They

have a utility and a design patent.

6823274

Apparatus and method for testing remaining capacity of a battery,

Nov 23, 2004, ZTS,

702/63 ; 320/125; 320/136; 702/64;

702/65; 702/79

uses voltage at end of resistor load

pulse.

D515444

Battery Tester - packaging for the 6823274.

When a battery is connected it's immediately under load and after

a few seconds the loaded voltage is read. The capacity is

based on the loaded voltage at the end of the test

time. The patent has data on the load resistance for 8

different battery types as well as capacity information in 20%

steps for 3 & 6 Volt versions of the CR123 photo battery and

for the 1.5 volt alkaline terminal.

The four battery types that the MBT will test are:

Cell Type

|

Details

|

Ni-MH

|

1.2

volt

|

Alkaline

|

AA,

AAA, C, D, N

|

Lithium

|

CR123,

CR2, CRV3

|

Alkaline

|

9V

|

I checked the same battery that the Radio Shack tester showed in

the green and this tester either shows it as bad or on the second

try it failed to start the test, meaning it's dead.

Also checked some CR123 cells that have been here for years.

They test at different levels. I haven't made any controlled

discharge tests to see how accurate this tester is, but at a first

look I like it.

The Mini tester uses a

socketed 18 pin micro controller without a seperate MUX IC and

without an external crystal. The circuit board is soldered

to the positive and negative battery terminals and so can not

easily be removed. There's a 4 post 0.1" header for testing

the unit, but it's between the PCB and back cover so is not

accessible after the front cover is removed.

Instead of using a switch like on the Radio Shack tester, this one

uses 4 different positive battery terminals and a common negative

test lead. There's a groove around the tester to hold the

lead and a pocket for the short probe body on the left side not

shown in the photo. The On button is on the right side.

There are two lower priced ($30) models this one (Mini-MBT) and

the MINI-MBT9R. The difference is that on this one the lower

left terminal is for the CR123 Li-MnO2 primary battery and on the

other one it's for a Rechargeable 9 volt battery. I

specifically wanted to try the CR123 battery test since I use

these in some of my products (

5BA,

90BA Battery Adapters).

The

TS-183 works the same way.

You pick the test jack to match the battery instead of using

switches. The load is permanently associated with the

jacks. For example on the TS-183 jacks 1, 2, 3, & 4 are

for single cell batteries and 1.40 V is the 80%

indicator. Jack 3 is for a "D" Zinc Carbon battery and

uses a 6 Ohm load. The ZTS tester is using a 9.1 Ohm for

alkaline cells with a 80% voltage of 1.41 V. ZTS could

eliminate the whole relay circuit and thus lower the cost of the

tester since one of the connections to the cell under test is by

the probe. That's to say whoever is testing the battery has

to hold the probe on the cell If there was a socket

holding the cell then the relay has some merit, but in this case

it's not likely someone will "forget" and keep holding the probe

on the cell for an extra hour or more.

There are some aspects that could be improved.

- Using a post for the battery positive terminal seems to be

upside down. Either use a socket for the positive

terminal or make the post for a negative terminal. It's

not as bad as balancing a pin on the point of another pin, but

not that far different.

- The display is at the top so when you are holding a battery

upside-down on one of the posts with one hand and holding the

probe with your other hand the display is somewhere behind

your hands. Better to place the display at the

bottom. If you turn the unit upside down then the

display reads backwards and the labels are all upside down,

and you need to be left handed, but it still a better way to

use the stock tester.

- The On button seems to get activated whenever the unit is

handled. Maybe put it on the top narrow face where you

don't normally hold the tester.

- The word Pulse" does not seem to have anything to do with

how it works. The load resistor is always connected to

the test terminal so the battery sees the load as soon as the

circuit is compleated. When powered up the tester scans

all the terminals and when it finds on with a voltage starts a

timer. At the end of the time (always 3 seconds?) it

reads the loaded battery voltage. So there's no pulse

involved. Then, after making the measurement the relay

opens the load resistor to keep from draining the

battery. Maybe this is what they mean by pulse?

These are nit picks. This is be far the best battery tester

I have.

They make more expensive testers

that can test a longer list of batteries.

ZTS MBT-1

U.S. Patent 6823274 shows on the

front panel.

Runs on 4 AA batteries.

3.6 V Lithium-Ion

RCR123A

18500

17650

18650

|

1.5V Button Cell

S76

A76

A625

A640

|

1.2 V NiMH

AA

AAA

C

D

|

1.5 V AA Lithium

LS91

|

3V Lithium Button

CR2016

CR2025

CR2032

CR2320

CR2450

CR1/3N

|

6 V 28 Series

28A

S28

28L

|

3V Lithium

CR123

CR2

CRV3

|

1.5 V Alkaline

AA

AAA

C

D

N

|

12 V Alkaline

A23

|

9 Volt Alkaline

|

Army dry battery tester. Works

by measuring loaded voltage.

The set can be carried on a belt and

tests radio batteries, Vietnam era. Uses high current load

to activate Magnesium batteries.

4725784

Method and apparatus for determining the

state-of-charge of batteries particularly Lithium batteries, Feb

16,

1988,

324/427 ; 320/149; 320/150; 320/162; 340/636.15

Uses pulse loading and voltages

measured at various times in relation to the load pulse as well as

temperature correction. Capacity depends on manufacturer as

well as model.

Tests the BA-1574/U Mercury

battery used in the

SDU-5/E Emergency

Survival Strobe Light and the flash rate of the strobe.

BT-2 - Tests BA-1568/U as used in the PRC-90 Survival Beacon

Radio and others, BA-1113/U used on the URC-64 Survival Radio,

the K308A battery used on the

RT-10

Survival Radio, and the BA-1574/U used on the

SDU-5/E Emergency Survival Strobe

Light.

Drop Test

The idea is to drop a AA battery with the + end up on

a reasonable hard surface.

This may work for other Alkaline cells?

A good battery will make a thud sound, no bounces and may stand

up.

A bad battery will sound metallic, bounce and fall over.

How To

Test a AA battery, Easiest Way For Any Battery Fast, Easy!

The comment about testing with a volt meter is wrong. A

no load test does not mean anything.

For a meter test to mean something the battery needs to be

loaded. See the TS-183.

Even load testing does not work well on modern batteries.

Capacity Testing

The idea here is to drain the

battery using a known load until it's voltage is down to the end

voltage and record the delivered Amp hours, or better delivered

Watt hours. Note that when the battery starts the test it's

voltage is highere than at the end where the voltage is the pre

assigned ending voltage. So the early amp hours are at a

higher voltage than the ending amp hours. The early Watt

hours are higher than the ending Watt hours. So reporting

the run time using a load resistor or constant current source is

not as accurate as reporting the delivered Watt hours.

The results for a given battery will be different as a function of

the load.

Coulomb Counting

By measuring the current and the elapsed time the product of

them is how many coulombs (Wiki) have

flowed. Most modern rechargeable batteries use coulomb

counting to determine State of Charge and that can be translated

into remaining run time.

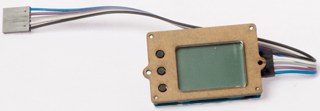

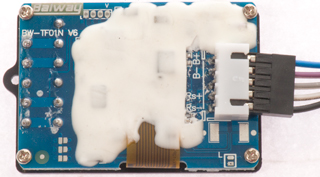

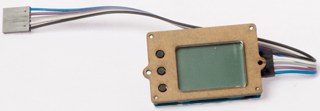

Baiway BW-TF01N Ver 6

Fig 1

|

Fig 2

|

This is a stand alone coulomb counting circuit available on

eBay lu_cytime208

with a title of "Capacity Tester Indicator for 0V-30V Lithium

LiPo / LiIon Battery LCD Display" for about $30.

It can be connected into either a discharge circuit to measure

battery output or into a charging circuit to see how much charge

in put into the battery. Note that you always put more

charge into a battery than you can extract. That's to say

the efficiency is always less than 100%.

This unit has no provision to turn the load on or off. It

is not a load tester nor is it a charger. The Set Voff

voltage is used to control when the TF01N goes into sleep

mode. The idea is to build this coulomb counter into a

battery pack so it's state of charge can be monitored and to

minimize the power used by the TF10N. There is an internal

current shunt that can be used for currents up to 3 Amps and

after that an external shunt can be used up to 50 Amps.

It has no provision for an external power source, but rather

runs on the battery pack it's connected to and that pack needs

to have a voltage of more than 8 volts (up to 50 Volts).

Resistor

A fixed resistor is the load. The load current decreases as

the battery voltage goes down.

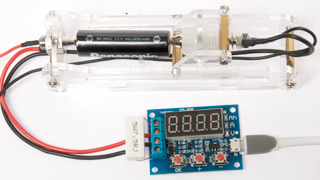

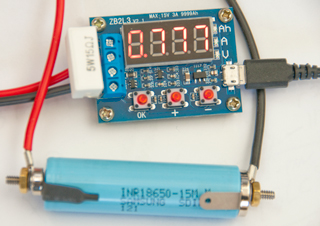

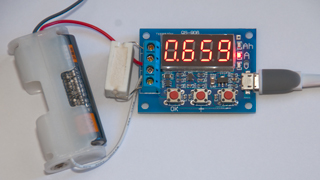

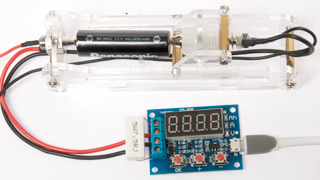

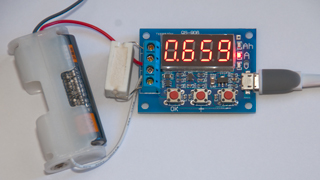

QS-906 eBay title: .5v~12v

Battery Capacity Meter discharge Tester 3.7v 18650 lithium

lead-acid

14 Sep 2016

This unit came from the same eBay seller as the first

non functional one,

but this one has a resistor marked R020

instead of a resistor marked R200 like the first

(improperly assembled) unit.

See below for battery fixture.

|

Discharging an eneloop.

More later .. . .

2.65 AH vs. label capacity of 2.45 AH.

roughly works without calibrating.

|

Fig 5

|

Testing 18650 battery:

15 Ohm 5W resistor (4.1v / 15 Ohm = 273 mA) close to the

300 mA spec

for this Li-Ion battery rated at 1500 mAh,

which tests between 1450 & 1470 mAh (0.777 mAh

shown)

K&J Magnetics parts to make connection to battery

use 6-32 flat head screws.

0.625" dia (RA22CS-P)

and 0.25" dia (R422CS-P)

|

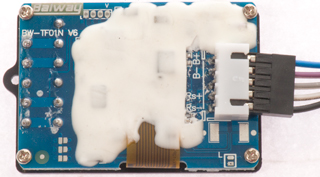

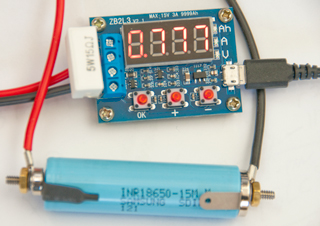

This is also known as a ZB2L3 ZHIYU Battery Capacity Tester

External Load Discharge Capacity Test (I have one of these on

order 29 AUG 2016)

The current sense resistor can clearly be seen with matching

markings on the PCB and resistor of R020.

Function

This is a battery capacity tester that uses an external

resistor as the load to drain the battery. The load

resistor has nothing to do with the device calibration.

Once properly calibrated the load resistor can be changed and

the readings will still be correct.

Load Resistors

The load should never exceed 20 Volts or 6 Amps because of the

MOSFET switch. The MOSFETs are in parallel so the current can be

higher, but I doubt as high as 12 Amps.

There may be a firmware limit of 15 Volts or 3.1 Amps.

The current through the resistor will vary from a maximum value

set by the fully charged battery voltage and resistance.

For example an eneloop AA battery may start out at 1.4 Volts

with a 7.5 Ohm resistor for a current of 0.187 Amps.

The power dissipated in the resistor is V * I or 1.4 V * 0.187 A

= 0.261 Watts.

Since the supplied resistor is rated for 5 Watts this is no

problem, but for more powerful batteries a resistor with a

higher power rating may be required.

Circuit Description

The tester uses a micro controller mounted under the 4-digit

7-Segment LED display.

An 8205s (pdf)

Dual MOSFET each FET speced: 28 mOhms RDSon with a max

rating of 20V or 6 Amps are connected in parallel and switch the

load to battery positive (see Fig 2).

The battery current is sensed by R2 (0.2 Ohms) between the

negative battery terminal and ground.

The battery voltage is sensed by (a guess - hidden circuit under

display) a voltage divider R3 & R4.

Just above the Ah LED is a 0.1" pitch 4-hole pattern that's

probably for in circuit programming of the uC.

The LM1117 (TI)

Low Dropout voltage regulator is set for a nominal 3.3 Volt

output (3.29 actual).

The uC is hidden so don't know make or model.

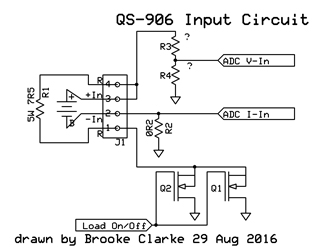

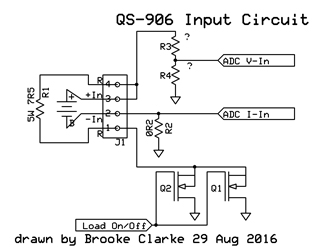

Fig 2 Input Schematic

|

Internal connection between R (J1-4)and +In (J1-3).

Guessing at R3, R4 Voltage divider.

R2 is the battery current sense resistor.

Q1 & Q2 in parallel to switch load to ground.

For all the parts except R2 the marking on the part

matches the nomenclature.

But for R2 the PCB is marked: R020

and the part is marked: R200

Photo

here shows a resistor marked R020.

|

Calibration

Battery and Resistor disconnected.

Step 1.

Display shows: 0A0u (zero Amps and zero Volts), Q1 & Q2 are

open so there is no load on the battery. The battery

voltage drives the microcontroller ADC.

Battery removed and either left open or shorted. Which

works best is TBD

When OK is pressed the zero calibration for both battery voltage

and current is stored (but not saved)

Step 2.

Display shows: 100u (10.0 Volts). Q1 & Q2 are open so no

load on battery or heat in resistor.

Remove battery.

External 10.0 Volt power supply to battery +In and -In

terminals.

When OK is pressed the voltage at ADC V-In is measured and a

ratio stored to get to 10 Volts.

Step 3.

Display shows: 200A (2.00 Amps). Q1 and Q2 are turned on. So if

resistor installed it will heat because of the internal

connection between R (J1-4) and+In (J1-3). But the

resistor can be removed during calibration to avoid overheating

it.

Remove battery.

Connect positive source of 2.00 Amps to -In (J1-2 in Fig 2 above) and the ground to J1-1 (bottom

R).

When OK is pressed the voltage drop across R2 is measured and

stored.

Note the circuit impedance is a few tenths of an Ohm so the

current source does not need to have a high voltage compliance,

like was needed if you mistakenly try to calibrate using the

battery terminals for this step.

Step 4.

When OK is pressed the above values are checked for

reasonableness (how is a mystery) and if they seem OK they are

saved in EEPROM in the uC.

Note this cal only needs to be done one time.

Operation

With the load resistor and battery connected power up the

QS-906.

Press (+) or (-) to see the termination voltage and then press

(+) and/or (-) to set the termination voltage.

Then press OK to start the test.

The first Ah display should be zero.

The first A display should be the battery starting voltage

divided by the load resistor value.

The first V display should be the battery fully charged

voltage minus a little for the effect of the load because of internal resistance.

Error Codes

Err1: the battery voltage higher than 15V

Err2: the battery voltage is lower than the termination voltage

setting.

Err3: the battery is unable to support the load current or of

the test lead resistance is too large.

Err4: the current is too large (current is more than 3.1A.

Example (29 Aug 2016)

eneloop AA cell after calibration using short in step 1 as

above. Results before test finished:

Ah: 3.076 [ended at 7.761 a little more than 3X the actual

value]

A: 0.665 (current still reads 4.01 x too high)

V: 1.24 (DMM: 1.277 V, implies a

current of 1.277 / (7.5 + 0.2) = 0.1658 A

Still not reading correctly. Maybe because of the R2 value

problem (PCB: R020, resistor R200).

Hacking

A way to fix the current calibration is to change the current

used for the cal and tweaking the value to get the current to

read correctly.

I'd like to use this to test BB-2590 military batteries that

are 4 cell Li-Ion, i.e. fully charged at 16.8 Volts, so a bit

above the 15 V firmware limit.

So . . . . by cheating on the voltage calibration by say 17 V

/ 15 V and after finding the correct current for a normal cal

change that by 15V / 17V.

This would require modifying the cutoff voltage by 17/15, but

then the Ah would read correct.

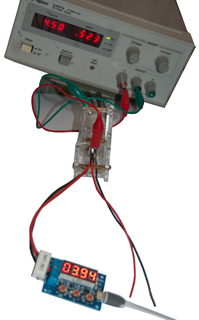

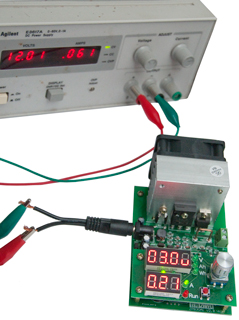

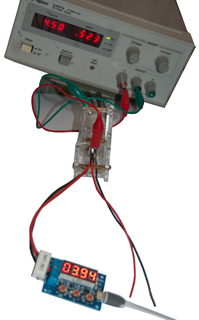

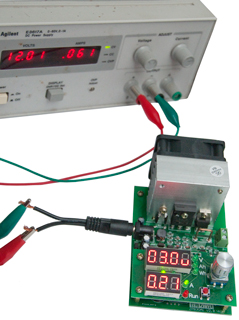

Fig 3 Checking Current

Power Supply on + & - battery terminals

Note PS= 4.50 V, measure 3.94 V because

of resistance of test leads.

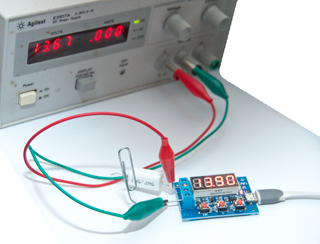

|

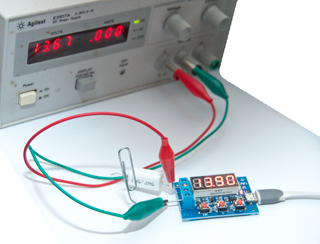

Fig 4 Checking Voltage

Load resistor disconnected.

PS on + and - battery terminals.

PS= 13.76 Volts (just under err1 voltage), measure=

13.98 V.

Note: err1 only happens when tester in run mode.

In startup mode I increased input to 18 Volts and the

tester

displayed it without any error message.

|

|

|

29 Aug 2016 resolved Prior Problems -

only read for background

Under $5 including shipping from Hong Kong. It

does NOT work as it should, needs updated firmware.

Fig 1 After OAOu:Short, 100u:10V, 200A:2A Cal

actual current is 1.37V/7.5Ohm = 0.182A, Display

current is 0.659Amp, Why?

Operation

An external 5W 7.5 Ohm resistor is switched to the

battery when the OK button is pressed and switched off

when the battery voltage drops below the limit voltage

indicated by Pnnnn.

But

After the battery is connected press + or - to change

the value of P and when correct press OK to start the

test.

YouTube video of QS-906

circuit running.

Maybe calibrated for Voltage (10V ref) and Current (2A

ref) So the tester can calculate the current given

the loaded voltage. If the test leads have too

much resistance:

Err3: the battery is unable to withstand the load

discharge current resistance is too large or line.

I have not yet figured out why some of the error

codes appear or how to do the Calibration. If

you know more contact

me.

The tester has NOT been calibrated and the default

cal is way off.

When testing a Panasonic eneloop pro AA battery with

the 7.5 Ohm load resistor the tester shows: 1.69 A at

1.28 V equivalent to a resistance of 0.757 Ohm

load. So way out of cal.

But when the same battery (fully charged) reads 1.409

V open circuit and 1.403 V with the 7.5 Ohm load

applied. Actual current is V / R = 1.403 / 7.5 =

0.187 A = 187 mA

The battery internal resistance is (1.409 - 1.403) /

187 mA = 0.032 Ohms.

Short current current might be = 1.403 / 0.031 = 43

Amps (but not likely).

Tried cal (holding down all 3 buttons then connecting

power. After start up displays: ---- (indicator

for Calibration mode), 0.004 (maybe offset voltage) ,

OAOu (maybe zero Amps & zero Volts)

when OK is pressed the display changes to: 10.0u when

OK pressed again display is 200A, and when OK pressed

again reverts back to Ah -> A -> V -> Ah

cycle. Doing the cal requires a power supply

that can deliver both 10.00 Volts and 2.00 Amps.

But after trying to do the cal first with 10V and 1A

and twice trying 10V and 2A the cal fails, i.e. when

testing the eneloop shows 1.8 Amps, way too high.

Also tried with current in negative direction, but

still get 1.8 Amps on the eneloop, not the 0.187A is

should be. Maybe some factor of 10 error?

Note: with the supplied 5W 7.5Ohm resistor when the

input is 10 Volts the power in the resistor is 13.3

Watts, and when 2.0 Amps are flowing the voltage drop

across the resistor is 15.0 (the max rated input

voltage) and the power in the resistor is 30 Watts.

This means the calibration must be done very quickly.

Maybe the Ah display is showing 10X the actual

capacity. Will test an eneloop to completion to

see if it comes our near 2.4 Ah X10 = 24 Ah.

The QS-906 shows 1.36 Volts and the DMM reads 1.348

Volts on the screw terminals. Shows 1.741 Amps

Voltage drop across the 7.45 Ohm resistor is 1.308 for

a current of 1.308 / 7.5 = 0.174 Amps

Note current is reading 10.0057 X higher than actual,

so it looks like a 10x error.

Next to see how the battery capacity compares with the

MH-C9000

(tested at 1.0 Amp load, but can be rerun at

something closer to 0.174A.)

If 2.4 Ah capacity and 0.174A load then 13.8

Hours to discharge. About 12:30 now.

About 1:00, was not watching, the mode indicator LED

is flashing for Ah, A and V instead on being on

steady. Displays: 1.003 Ah, 1.692A (actually

0.1692A) and 1.31 V (cutoff set to 1.20 Volts).

Do not understand whey flashing. Will let run

longer to see if V display (and DMM) go down to 1.2

V. Load resistor has 1.264V voltage drop (

0.168A) so still connected.

At about 11:00 pm the voltage was 1.24 V so not

done. Next morning very fast flashing and the

capacity shows at 19.71 Ah. Pressing OK twice

shows the voltage as 1.26, i.e. the cell has recovered

a little. Pressing OK some more times to restart

testing shows: 0.000 Ah, 1.583 A & 1.23 V.

So, it looks like the reported capacity might be 10x

the actual capacity. Now testing an eneloop at

200mA discharge to see what capacity it has.eneloop

has 2480 mAh capacity when discharged at 200 mA, so

the19.71 Ah (divided by 10 = 1.97 Ah is still way off.

Tried calibration:

1. Short, 0A0u -> OK

2. 10 V, 100u -> OK

3. 2 Amps, 200A -> OK

but when fresh eneloop battery installed the displayed

current is 0.669 Amps, much higher than the actual .174

Amps (384 % off).

The next day the display shows:

Ah: 7.125 (clearly much higher than 2.4 the actual

capacity)

V: 1.26 |

Filament Flashlight Bulb

The resistance of the bulb changes in a non linear way with the

battery voltage. The bulb gets dimmer as the battery voltage

gets lower. How dim does the bulb need to get to say the

battery is dead? Kind of a fuzzy feely thing maybe not the

best capacity test method.

Constant Current

When a constant current load is used the delivered Watt hours are

directly proportional to run time. This is the most constant

load type.

Constant Power

Switching Mode Power Supplies, like used in most modern battery

powered devices consume what's pretty close to a constant power in

Watts. This means at higher battery voltages they draw

smaller currents than when fed lower battery voltages. This

is the oppsite of the resistor load.

Electronic Load

A transistor or other device can have it's resistance varied

electronically and so acting as a programmable load. The

mode of operation can be as simple as looking like a resistor,

or a more useful mode looking like a constant current.

Amrel EL1132

Electronic Load

This is a bench top electronic load

test instrument that can be set to look like a constant

resistance, current, power or voltage load. By using a

computer to control the load and read back the battery voltage and

current almost any test sequence can be accomplished. There

is a low voltage limitation of 2.5 Volts.

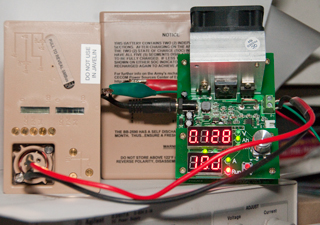

ZPB30A1 "Constant Current

Electronic Load 9.99A 60W 30V Battery Discharge Capacity

Tester"

The quoted title of this paragraph is the same as the eBay

title for this made in China tester. eBay seller ayanhu81

(about $20). The same seller also has a "Four Wire Battery

Holder Battery Resistance Test for 18650 26650" that works with

the capacity tester. See a nicer BF-1L

4-wire battery holder below.

Note this unit has no charging capability, it's only a constant

current load or capacity tester. Can also be used to test

sources like wall warts, power

banks, &Etc.

Technical

Review -

Youku video (Mandarin): Use as

Constant Current Load -

Youku video (Mandarin): Use as

Battery Capacity Tester -

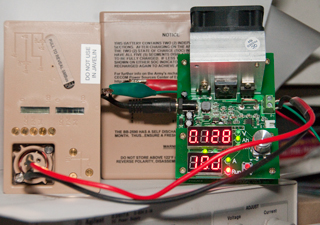

Fig 1

|

Input power: 12 VDC <= 0.5 (0.1 typ)

DC power connector: 5.5 x 2.1 mm.

Power up display: 03.0u Volts & 0.21 Amps

|

Fig 2 as received was in Constant Current

Load mode (Fun 1)

|

The top display stays fixed on Volts

Before inserting the power plug,

hold down the red button, then plug in power.

Turn knob so that Fun 2 appears, then press knob.

unplug power.

Now unit will come up in Battery Test (Fun 2) mode.

The other parameter that shows up after the Function is

the beep mode on or off.

|

Fig 3 after changing

into Fun 2: Battery Capacity mode

|

1.00 Amp constant current load, 14.4V cutoff

The top display rotates between: Voltage, Ah & Wh . .

. .

This battery is a 4S Li-Ion BB-2590 (BT-70791BK1).

Probably 225 Wh, but we'll see.

Note the voltage displayed (16.07) matches what I read

with a FLuke 87 DMM (16.07), so for a 1 Amp load and these

short wires the IR loss is about zero.

|

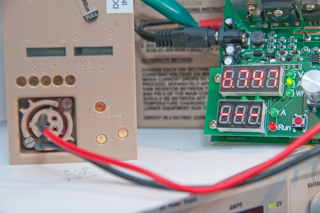

Fig 4 At end of capacity test

|

Note the State Of Charge bar graph on battery shows 1 bar

here and in fig 3 above shows all bars.

Tester reads 6.747 Ah, 15.18V & 102.4 Wh

Test was run with 1.00 Amp load & cutoff @ 14.4V.

|

This is a handy gadget that not

only measures voltage and current but also has an internal clock

so that it can count coulombs. This allows displaying Amp

Hours and Watt Hours. It's a natural to have power

pole connectors on the input and output. A battery might

be the input and a motor might be the output, or a battery

charger might be the input and a battery on the output.

For measuring voltages below maybe 4 volts an external power

supply is needed. There's a 3 male pin connector next to

the SOURCE wires where an external battery can be connected to

power the Watt's Up when testing below 4 Volts.

wu100v2_user_manual.pdf

(at

RC Electronics)

|

|

Watts

Up Coulomb counter

|

Aux

battery connected to allow working with voltages below

4.

With test leads shorted there's a reading ov 0.05

volts.

Org : gnd, Red:+9 drawing 5 ma Brn: Reset when

grounded.

Aux

cable at PowerWerx

|

Ni-Cad, Ni-MH or Li chemistry

charger discharger with LCD readout of parameters. Does

packs.

Intended for Ni-MH AA or AAA

cells. Only tests single cells, not packs. Four

independent channels and can do different things to each

channel.

Multipurpose Charger Discharger

Cycler for a number of chemistries with plenty of

adjustments. One battery at a time. Can do packs.

iMAX B6 LCD Screen Digital Lipo NiMh

Battery Balance Charger

1.5v~12v Battery Capacity

Meter discharge Tester 3.7v 18650 lithium lead-acid

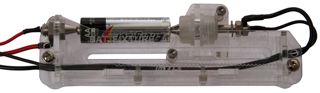

BF-1L Battery Fixture (Single Cell)

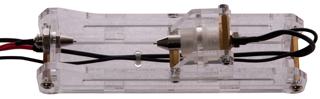

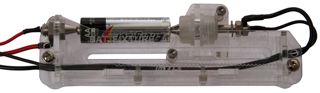

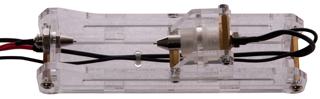

This is fixture was laser cut from clear acrylic and the saw

tooth bed has markings for 34, 44, 49 & 65mm long

cells. It is a Kelvin fixture with separate wires for

forcing current and sensing voltage. The negative

terminals are spring loaded. Fastech BF-1L

BF-1L battery Fixture with standard AA cell

on 44mm setting

|

BF-1L battery Fixture w/o a battery

|

Internal Resistance

Any resistance inside a battery will generate heat during

charge or discharge. It also limits the maximum current a

battery can supply. Classically secondary batteries, like

lead acid, are used for high current applications because of

their very low internal resistance. I tried to measure the

internal resistance of a Leclanché

Battery with a Fluke 87 DMM and

burned out the internal fuse because it could supply much more

current than I expected.

This is very similar to, if not identical to, to concept of ESR

(Wiki

Equivalent Series Resistance) in capacitors. A high ESR

means that the capacitor can not do as good a job as another

capacitor with a much lower ESR.

The use of an amp meter to "Flash Amp"

test No. 6 dry cells is based on looking for both charge and low

internal resistance.

Examples

Table of Maximum

Available Current for RC rechargeable battery packs

nominally 7.2 Volts.

Internal Resistance is approximately Nominal Voltage / Flash Amps -

"D" cell 1.5 V / 13A = 0.12 Ohms (but the resistance of the

Flash Amp meter needs to be subtracted.)

Ryobi Tire

Inflator Battery Internal Resistance - both are "18 V, 4.0

AH";

Not much different?

Model

|

Voc

|

Ri

|

Flash

Amps

|

| PBP005 |

20.7 |

0.0451 |

459

|

PBP004

"Hi Performance"

|

20.5

|

0.0432 |

474

|

Black

& Decker LST522 String Trimmer - these are all standard

batteries, comparing 2.5 AH with 4.0 AH batteries.

SM8124 (20R) Battery Impedance Meter

I let the smoke out of my ESR-Cap meter when trying to measure

the internal resistance of some 7.2

Volt RC batteries, so found this unit from eBay seller hkwisefield

(eBay search for Internal

Battery Resistance Tester).

The top switch is Off-Ohms-Volts and the bottom switch is

100V/200mOhms-20V/2 Ohms- 2V/20 Ohms.

There are two wires to each test probe (i.e. Kelvin

connections) to cancel test lead resistance. But only a

single terminal.

The test signal is about 1 kHz at more than 1 VAC.

By using an AC test signal the meter can use AC coupling for the

resistance measurement keeping DC out of the test circuitry.

The AC test signal also has the advantage of not being

influenced by voltages caused by thermal differences at metal

junctions.

To replace the 9V battery peal the rubber case from the top

side just enough to get to the battery compartment.

PS this meter is also called "20R" and there is a very similar

meter called SM8124 that's for measuring UVA and UVB light.

For a practical application see testing RC Car 7.2 Volt battery

sticks for Maximum Current by

measuring battery resistance.

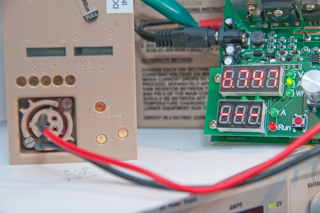

SM8124A Battery Impedance Meter

The "A" version adds Kelvin

connections to replace the single terminal connection used

on the SM8124 version. So now each probe has two spring

loaded terminals. This should improve the accuracy by

eliminating the probe to DUT resistance.

Have this on order (Dec 2021, Rcvd: 2022 Jan 5) in the hope

of testing the internal resistance of some tool batteries, like

the Riobi

and Black

& Decker.

eBay title "Battery Resistance Voltmeter Internal Impedance Meter

LCD Rechargeable SM8124A" from seller tangzhimin1008.

Came in a hard carry case which I like better than the soft carry

case shown in the eBay ad.

Uses a single 9V battery.

Resistance test drive (measured with Fluke 87V DMM)

Ohms

Range

|

ACV

|

Hz

|

20

|

1.29

|

1042

|

2

|

1.64

|

1042

|

0.2

|

1.69

|

1042

|

Fig 1

|

|

EVB ESR/Low Ohms

Meter

You can use one of the

hand held capacitance ESR meters

to measure the resistance of individual cells and of battery

packs. But first a couple of modifications need to be done.

You can use one of the

hand held capacitance ESR meters

to measure the resistance of individual cells and of battery

packs. But first a couple of modifications need to be done.

(1) The two large protection diodes need to be removed from the

PCB. They are located near where the banana jacks are wired.

(2) A SPST normally open push button switch is added near the tip of

one of the test leads and in series with the lead. Across the

switch place a 470 ohm resistor. When the probes are first

connected to a live battery the 470 Ohm series resistor pre charges

the internal non polarized blocking caps without hitting them with a

really fast rise time pulse, thus tending to protect the internal

circuitry.

To make a measurement first do the

calibration by:

- push both probe tips onto a good conductor (like on a PCB) [do

not touch the sides of the probes together since you will not

get as good a connection, same for when actually testing, use

the points].

- press the SPST probe switch and while holding it press the

meter cal button.

Then to make a measurement:

- press both probe tips onto the contact points to be measured,

then, press the probe tip SPST button to make the measurement.

The meter I'm using from

EVB in

Portugal, is the same circuit designed by

Bob Parker

and sold by

Dick Smith

Electronics in Australia as a kit. I saw mention

of battery testing at

Hints for techs

using Bob Parker's ESR meter(kit)... and an email from

Bob suggested the switch and resistor to reduce the likelihood of

damage to the meter.

I'll be using it to

test the battery

packs for my 5590BA Battery Adapter.

I haven't tested the 4328A on a

battery but it's my recollection that it's rated for up to 150

Volt batteries. More modern meters are limited to 42 Volts

because of human safety considerations, so there's still demand

for the HP 4328A meter for testing between 42 and 150 Volts.

The ESR-Cap meter can easily

measure internal resistance. See the example

table of data. But the

early versions without internal protection circuitry can be

damaged if an attempt is made to test a capacitor charged to a

very high energy level or connected in reverse polarity.

Dynamic Resistance

This is a concept first patented (3873911)

by Champlin for testing lead acid storage batteries. He

choose a square wave test frequency of 100 Hz and measured the

battery internal resistance.

Snap-On patented (5773978)

an improved version where they used better circuitry to get more

sensitivity and resolution.

Snap-On patented (7657386)

a Battery Service System that connects to the battery but checks

the alternator and starter.

1. System Test

2. Battery Testing & Charging

3. Starter Test

4. Alternator Test

5. Noise Test

6. Multimeter

Shelf Life

New for me Oct. 2007 are the "Ready

to Use" rechargeable batteries. Sanyo eneloop brand in AA

Ni-MH format. Capacity of 1.9 to 2.0 AH. Testing

capacity can be typically done in less than 24 hours, but shelf

life may take months or years. See the eneloop

Ready To Use

battery web page for the test plan.

self-discharge (

Wiki)

causes most rechargable batteries to loose charge just sitting.

Also see the paragraph on

Li-Ion battery maintenance and the associated video.

Analyzers

A battery analyzer has the capability to both charge and

discharge a battery and make measurements of it's parameters, so

is more than either a battery tester or a battery charger.

Cadex C7200 is a 2-bay battery analyzer mainly built for

Ni-Cad, Ni-MH, lead-acid but also can do some Li-Ion battery

stuff.

The HP 6633A can work in two quadrants and so can both charge

and discharge a battery so software could be written to use it

as a battery analyzer (or a battery simulator).

YouTube - 6632B battery

test software - 6632 is 20 V @ 5 Amps, the 6633 is 50V @ 2

Amps. testing 1850 3 Ah cell.

Christie makes a number of battery analyzers, like TS-3997/U

NSN: 6625-01-227-9615. This appears to the a relabeled

CASP/2000 battery tester aimed at Lead-acid and Ni-Cad aircraft

batteries. Not Li chemistries.

Flash Amps

This is the current a battery can

source when a load of 10 milli Ohms is applied for 200 milli

seconds. So far the only mechanical relay I've found that

can handle 40 Amps (needed for "D", "F" and

No. 6 dry cells)

with

a contact resistance will below 10 milli Ohms is the one

used in car starter motor circuits typically rated for 400

Amps. Solid state devices have way too much

resistance. A method of getting the required load is to

connect just under two feet of 14 AWG copper wire across the

terminals. The problem is only connecting it for 200

milliseconds and then disconnecting. If left connected

longer serious problems with the battery or load may occur.

Links

Back to Brooke's PRC68 home, Products for Sale, Battery,

Battery Chargers, Battery Patents, Leclanche,

No. 6 Battery,

Military Information, Personal Home page

page created 13 Oct 2007.

Aug 2007 -

Added test jack table to

TS-183 web page so that the Radio Shack load resistors could be

compared to the TS-183 load resistors. The Radio Shack

tester showed a 9 volt battery as good yet the battery would not

work in the Stamps.com postal scale. The TS-183B showed the

resistor as bad after abut 5 to 10 seconds. There's a 100%

difference in the load resistors for this voltage. Need to

check the others.

Aug 2007 -

Added test jack table to

TS-183 web page so that the Radio Shack load resistors could be

compared to the TS-183 load resistors. The Radio Shack

tester showed a 9 volt battery as good yet the battery would not

work in the Stamps.com postal scale. The TS-183B showed the

resistor as bad after abut 5 to 10 seconds. There's a 100%

difference in the load resistors for this voltage. Need to

check the others.

You can use one of the

hand held capacitance ESR meters

to measure the resistance of individual cells and of battery

packs. But first a couple of modifications need to be done.

You can use one of the

hand held capacitance ESR meters

to measure the resistance of individual cells and of battery

packs. But first a couple of modifications need to be done.