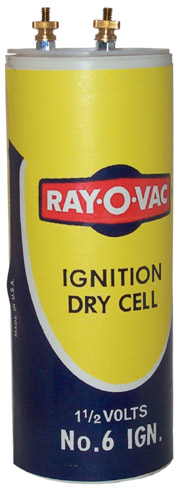

No. 6 Dry Cell

Brooke Clarke 2007 - 2024

Background

Third Prototype

Second Prototype

Post Mercury Ban Alkaline

Modern No. 6 Battery

"F" Dry Cell

Comparing Modern No. 6 Dry Cell and a 6 Volt

Lantern Battery

Inside the 6 Volt Lantern Battery

Testing on the Electro-magnetic Toy Engine

The Build it Yourself! a Real Electric Motor kit

Low Cost Battery Adapter

Hardware

Teeth on Pliers

Internal Resistance Measurements

Eveready W.W. II ad for the No. 6 Dry Cell

Flash Amps

Measured Flash Amps

Calculations

Two D Cells Series or Parallel

Seagull R40 Batteries

Joseph Henry

Applications

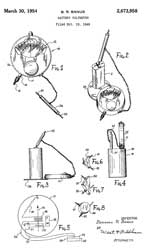

Patents

Eveready Pocket Amp Meter

Sterling Manufacturing Co

Conn Tel & Elec Flash Amp

Meter

Dual Range Pocket Voltmeter

Yankee Volt_Ammeter

Links

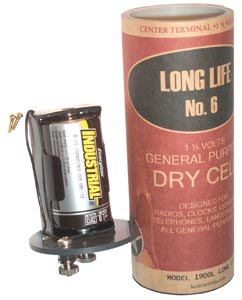

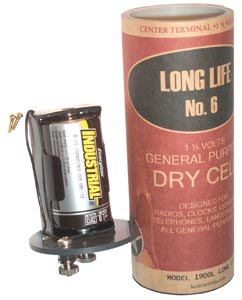

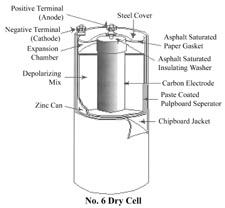

Background

The

wet

battery gave way to the dry cell opening up many portable

applications that were not possible with a glass jar full of

liquid chemicals. These first generation Zinc Carbon cells

were the common type through the

Korean

Conflict. They consisted of a Zinc cup which is

the negative terminal just like the Zinc in a wet battery is the

negative electrode. The metal cap on the carbon rod is the

positive terminal. Some type of insulating material was

poured between the cup and rod at the positive end to seal the

battery. The label was a cylinder of single layer cardboard

on

flashlight

batteries and there was a bottom cap on the No. 6 Dry

Cell. Modern designation is LR40 for the size or ALR40 for

Alkaline. The body of a No. 6 Dry Cell is 2½" diameter and 6"

tall. The terminals are #8 Thumb nuts or optionally

Fahnestock Clips.

The Zinc gets consumed in this chemistry so if a battery is left

connected to a load or just left on the shelf, after some time the

Zinc will have holes that allow the liquid electrolyte to leak

out.

Maybe the No. 6 came after No. 1 through No. 5? The No. 6

replaced glass batteries on a one for one basis in clocks,

telephones and many other applications. In the 1950s these

were available in almost any hardware store. In 2007 they

are only available from specialist internet or mail order houses.

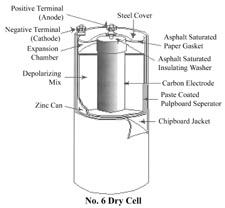

I think this drawing is from the 1980s so may be the last

incarnation of a real No. 6 Dry Cell.

In TM 5-234 Topographic Surveying 1953, wiring diagrams are shown

for No. 6 batteries where the voltage is 1.5 Volts per cell and

the current is 24 Amps per cell. Paragraph 243 Power Supply, page

138, Fig 31 Methods of Connecting Batteries.

Third Prototype

The simplest (lowest cost) version that retains excellent flash

amps uses a single "D" cell battery holder. Top hardware is

# 6 so the optional #6 Fahnestock Clip will fit. Internal

heavy wiring is soldered to the battery holder and crimp to # 6

ring tongue terminal.

Instead of putting a terminal in the center, it's offset a little

to provide a 1 inch center to center distance between the two

terminals. This is the unit shown above with the Ray-V-vac

label.

Second Prototype

This is

based on the same concept of using test caps for the ends and PVC

pipe for the tube. I've found a combination of fittings that

allows the user to choose either Fahnestock Clips or thumb screws

(maybe also an option for Wing Nuts which were commonly used in

Europe then you don't need pliers to tighten the thumb nuts.

Ever wonder what those "teeth" on pliers were

for?). Note if you add Fahnestock Clips under the thumb nuts

then you can not depress the clip far enough to insert a tip

pin. Notice there's a tip pin installed in prototype 2.

This is

based on the same concept of using test caps for the ends and PVC

pipe for the tube. I've found a combination of fittings that

allows the user to choose either Fahnestock Clips or thumb screws

(maybe also an option for Wing Nuts which were commonly used in

Europe then you don't need pliers to tighten the thumb nuts.

Ever wonder what those "teeth" on pliers were

for?). Note if you add Fahnestock Clips under the thumb nuts

then you can not depress the clip far enough to insert a tip

pin. Notice there's a tip pin installed in prototype 2.

The electrical design is aimed at minimal resistance and low cost.

There are a number of possible electrical configurations:

- Single "D" cell for 1.5 Volts

- Two series connected "D" cells for 3.0 Volts. This

is what's been powering my 19" square Self Winding

Clock Co. "Western Union" clock for a number of

months and it still sounds like an air compressor when it

winds. Using a single battery adapter and bypassing

the wires and connections that would be needed to connect

two adapters makes for lower resistance.

- Two "D" cells in parallel for 1.5 Volts and even lower

resistance.

- Single "F" cell for very low resistance.

- Two parallel "F" cells for performance about the same as

a real No. 6 Dry Cell.

I have workable low resistance designs for all but the two "F" cell

version.

If you are interested in purchasing one of these let me know your

application.

This test was done on the EL1132

Electronic load. It's specified to work down to 2.5 Volts so

the No. 6 Battery Adapter was configured with two series connected

Duracell copper top "D" cells for a nominal 3 volt output.

Fitting a straight line to the measured Volts vs load current over a

range of 0.1 to 3 Amps gives the following equation:

V = -0.3428*I + 2.9734 and R2 = 0.912 where R is a measure of

the fit.

This says the internal battery voltage is 2.9734 and the resistance

of everything in the test setup including the internal resistance of

the battery is 0.3438 Ohms. If all of that resistance was

inside the battery adapter then the Flash Amps (see

below) would be about 8.6. If 1/3 of the resistance was

the battery adapter, 1/3 the wires to the Power Pole connector on

EL1132test wires and 1/3 the test wires from the power pole to

the EL1132 bus bars then the flash amps would be about three time

more or just short of 26 Amps.

The ESR meter shows 0.16 Ohms at the top of the 6-32 terminal screws

and essentially the same reading across the two D cells, so the

resistance of the wiring and connectors is minimal.

The HP 34401 in 4-wire Ohms shows 13 milli ohms for black and 17

milli Ohms for red or a total of 30 milli ohms for all the wires

from the battery holder to the power pole connectors.

Testing just the ring terminal wires to the Power Pole connector

shows 8 milli ohms for the red and 8 milli ohms for the black.

Summary of milli Ohms

EL1132

|

342.8

|

ESR meter

- wires & batt

|

160

|

ESR meter

- just 2 D batt

|

160

|

ESR

- just all wires

|

30

|

HP 34401

- just all wires

|

30

|

HP 34401

- just test wires

|

16

|

So all the wires look like 30 milli Ohms and the two Duracell D

batteries are probably about 130 milli ohms. There's probably

some resistance in the battery holder terminal to battery joint.

Post Mercury Ban Alkaline

The

current version of the No. 6 is no longer a Carbon Zinc, but a

post Mercury ban Alkaline. This type of alkaline cell is the

common type on the shelves of all kinds of stores that sell the

common AAA, AA, C, D and 6 Volt lantern and 9 Volt transistor

radio batteries.

The Zinc Carbon cell uses Amalgamated Zinc which means Zinc that's

been treated with Mercury. The first generation Alkaline

cells also used Amalgamated metal (I forget but it may have been

Zinc). So when Zinc could no longer be used in batteries a

whole new generation of Alkaline batteries was developed.

The bulk of the

patents you see on

any Energizer battery package are related to making a Mercury free

alkaline cell.

The top button, top surface and cylindrical surface is the

positive contact. The center of the bottom is the negative

contact. This is very different than the old Zinc Carbon

where only the button was the positive contact.

This can cause shorts in some applications that were designed for

Zinc Carbon cells, like the

PSR-1 Seismic

Intrusion Detector where the battery clips can cut through

the thin plastic label on a modern battery and short the positive

battery terminal to chassis ground which is the negative terminal.

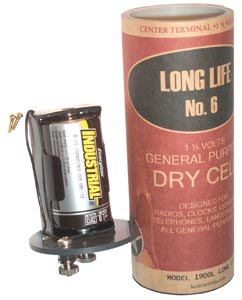

Modern No. 6 Battery

The No. 6 battery

that's being sold today is no longer a single cell that's the same

size as the old No. 6, but instead is a plastic shell that holds a

couple of "F" size modern Alkaline cells connected in

parallel. The reason for connecting them in parallel is two

fold.

First by paralleling a couple of "F" cells the capacity of the

modern No. 6 probably approaches that of the original Zinc Carbon

No. 6.

Second by paralleling a couple of "F" cells the internal

resistance of the modern battery probably approaches that of the

original Zinc Carbon No. 6.

I've been studying a number of products based on electromagnets

like the

Self Winding Clock which was

designed originally (1884 - 1930) for a couple of wet batteries,

and the later clocks (1930 to 1960) were designed to be powered

from two each No. 6 Dry Cells. The Build it Yourself! a Real

Electric

Motor kit was designed to

run from a single No. 6 Dry Cell and I think the

Electro-Magnetic Toy Engine was

designed to run from a couple of No. 6 Dry Cells.

The interesting thing is that the coil resistance for the two

motors is a small fraction of an Ohm. The modern No. 6 has

an internal resistance of 0.1 Ohm and so will power these motors.

Note that the actual motor current is being set by the

battery's resistance and so it's the key specification. But

a "D" cell has 2 to 3 times the internal resistance and so will

not do a very good job. In this case the problem is

not the amp hour capacity but rather the high internal resistance

of the "D" battery.

Notice the plastic shell on the left has an indentation for the

battery. That's because the outside diameter of two "F"

cells side by side is less than 0.1" less than the maximum

diameter of a No. 6 dry cell. So by thinning the plastic on

both sides right next to the cells the overall diameter will meet

specifications. I can not close this unit maybe because it's

old the the batteries are starting to swell? Two "F"

cells side be side are wider than the outside of a 2" PVC pipe.

There are two metal ribbons spot welded to the "F" cells and an

eyelet or tubular rivet type connection to the bottom of the screw

terminal posts. They are 0.005" thick by 1/4" wide and 2

3/4" long, probably nickel. These are probably 6 milli-ohms

each or 12 milli-ohms for both of them.

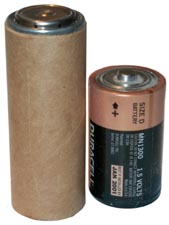

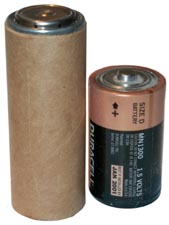

"F" Dry Cell

This cell is the same diameter as the common "D" cell but is 1

inch longer. The "F" dry cell must have been one of the very

early dry cell sizes since a pair of them fit and properly power a

railroad lantern from

prior to 1937. If you know what these were called back in

the early 1900s please

let me know.

This is a modern post Mercury ban

"F" Alkaline dry cell. It has a single layer cardboard

sleeve slipped on to act as insulation between adjacent cells.

The "F" cell has an internal resistance in the 150 to 200 milli

Ohm range, so two in parallel will be about 75 to 100 milli Ohms (

< 0.1 Ohms).

The can is the positive terminal on an F cell and the cap shown at

left on the top is the negative terminal.

Comparing Modern No. 6 Dry Cell and a 6 Volt

Lantern Battery

This photo gives you the idea that the "F" cells used in the

modern No. 6 Dry Cell are that same as the cells used in a 6 volt

lantern battery.

It would make sense that by combining 4 "F" dry cells in series

you would get a 6 volt battery.

Note "Cell" or "Battery"

A Cell is a single package consisting of the anode and cathode

terminals plus the necessary chemicals to make electricity.

A Battery is made up of a number of cells. This is the

same usage that's applied to an artillery battery made up of a

number of guns or cannons.

So "Cell" is the correct word when talking about "AA" or

"D" or No. 6 and "Battery" when talking about the 6 volt

lantern battery.

Inside the 6 Volt Lantern Battery

After bending back the metal on

the bottom of this Energizer 6 Volt Lantern Battery (model 529)

the following parts are found:

Going clockwise. 4 each "F" cells in cardboard insulating

sleeves. Energizer sells the "F" cell with or without the

cardboard sleeve.

The plastic top with two terminals and one battery to battery

jumper strip.

A cardboard square with two battery to battery jumper strips.

A metal plate with the four corners bent up that pushes on the

plain side of the double jumper strip cardboard.

The bottom square cardboard.

The sheet metal outer case.

Note that there are no welded straps, all the electrical joints

are pressure contacts. Also there is what appears to be

Silicon grease on both ends of all the batteries and on the jumper

strips and terminals. This is an insulator, but would act to

keep air away from the joints thus preventing oxidation.

This may be the same patented

5037566

type that Radio Shack sells as Lube-Gel where there is no

entrapped oxygen.

23 Feb 2008 - needed a 6 volt lantern battery to work on an

Adams-Westlake Railroad lantern

and the above unit is no longer useful that way so got the other

one. It's an Eveready 1209. The 1209 weighs 1 pound

3.7 ounces 19.7 oz). Most of the parts of the 529 weigh 1

pound 15 ounces, probably over 2 pounds (32+ oz) with the

missing parts included. The price and energy content

probably are about proportional to the weight.

My Agilent E3617A bench power supply

rated for 0 to 80 volts at up to 1 Amp will not power the Toy

Engine. The stock 6 volt Lantern battery does power the

engine. The resistance of the two series connected

electro-magnets is about 0.2 Ohms. So connecting a 6 volt

battery might cause a current of 30 Amps to flow, but that can't

happen because the current is limited by the battery. It

turns out the same Energizer battery that I took apart above

demonstrated a resistance of 0.4 Ohms when powering this Toy

engine which along with the resistance of the clip leads limited

the current to about 8.5 Amps (way more than my bench supply can

deliver).

"D" Cell

If the negative end of a "D" cell is held directly on one of the

Toy Engine terminals (to eliminate one clip lead's resistance) and

a clip lead is connected to the other Engine terminal and it's end

held to the "D" cell the engine barley turns over.

Connecting two "D" cells in series runs the Engine at a

respectable rate.

"F" Cell

If the same setup as above is used with an "F" cell the motor is

running at a respectable rate. By holding a couple of "F"

cells in parallel (no cardboard) and using a clip lead to touch

each positive terminal there is not a noticeable

improvement. When two "F" cells are held in series the motor

runs at a faster rate. The spark at the comutator is

brighter and stronger with the "F" cells as compared to the "D"

cells.

The Build it Yourself! a Real Electric Motor kit

The wire that comes with this kit

has a total resistance (for motor electro-magnets and all the hook

up to the No. 6 Dry Cell) of 0.08 Ohms. The instructions for

the motor say it will develop 6,000 RPM from a single No. 6 Dry

Cell. A 1.5 Volt cell with no internal resistance would

deliver just under 19 Amps and a No. 6 with 0.1 Ohms internal

resistance would deliver 8.3 Amps! About the same as the Toy

Engine is drawing. Seeing this is what got me looking hard

at the No. 6 specifications. It's the only Dry battery I've

seen that has specifications on internal resistance (0.1 Ohms at

room temp).

Low Cost Battery Adapter

At the top of this page is shown a

low cost No. 6 Battery Adapter. It's made from 2" PVC pipe.

Construction

of Western Union Clock Battery Packs by

N7CFO.

If you're interested in getting a kit to build this

adapter let me know

I have way more 2" PVC than I need and also have the Rigid

cutter for it.

See it in a

Sweep Second Hand Self

Winding Clock.

Hardware

This is some

terminal hardware consisting of:

* 6-32 Brass screw that will be in the low cost No. 6 Dry Cell

Battery Adapter. They can also be used for Do It Yourself

electrical circuit terminals.

* #6 Brass Nut that can be used to pinch the top of the battery

adapter or for making electrical connections.

* #6 Brass Thumb Nut for making electrical connections. An

option to the thumb nut is the wing nut which allows applying more

torque without resorting to pliers.

* #6 Fahnestock Clip for connecting to wire ends, or better as

shown

* Tip Pin wire termination. These were a very common way of

terminating wires in a way that's much more rugged than just using

the wire itself. Headphones commonly used tip pins.

Western Union clocks (

Self Winding Clock Co,

#2) use these to make it easy for a man

on a ladder to change the No. 6 Dry Cells.

Not shown but also in stock are 8-32 Screws, Nuts, Thumb Nuts and

Brass Washers for both #6 and #8 hardware.

Teeth

on Pliers

Teeth

on Pliers

On most ordinary pliers there are teeth behind the jaws, i.e.

closer to the hinge pin. For a long time I wondered why they

were included. For example if you use them on pipe or any

smooth round object they do more damage and typically don't grasp

well enough to actually do any good. The answer may be they

are for tightening thumb screws.

The No. 6 Dry Cell is capable of very high currents, (See

Flash Amps below) and a

number of applications use these high currents so good electrical

joints are needed. Finger tightening may not be good enough.

The original Leatherman Tool shown at left has the teeth that look

about like what I remember on everyday pliers. Note that a

homeowner in the late 1800 through the mid 1900s might have a

number of devices that used the No. 6 Dry Cell and so a tool to

tighten them would be a common requirement.

I've read that in Europe Wing Nuts were more popular than Thumb

Nuts because you could get more torque on a wing nut using just

bare hands than was possible with Thumb Nuts.

My local hardware store stocks bronze wing nuts in 6-32 and 8-32,

the two common sizes for No. 6 Dry Cell terminals. Note

bronze offers both good electrical performance and mechanical

strength. The other wing nut sizes are steel.

If you know about the teeth on pliers please

let me know.

Internal Resistance Measurements

By using a slightly modified

Equivalent Series Resistance (ESR) meter

intended for use checking electrolytic capacitors it's possible to

measure the resistance of a live battery.

Energizer white paper on

Battery

Internal Resistance. Mentions "Flash Amps" which is

the current into 0.01 Ohms applied for 200 milli seconds.

Battery

|

Ri Ohms

|

No. 6

Spec

|

0.101 |

| Modern

(old) No. 6 |

0.051 |

F cell

|

0.02 -

0.041

|

D cell3

|

0.06 -

0.09

|

6 volt

lantern

meas on Toy engine

|

0.42

|

Low

Cost No. 6

3 V Battery Adapter

w/ 2 series "D" cells

|

0.36

0.154

|

1.5 V

KCC Single "D"

1900

|

0.22

|

1.5 V

KCC Double "D"

1900-L

|

0.12

|

Seagull

R40

|

0.00

|

Note 1 - The actual resistance for a fresh No. 6 is probably in

the 0.02 to 0.03 Ohm range (i.e. two F cells in parallel plus a

little).

Note 2 - It appears that there is resistance in the 6 volt

lantern battery caused by the two spring contacts, the 3 jumper

bars and the 8 joints between the dry cells and the bars or

terminals that amounts to the bulk of it's resistance. Not

measured using the ESR meter, since it was taken apart prior to

these measurements.

Note 3 - the

Energizer

EN95 "D" cell is specified at 0.15 to 0.3 Ohms.

Note 4 - 10 Oct 2007 measured on low resistance version of low

cost double "D" 3 volt adapter with Duracel batteries. Note

that when two battery adapters are used in series, like in a Self

Winding Clock Co. installation, you end up with twice the

resistance, so in the common case of a single "D" cell in a radio

shack battery holder that may be 0.44 Ohms.

A better way to measure the internal resistance would be to use a

shunt resistor in series with a static load and use a DVM to

measure the voltage drops around the circuit. If a dynamic

load, like a motor is the load then a scope would be needed to

measure the current.

If a 6 Volt Lantern battery is used to power a motor with a

resistance of 0.08 ohms and the battery had 0.4 ohms resistance

and perfect wires are used then about 1 volt will end up across

the motor and the other 5 volts will be in battery loss

resistance. So using a real No. 6 battery or a battery with

an equivalent low resistance will work much more efficiently.

Eveready W.W. II ad for the No. 6 Dry Cell

Flash Amps

Defined as the current into 0.01

Ohms applied for 200 milli seconds. I've been thinking of

how to measure Flash Amps.

A little less than 2 feet of 14 AWG wire has a resistance of 0.01

Ohms, i.e. 10 milli Ohms. So connecting that length of bare

copper wire to a battery will provide the correct load.

Soldering some small stranded wire separated by a little less

length would provide the test leads to a voltmeter so that the

voltage along the wire can be measured. If the leads were

about 12 inches apart the resistance between them would be about

0.005 Ohms and if 20 amps were flowing the voltage would be 100

mv. The HP 34401 when in a fixed range mode and turned down

to 4 digits can make a measurement each millisecond and store

them. It can also be started in this mode from a switch

closure input to TRIG on the rear panel.

17 Nov 2007 - About Pocket Watch Ampere Meters

The early automobiles used "Ignition Batteries" which were

No. 6 Dry Cells. There were two ways

of testing them, you could measure the terminal voltage or the

terminal current. Pocket watch size meters were available as

either a voltmeter, amp meter or a combined meter. A book of

the time recommended that if you could only get one the amp meter

was the most important. The example given was that a dead

battery and a fresh battery read very close to 1.5 volts, maybe

1.5 down to 1.2 volts a very small amount of deflection (3% of

10V) on a pocket watch size analog voltmeter. But the amp

meter would read 10 amps or less for a dead battery and 16 Amps or

more for a good one. Which would be 20% of 30 Amps.

The method was to line up the available No. 6 Dry Cells on the

counter and holding the pocket meter in one hand and the test wire

in the other hand make a firm connection to the battery terminals

(observing polarity) and as soon as the meter needle was steady

remove the meter and remember the reading. I doubt that

there was a "Flash Amps" specification at the time. The spec

was probably made to reflect what was being done.

A loose-leaf book titled "Battery Engineering Data" by the

National Carbon Co., a division of Union Carbide and Carbon Corp.

has data sheets on what may be the full line of Eveready

batteries. At the time the book was written National Carbon

Co. maintained a research lab with equipment to test the RF and

audio characteristics of battery powered radios so that batteries

could be developed to optimally power the radio. There were

different ways of using the "A" and "B" batteries and different

problems associated with either a weak "A" or weak "B" battery in

different designs of radios. When the internal resistance of

the "B" battery is excessive (the battery is going bad) the radio

"motor boats". So far I have not found a date anywhere

in the book, but there is quite a discussion about "B" batteries

made up of flat cells instead of cylindrical cells and references

papers with dates as recent as June 1941.

The book mentions that measuring the terminal current of a battery

does NOT tell you much about how much charge is remaining.

The book about early automobiles was from the late 1800s so by

1941 Measuring Flash Amps was not as popular.

The Battery Engineering Data book shows the terminals on Eveready

No. 6 Dry Cells as 8-32, not the 6-32 that's common on the Chinese

battery. The Brentronics military unit has the proper #8

hardware.

15 Dec 2007

Measured Flash Amps

Using the Conn Tel & Elec Co Inc Flash Amp meter.

|

2 F

cells Parallel

|

|

F

cell

|

|

|

|

|

|

2 x F

|

Seagull

|

F

|

2 x D

series

(no springs)

|

2D

Series

|

2D

Parallel

|

1900L

2 x D parallel

|

1900L

single D

|

Flash

Amps

|

29

|

26

|

23

|

16

|

14 -

E95

17 MN1300

|

23 -

E95

24 - MN1300

|

11

|

7

|

More Flash Amp Measurements

Made on batteries close at hand, condition unknown

Battery

|

ZTS1

# bars

|

Flash

Amps

|

ZTS

# bars

|

Duracell

MN1300

"D"

|

3

|

4

|

4

|

| Duracell

MN1400

"C" |

3

|

4

|

3

|

Duracell

MN1604

"9 V"

|

5

|

9

|

5

|

Energizer

E91

"AA"

|

4

|

13

|

4

|

Energizer

E95

"D"

|

5

|

13

|

4

|

"

|

5

|

12

|

5

|

"

|

-

|

15

|

3

|

"

|

5

|

12

|

3

|

Energizer

"F"

|

4 2

|

19

|

4 2

|

Radio

Shack 23/872A "AA"

|

5

|

19

|

4

|

Powerizer

(China)

Ni-MH

|

4

|

19

|

4

|

Kirkland

(Costco)

"AA"

|

4

|

8

|

4

|

Note 1 ZTS reado 0 to 5

Note 2 the ZTS is not designed to measure an "F" cell so it's not

surprising that it gives a wrong answer.

Calculations

The open circuit voltage is 1.5

Volts (nominal for a fresh No. 6 Dry Cell or for a single Alkaline

cell like a AA, C, D or F cell).

The voltage across the Flash Amp load resistance of 0.01 Ohm is V

= I * R or V = (FlashAmps) * 0.01.

For example two "F" cells in parallel show Flash Amps of 29 Amps,

then the voltage across the load is 0.29 Volts.

The drop due to the battery internal resistance is 1.5 V - 0.29 V

= 1.21 Volts.

The internal resistance is R = V/I = 1.21 V / 29 A = 0.0417 or

41.7 milli Ohms.

Optimum Power Transfer occurs when the load resistance is equal to

the source resistance. So to get the most power from a

battery the load should have a resistance matched to the batteries

resistance. Primary cells like the No. 6 came in various

versions depending on the load. For example a No. 6 for

telephone use would be designed to supply a small current for a

very long time (a few years). But an ignition battery would

need to supply very high current pulses. So while the

optimum power transfer load works, it also can not be maintained

for very long since the drain is maximized.

Electromagnet Idea

An application would be making an electromagnet where you are

restricted to use only a single "D" cell battery. Since the

Flash Amps for a good "D" cell are around 15 A the voltage across

the load is 0.15 Volts. The drop across the internal resistance is

1.35 V and the internal resistance is about 0.090 or 90 milli

Ohms. So the load should be 90 milli Ohms. If the core

of the electromagnet is a "C" shaped soft iron 1/4" diameter and

is 2" long (with the ends cut off in the same plane so the air gap

to the soft iron keeper is minimized) then the best winding would

be one layer deep and covering all of the "C". Different

wire sizes might be used, but the wire size the results in a 90

milli Ohm resistance (including the leads to the battery) is the

best choice. It turns out that winding more layers results

in lower amp * turns since the resistance goes up faster than the

number of turns, also the copper layer next to the core is

non-magnetic so the area inside the winding is partially

nonmagnetic.

Automating Flash Amp Measurements

The problem is turning on and off the current. Bosch type

automotive relays come in current ratings around 20 to 100 Amps

with coil currents under 200 ma for "12 volt" units. The

contacts are rated around 20 milli ohms for initial resistance and

low currents. The Bosch type relays have quick connect push

on type terminals on one end in a standard pattern and are now

made by many companies and used for many applications. But

may have too much resistance for this test. A number of them

could be connected in parallel. By using a high voltage

driver in series with a power resistor the actuation time can be

made very quick (time = k* L/R).

Relay Data

Brand

|

Model

|

Peak

Amps

|

Contact

Amps

|

Contact

Ohms

|

Coil

Ohms

|

Omron

|

G8JN

|

100

|

35

|

?

|

74

|

Tyco

|

T9A

|

na

|

20

|

0.075

|

144

|

Beuler

|

BU5083B |

-

|

40

|

-

|

80

|

There's what's called "Universal Starter Solenoid. 4 pole, 12

volt" these are SPST N.O. relays used for the starter on small gas

powered garden tractors. Rated for 400 Amps (no more than

0.5 seconds which is fine for this.

Stancor type

120.

There are also the starter solenoids like used on cars.

These are rated 780 Amps intermittent or 85 amps

continuous. Contact resistance is will below 1 milli

ohm.

The IRF 6726 might be able to do this, but the RDSon is around 2.6

milli Ohms or about 26% of the allowed resistance.

Antique Leclanché Wet Battery can produce high Flash Amps

When I tried to measure Flash Amps on the

Leclanché wet

battery a fuse in my

Fluke 87 DMM was burned out.

Two D Cells Series or Parallel

This is a

modified two D cell battery holder. It normally has solder

lugs on the two ends and no electrical connection to the

frame. By installing three terminals, one on each end and one

on the frame the battery holder can be used to combine two D cells

in series or parallel.

This is a

modified two D cell battery holder. It normally has solder

lugs on the two ends and no electrical connection to the

frame. By installing three terminals, one on each end and one

on the frame the battery holder can be used to combine two D cells

in series or parallel.

The photo at the left shows two D cells in parallel. The

cardboard tube has been removed to make it clearer, but normally

that tube helps keep the batteries from popping out. The

plastic labels have been peeled off the two D cells and they have

been installed with their positive ends touching each other at the

center. These are Energizer E95 Alkaline D cells, but all the

other brands are the same, i.e. the top positive end and the

cylinder are all positive. Only the center of the bottom is

negative. So the black wire is connecting the two negative

terminals together and the frame terminal is the positive terminal.

For a series connection you MUST have the labels on both cells

otherwise one cell will be shorted. Or remove just the bottom

3/4" of label on both cells which allows them to be used for a

parallel connection and for a series connection place the cardboard

over the bare bottom of one of the cells.

The Rayovac MN1300 has slightly more Flash Amp capacity than the

Energizere E95. But two D cells in parallel comes pretty close

to a real No. 6 Dry Cell for Flash Amp capacity.

This would be a handy way for school classrooms to use D size Dry

Cell batteries for electrical experiments.

Seagull R40 Batteries

I ordered these

from my local Interstate Battery store as their

Dry1725

expecting it to be made like the Energizer EN6 or military BA-23

using two "F" cells. But it's a real No. 6. They weigh

28.5 oz a lot more than the 16.4 oz for the plastic two "F"

type.

I tried to measure their internal resistance with the modified ESR

meter, but it reads ZERO.

Joseph Henry was the first person to

make what today we call an

electro-magnet

which made the DC motor/generator possible. The unit of

inductance is named Henry after him. His coils were

optimized to use a single wet cell or a small number of

cells. The tests I've done on 1 liter type

Leclanché Cells indicates that they

have very low internal resistance. Henry came up with the

idea of winding multiple coils on a common soft iron core then

connecting them in parallel to a single wet cell. Many of

the electro-magnets he made in the 1900s use large diameter wire

and are intended for low high current use. Henry was the

first

secretary

of the

Smithsonian Institute.

I'm trying to determine if Henry was the first to use insulated

wire for an electro-magnet. Schweigger's (

Wiki)

galvonometer multiplier used bare wire and it may be that

Sturgeon's (

Wiki)

electromagnet was wound on an insulated (maybe just a paper wrap)

horseshoe rather than by using insulation on the wire. I

think Henry used his wife's spinning wheel to wrap silk on "bell

wire" (copper wire used to ring servant's bells in large houses my

mechanical movement, not electricity). By insulating the

wire powerful electromagnets can be made.

Applications

The first application was for

ignition of explosive engines. The 1893 the Columbia No. 6

had a rectangular center post and was labeled as an ignition

battery. They were shortly thereafter used in

Lanterns as a more user-friendly

source of power than lead acid storage batteries. The early

telephones (

patents,

phones) used what's now called local

battery operation where each phone had it's own battery and the

No. 6 Dry Cell was used in a large number of phones to replace

wet cells.

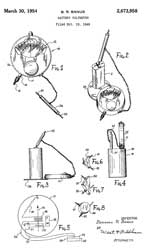

Patents

The key patents were:

G. L. Leclanché Patents for a wet

battery that does not use acid for the electrolyte 1866, 1867 for

key patents, more later.

Columbia Ignition No. 6 Dry Cell made by National Carbon Co. shows

a patent date of April 11, 1893. The only patent issued on

that date applicable to the No. 6 Dry Cell is:

495306

Galvanic Battery, C.J. Coleman, Apr 11 1893,

429/133 ;

429/249 -

Meter

The Pocket Amp meter was the

standard way to check batteries in the early 1900s. While

the literature mentions testing No. 6 Dry Cells with the amp

meter, I think it was used on any battery. Note since it's

essentially a short it can be applied to any battery to measure

it's ability to produce current. Probably not a good idea

to connect to a lead acid car type battery where the current

would be way over the 35 Amps full scale these meters will

measure, but fine for all dry cell batteries like used in flash

lights, radios, and in the ignition circuit of engines.

327908

Electrical Measuring Instrument, E. Weston (U.S. Electric Lighting

Co), Oct 6 1885,

324/93 ;

324/144 - maybe

the first moving coil meter at least the oldest patent in class

324/144

334145

Electrical Indicator, E. Weston (U.S. Electric Lighting Co),-

under glass dome

340399

Electrical Indicator, E. Weston (U.S. Electric Lighting Co),

------------ Edward Weston has a bunch of meter

patents------------

619679

Galvanometer, A.A. Dittmar, Feb 14, 1899, 324/147 - pocket watch

size

686561

Battery-Gauge, Charles R. Underhill (1/2 to Varley Duplex Magnet

Co), Nov 12, 1901, 324/144 - pocket watch case

incuudes two five Ohm

resistors and allows reading the current through 10 Ohms and 5

Ohms to then compute the internal resistance of the battery.

839637 Pocket

Ammeter Dec 25 1906, 324/144 - 270 degree pointer movement, pocket

watch case

854709

Electrical Measuring Instrument, J. Abrahamson, May 28 1907,

324/146 - slotted dial to pass pointer, pocket watch case

1148218

Battery Tester, Emerson L. Clark, National Carbon Co. Jul 27,

1915,

324/145 ; 324/72.5 - a cylindrical flash amp tester

with a micrometer like calibration

1205343

Apparatus for Testing Dry Cells, J.H. Goodwin, F.A. Adamski, Nov

21 1916, - 4 minutes each hour for 10 hours/day for 6 days a week

for . . . .

1262000

Battery-meter,

William

Anthony, 1918-04-09, - iron vane type

Eveready Pocket Amp Meter

966421

Portable Electrical Measuring Instrument, W.E. Beede (American

Ever Ready Co ), August 9, 1910, 324/145 - moving vane gets pulled

into coil

0 to 35 Amp scale.

|

The crown has a socket for

a short wire that's missing. The meter works, but

does not give the same reading as the Conn Tel & Elec

meter. It might be possible to make the plug for the

crown and the cable to go with it.

See the Flashlight web page for a photo of this meter with

a few pocket flash lights, all Eveready barnded.

1906 to 1909 Made by National Inst Co, Hartford, Conn

|

|

Cloth pouch for Pocket Flash Amp meter.

This is wha't called a moving vane meter. The

scickle shaped vane is pulled into the 8 turn coil more

and more as the current increases. The wire is

0.051" dia or 16 AWG which has 3.1845 Ohms/Kft or 3.1845

Milli Ohms per foot. For 10" of wire that's about

2.65 milli Ohms. But the total load resistance of

the test will also include the resistance of the:

- top solder joint

- metal case from the top solder joint to the top

terminal post

- joint between case and top terminal post (on this

meter it's very high since the post can easily be

turned)

- top terminal post

- joint to test lead plug, solder joint, test lead,

solder joint, terminal, contact to battery post

- bottom solder joint

- strap from bottom solder joint to hole for bottom

terminal post

- joint between strap and bottom terminal

- bottom terminal & contact to battery post

|

|

1914 This may be the newest

of the pocket amp meters.

|

1012209

Testing Apparatus,Union Switch & Signal, Dec 19, 1911,

324/418

; 324/157; 338/148; 338/176 - more the size of a flashlight

1184536

Portable Electrical Measuring Instrument, May 23, 1916,

324/145

; 336/130; 336/223; 336/45 - coil a sheet metal stamping, window

to see current

1199829

Battery-Meter, Walter M. Scott,

Sterling Manufacturing Co, Oct 3, 1916,

324/115

; 324/146; 324/149 - frame saves parts and labor

The dial face reads: Simmons Hardware Co., Inc., Mfrs and

Distributors, U.S.A. The

eBay

auction shows the meter face and the pointer is a little

above zero. When the meter arrived in a ReadyPost Photo

Document Mailer with no padding the meter needle and other parts

were loose inside the case. Terminal 3 was loose in the

mailer and external insulator 23 was missing, although shown in

the eBay photo. Very poor packaging.

The meter movement is about 4 milli Ohms, but the wire is 230

milli Ohms. Yet the wire (patent drawing # 4) appears

visually to be OK, it has a serious problem.

Using this wire, not the wire that came with the Conn Tel &

Elec meter the Seagull battery read 15 Amps and the crimp terminal

got very hot.

After doing this the wire resistance is 55 milli Ohms. A

close look at the crimp shows that is was made with the insulation

still on the wire! This appears to be a regular closed

barrel ring tongue terminal, although there is a gap in the barrel

with the insulation showing the full length.

1223306

Electrical Measuring Instrument, 324/146

1315816

Pocket Flash-light Battery and Bulb Tester, R.E. Cole, Sep 9,

1919,

324/444 - uses bulbs and ammeter

1337160

Battery Tester, G.H. Riebeth, Apr 13 1920,

324/437 ;

324/537; 429/90 - connects to the top of a No. 6 dry cell and

reads the current 0 - 30 Amps

Conn Tel & Elec Flash Amp Meter

15 Dec 2007 This meter arrived DOA.

Once the back was off (Kroil helped when prying the back) the

problem was that a Mica washer was used between the terminal lug

on the end of the green wire and the case as an insulator.

The terminal that screws into the outside has what amounts to a

shoulder washer to keep it from touching the case. Mica is

fragile and the washer had broken. It's inside the back

cover on the right. I just cut a small square of 3 x

5" card and used that on the inside as an insulator as a temporary

fix and the meter is now working.

The connector at the top on the green wire and the connector at

the bottom of the meter have cup shaped ends. Just the thing

for putting on the threaded terminal posts of a No. 6 Dry Cell.

The wire connects to the meter using a tappered pin on the wire

that fits a tappered socket on the top meter terminal. It

works like the Morse Tapper used in machine tools like lathes and

drill presses. You push and turn the connector and it makes

an extreamly good joint.

The meter is about 8 milli Ohms and the wire 9 milli Ohms and when

both are measured it's about 15 milli Ohms.

Measuring from the wire connector to the meter connector when they

are mated reads zero =/- 1 milli Ohm. It's a very low

resistance type of connection, far better than a PP15 series Power

Pole.

The

negative battery terminal connector on the test lead shown at the

left is the same as the batery positive terminal connector on the

bottom of the meter. They have a hollow pocket that allows

holding the connector on top of the threaded terminal on the No. 6

Dry Cell.

The wire measures about 10 milli Ohms and the meter is about 8.2

milli Ohms.

But the wire which appears to be stranded 18 AWG has broken

strands. 18 AWG is specified at 6.6 milli ohms per foot and

so 9½ inches should be about 5.2 milli Ohms so it's twice as high

as it should be.

The interesting end is the tapered pin. It fits a tapered

socket on the top of the meter. To make the connection you

press and turn the pin. The resulting connection has

extreamly low resistance. To remove just pull and turn.

The two round parts are some sample shoulder washers that have a

hole about the correct size to replace the broken mica washer, but

I'm liking the card stock more and more.

Just grabbing a number of cells that are nearby shows Flash Amps

when making the connection directly to the battery (no battery

holder) as shown:

D cell: 4 to 15 Amps

C cell: 6 Amps

AA cell: 18 Amps

9 Volt: 10 Amps

18650

1: pegs the needle > 30 Amps

LIR123A

1: 28 Amps and going down scale

quickly

Note 1 When testing these batteries the contact was made and

released in less than a second. The needle does not peg so

much as hits the peg at full scale and bounced back and forth.

The readings from different batteries varies a lot more than a

voltage reading. Since the internal resistance of a battery

is an indicator of it's state of charge the Flash Amp reading may

have more than a passing relationship to State Of Charge.

See more Flash Amps data

above measured with

this meter.

Dual Range Pocket Voltmeter

This

is

a

Voltmeter for checking what were then common battery voltages

which were: 1.5, 3, 4.5 and 6 on the low range and 22.5, 45 and 90

on the high range. Stamped into the case at the bottom

adjacent to the left probe is 90 and adjacent to the right probe

is 7.7. Half way between them is the ground schematic

symbol, meaning a test lead from the top threaded terminal is the

ground connection.

The low range is about 1,000 Ohms per Volt and the high range is

about 10,000 Ohms per Volt.

The readings on the low range are way off, yet the high range is

quite close.

Meter

|

1.5

|

3

|

4.5

|

6

|

7.5

|

22.5

|

45

|

Actual

|

1.33

|

2.48

|

3.81

|

5.12

|

6.54

|

21.4

|

42.2

|

Error %

|

-13

|

-21

|

-18

|

-17

|

-15

|

-5

|

-7

|

After removing the two screws on the back the back cover does not

want to come off. Applied a very small amount of Kroil and

will check again over the next few days. Maybe the reason

for the large error on the low range can be seen.

Note if the error was the same when this no name meter was new

it's easy to see why the pocket amp meters were much preferable to

a voltmeter. The error is close to the difference between a

full battery and a dead one.

|

2673958

Battery voltmeter, Bernard

R Banus, Sterling

Mfg Co, 1954-03-30, - for testing "A" or "B"

batteries. Uses two different coils one for "A"

batteries and another for "B" batteries.

This may or may not be the patent for the Dual Range

Pocket Voltmeter.

|

Yankee Volt_Ammeter

0 to 50 Volts

and 0 to 50 Amps. Marked pat. appld for, made in

U.S.A. At the bottom there's a circular cutout in the

dial and what looks like a notch where a stylus could be inserted

to set the zero. Both Volts and Amps are operational,

although like the meter above far from what today would be called

calibrated. The glass is broken so needs to be

replaced. The ground lead is attached to the meter and so is

here. The only other ground lead is the meter that came in a

leather case. The lesson seems to be if there's no place to

store an accessory, even a critical one, it will get separated and

that means lost.

Links

There are a couple of people who

make No. 6 battery adapters that make use of "D" cell

batteries. There are thumb screw or

Fahnestock Clip terminals.

Back to Brooke's PRC68, Products for Sale, Battery,

Mil Battery Table, Battery Patents, Flashlights, Leclanché Wet Battery Telegraph, Leclanché

Battery, Electronics, Military Radio, Personal

Home page

[an error occurred while processing this directive] page created on 3 Sep

2007

This is

based on the same concept of using test caps for the ends and PVC

pipe for the tube. I've found a combination of fittings that

allows the user to choose either Fahnestock Clips or thumb screws

(maybe also an option for Wing Nuts which were commonly used in

Europe then you don't need pliers to tighten the thumb nuts.

Ever wonder what those "teeth" on pliers were

for?). Note if you add Fahnestock Clips under the thumb nuts

then you can not depress the clip far enough to insert a tip

pin. Notice there's a tip pin installed in prototype 2.

This is

based on the same concept of using test caps for the ends and PVC

pipe for the tube. I've found a combination of fittings that

allows the user to choose either Fahnestock Clips or thumb screws

(maybe also an option for Wing Nuts which were commonly used in

Europe then you don't need pliers to tighten the thumb nuts.

Ever wonder what those "teeth" on pliers were

for?). Note if you add Fahnestock Clips under the thumb nuts

then you can not depress the clip far enough to insert a tip

pin. Notice there's a tip pin installed in prototype 2.

The

current version of the No. 6 is no longer a Carbon Zinc, but a

post Mercury ban Alkaline. This type of alkaline cell is the

common type on the shelves of all kinds of stores that sell the

common AAA, AA, C, D and 6 Volt lantern and 9 Volt transistor

radio batteries.

The

current version of the No. 6 is no longer a Carbon Zinc, but a

post Mercury ban Alkaline. This type of alkaline cell is the

common type on the shelves of all kinds of stores that sell the

common AAA, AA, C, D and 6 Volt lantern and 9 Volt transistor

radio batteries. The No. 6 battery

that's being sold today is no longer a single cell that's the same

size as the old No. 6, but instead is a plastic shell that holds a

couple of "F" size modern Alkaline cells connected in

parallel. The reason for connecting them in parallel is two

fold.

The No. 6 battery

that's being sold today is no longer a single cell that's the same

size as the old No. 6, but instead is a plastic shell that holds a

couple of "F" size modern Alkaline cells connected in

parallel. The reason for connecting them in parallel is two

fold.

After bending back the metal on

the bottom of this Energizer 6 Volt Lantern Battery (model 529)

the following parts are found:

After bending back the metal on

the bottom of this Energizer 6 Volt Lantern Battery (model 529)

the following parts are found: This is some terminal hardware consisting of:

This is some terminal hardware consisting of: Teeth

on Pliers

Teeth

on Pliers

This is a

modified two D cell battery holder. It normally has solder

lugs on the two ends and no electrical connection to the

frame. By installing three terminals, one on each end and one

on the frame the battery holder can be used to combine two D cells

in series or parallel.

This is a

modified two D cell battery holder. It normally has solder

lugs on the two ends and no electrical connection to the

frame. By installing three terminals, one on each end and one

on the frame the battery holder can be used to combine two D cells

in series or parallel. I ordered these

from my local Interstate Battery store as their Dry1725

expecting it to be made like the Energizer EN6 or military BA-23

using two "F" cells. But it's a real No. 6. They weigh

28.5 oz a lot more than the 16.4 oz for the plastic two "F"

type.

I ordered these

from my local Interstate Battery store as their Dry1725

expecting it to be made like the Energizer EN6 or military BA-23

using two "F" cells. But it's a real No. 6. They weigh

28.5 oz a lot more than the 16.4 oz for the plastic two "F"

type.

15 Dec 2007 This meter arrived DOA.

Once the back was off (Kroil helped when prying the back) the

problem was that a Mica washer was used between the terminal lug

on the end of the green wire and the case as an insulator.

The terminal that screws into the outside has what amounts to a

shoulder washer to keep it from touching the case. Mica is

fragile and the washer had broken. It's inside the back

cover on the right. I just cut a small square of 3 x

5" card and used that on the inside as an insulator as a temporary

fix and the meter is now working.

15 Dec 2007 This meter arrived DOA.

Once the back was off (Kroil helped when prying the back) the

problem was that a Mica washer was used between the terminal lug

on the end of the green wire and the case as an insulator.

The terminal that screws into the outside has what amounts to a

shoulder washer to keep it from touching the case. Mica is

fragile and the washer had broken. It's inside the back

cover on the right. I just cut a small square of 3 x

5" card and used that on the inside as an insulator as a temporary

fix and the meter is now working. The

negative battery terminal connector on the test lead shown at the

left is the same as the batery positive terminal connector on the

bottom of the meter. They have a hollow pocket that allows

holding the connector on top of the threaded terminal on the No. 6

Dry Cell.

The

negative battery terminal connector on the test lead shown at the

left is the same as the batery positive terminal connector on the

bottom of the meter. They have a hollow pocket that allows

holding the connector on top of the threaded terminal on the No. 6

Dry Cell. This

is

a

Voltmeter for checking what were then common battery voltages

which were: 1.5, 3, 4.5 and 6 on the low range and 22.5, 45 and 90

on the high range. Stamped into the case at the bottom

adjacent to the left probe is 90 and adjacent to the right probe

is 7.7. Half way between them is the ground schematic

symbol, meaning a test lead from the top threaded terminal is the

ground connection.

This

is

a

Voltmeter for checking what were then common battery voltages

which were: 1.5, 3, 4.5 and 6 on the low range and 22.5, 45 and 90

on the high range. Stamped into the case at the bottom

adjacent to the left probe is 90 and adjacent to the right probe

is 7.7. Half way between them is the ground schematic

symbol, meaning a test lead from the top threaded terminal is the

ground connection.

0 to 50 Volts

and 0 to 50 Amps. Marked pat. appld for, made in

U.S.A. At the bottom there's a circular cutout in the

dial and what looks like a notch where a stylus could be inserted

to set the zero. Both Volts and Amps are operational,

although like the meter above far from what today would be called

calibrated. The glass is broken so needs to be

replaced. The ground lead is attached to the meter and so is

here. The only other ground lead is the meter that came in a

leather case. The lesson seems to be if there's no place to

store an accessory, even a critical one, it will get separated and

that means lost.

0 to 50 Volts

and 0 to 50 Amps. Marked pat. appld for, made in

U.S.A. At the bottom there's a circular cutout in the

dial and what looks like a notch where a stylus could be inserted

to set the zero. Both Volts and Amps are operational,

although like the meter above far from what today would be called

calibrated. The glass is broken so needs to be

replaced. The ground lead is attached to the meter and so is

here. The only other ground lead is the meter that came in a

leather case. The lesson seems to be if there's no place to

store an accessory, even a critical one, it will get separated and

that means lost.