Capacitors

© Brooke Clarke 2010

Background

Examples of Bad Caps

Super Capacitors

Memory

Industrial/Commercial

Automotive Sound

Measuring the Capacity of a

Super Capacitor

Table

Variable

Related

Links

Background

These were purchased at test

subjects for the

ESR Micro combined

Effective Series Resistance and Capacitance meter. I was

going to put this data on that page but way too large so is here

as a separate page.

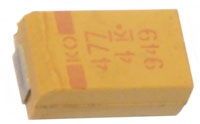

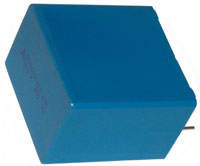

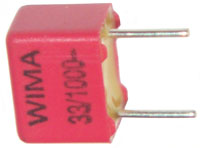

The first choice was to get leaded parts to allow insertion in the

ESR MIcro and the

SR715. Parts

that are a few cents were ordered on tape at 100 each so in some

photos you will see the tape. The photos have been scaled so

they are all 200 pixels wide, so the scale factor varies a lot,

i.e. they are NOT shown in relative size.

The photos will help ID different types of caps. More photos

on the

Capacitor Failure paragraph on

the Hints & Tips web page.

Wiki page

Capacitor

plague about the bad electrolytic caps (

Wiki)

made around 1999 but still being used up to about 2007 and failing

in 2010.

Examples of Bad Caps

These are related to using the

ESR-Cap meter.

This had nearly all the electrolytic caps bad. It's now

working great on the built-in whip antenna.

Oven Controller

See Hints and Tips: Cold Oven

Robertshaw

Controller in GE Electric Oven

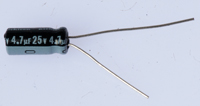

Two caps in the analog temperature control circuitry, both marked

4.7 uF 35 V, tested C: 000 ESR: ---. The interesting thing

is that the replacement caps, rated 4.7 uF 25 V, are larger.

This means the capacitors the factory used were faulty in that you

can't get that much capacitance in that small a package with that

voltage rating.

I didn't determine the working voltage of the 4-bit micro

controller but expect it runs on 5 volts. The LM324 op amp

might be running as high as 32 V, but I very much doubt it, +/- 15

would be the max expected, so getting 25 V replacement caps seems

to be conservative.

|

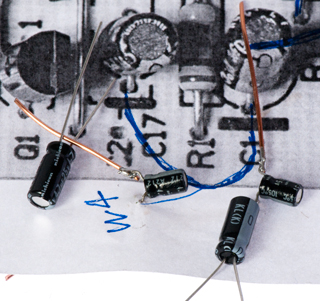

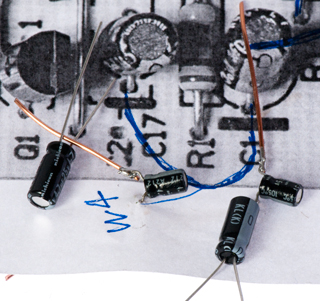

The bad C1 and C17 caps

were punched into a copy of the board photograph to keep

track of them and then bare wires were soldered on to

allow them to fit in the SR LCR meter or HP LCR

fixture. You can see that the new caps are much

bigger.

|

Cap

|

WVDC

|

dia

mm

|

height

mm

|

pitch

mm

|

Old

|

4.7

|

35

|

4

|

6

|

1.5

|

New

|

4.7

|

25

|

5

|

11

|

2

|

The height needs to be short in order to allow for the

relay board that's mounted directly above this board (see

the Hints and Tips web page).

The replacement parts were installed laying on their sides

out of general principles. But it turned out

it was required for vertical clearnace.

The volume of an electrylytic capacitor depends on both

the capacitance and on the working voltage and since the

new part has a lower working voltage there's a huge

difference in volume.

|

The SR 715 (1 kHz & 1V drive) shows the bad caps as about 20

nF (0.02 uF) not the 4.7 uF they should be and with a series

resistance of about 40 k Ohms. This is consistant with the

electrolyte evaporating. Note that total hours of use this

oven has seen is probably under 10 so the problem was not

heat. But the controler board (clock) is powered 24/7/365

minus the occasional power failure.

Super Capacitors

There are three general types of super capacitors (Wiki: Capacitor).

They are also known as Double Layer Capacitors (Wiki)

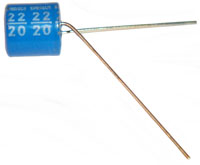

Memory Hold Up Super Caps

These typically have an internal resistance that's 10 or more

Ohms. Because of the high internal resistance they're

good for very low current applications, but can not be used

for powering motors or other high energy applications.

See 24 and 25 below.

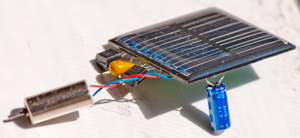

Commercial/Industrial Super Caps

These are typically single units and so have a breakdown

voltage under three volts.

Measuring (see below) a 20 Farad 2.7

Volt capacitor by setting the HP E3617A bench top power supply

for 2.5 Volts (below the 2.7 V max) and with the clip leads

shorted setting the current to 0.5 Amps.

Connecting the second clip lead when the clock is at the top

of a minute (23:32:00) and watching the voltage on the power

supply climb.

It gets to 2.0 volts at 23:33:25, i.e. after 85 seconds.

So the total Coulombs moved is I (Amp)* t (sec)= 0.5A * 85

seconds = 42.5 CoulC = Q / V = 42.5 Coul / 2 Volts = 21.25

Farads

Automotive Audio Super Caps

These start at about 1 Farad and are rated for "12 Volt"

automotive electrical systems and so can be charged.

The built-in voltmeter shows Lo from about 5 volts to 8.34 Volts

then shows the voltage up to 15.9 Volts, and above that shows

Hi.

The meter draws 17 ma at 16 volts, which is a large part of 100

ma, which I'm using to measure the capacitance, so for measuring

the capacitance it's best to remove the meter.

It's probably also a good idea for automotive users to remove the

voltmeter so that the battery will hold it's charge for a longer

time. With the voltmeter connected the cap drains very

quickly, but without the meter the battery takes a few days to

discharge to 9 Volts. If the cap discharges too far it may

blow a fuse in an automotive application.

|

1 Farad Cap

with Voltmeter removed

|

|

|

Measuring the Capacity of a Super

Capacitor

The method is known as Coulomb (Wiki) counting

and is commonly used to measure battery State Of Charge (Wiki: SOC

Coulomb counting).

For example for the 1 Farad Truconnex super capacitor above I

started with the terminals shorted for a little while so the

voltage was zero.

Then setup an HP/Agilent E3617A bench top power supply for 16.0

Volts open circuit and with the leads shorted together set the

current to 100 mA.

At the top of a minute I connected the power supply to the super

capacitor and watched the voltage meter on the supply climb up to

14 Volts and noted the time again (it was right at 2 minutes.

The number of coulombs delivered to the capacitor is 0.1 Amps *

120 Seconds = 12 coulombs

Note: The reason for using a current source rather than a

common power supply that's close to a constant voltage source is

that if a voltage source is used the current will be constantly

changing to reflect the voltage difference between the fixed

power supply voltage and the increasing capacitor voltage.

That makes it very hard to count the charge transfer (coulombs).

C = Q / V = 12 coul / 14 V = 0.857 Farad

Plotting in Excell the time vs. voltage and fitting a straight

line that goes through 0, 0 gives the following slope &

quality of fit:

Volts on the Y axis and Seconds on the X axis.

C = dQ / dV

dQ is the change in one second and since the current is 0.1 Amp

that's 0.1 coulomb.

dV is the slope of the line and that's 0.0776 so:

C = 0.1 / 0.0776 = 1.288 Farads

This may be a little more accurate than basing the capacitance

on a single measurement, like above.

There is a little curvature in the actual data compared to the

straight line, not sure why.

Next try this with a different current to see if it results in

a similar answer.

Table

Tested in # order using all the

testers, then the next #. A Lazy Susan helped.

SR 715 at

left then counter clockwise

Micro ESR-Cap

meter,

EVB ESR (only) meter, Fluke

87

DMM

Note 1 The Fluke 87 has trouble

measuring the capacitance of parts in the pf range because it's

difficult to get a repeatable delta to zero the meter. A

plug in axial capacitor fixture might solve that problem.

Note 2 the Stanford Research 715 is fixtured for axial lead parts

only, SMT and supercaps do not fit.

Note 3 Multi Layer Ceramic Caps (MLCC) have frequency dependent

capacitance and series resistance on the SR 715.

Note 4 FRS is

Fair Radio Sales

Note 5 Leakage at 50 V (after soaking a minute) for

Cap30

Variable

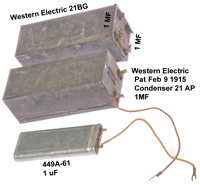

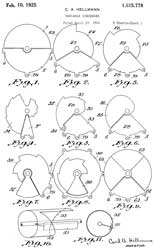

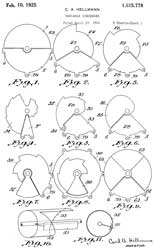

After a quick look at old patents I found this one where the

capacity is not a linear function of tuning shaft angle.

This is aimed at crystal radios.

A variable condenser used for transmitting must have extremely

low series resistance which is not required for crystal radio

use.

Looking for design info for rotor plates for linear AM radio

dial frequency.

|

|

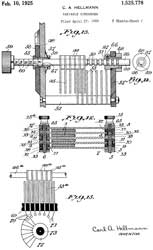

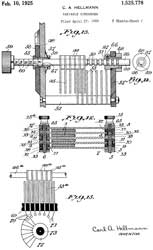

1525778

Variable condenser, Carl

A Hellmann, 1925-02-10, -

Fig 1. prior art linear & 180 deg rotation.

Fig 2. 240 deg useful range

Fig 3. 270 deg useful range

Fig 4. useful range of 360 deg * n/(n+1)

Fig 5 & 6. >180 deg range & non linear

Fig 7. rotor smaller angular extent than stator

Fig 8. like Fig 7 but different arrangement

Fig 9. >180 deg range

Fig 10 & 11. Cylindrical layout

Fig 12. movable dielectric w/fixed paltes

Fig 13. axial shift to change range

Fig 14. detail for Fig 13.

Fig 15. electrical detail for Fig 13.

1748345

Rotary variable condenser, Carl

A Hellmann, 1930-02-25, - similar.

|

|

|

1609006

Variable condenser, Clarence

D Tuska, CD

Tuska Co, 1926-11-30, -

bearing alignment

|

|

|

1709959

Variable condenser, John

W Simmons, RCA,

1929-04-23, -

rigid, fine adjustment,

|

|

|

2123050

Variable capacitor, Marwin

R Johnson, GE,

1938-07-05, -

slotted end plates to allow tweaking capacitance

curve.

|

1525778

Variable condenser, Carl

A Hellmann, 1925-02-10, -

Related

Links

Back to Brooke's Home,

Test Equipment, Products for Sale,

Military Information

web pages.

[an error occurred while processing this directive] Page created 11 Mar

2010.