1929 & 1934 Rolls Royce

© Brooke Clarke 2016 - 2019RAC Horsepower

Steering Column Rake

Description

Firewall

Bijur chassis lubrication

Trafficators

Starting

Hand Crank

Electric Starter

Starting on the switch

Pushing

Parking Pointing Down Hill

1929 Phantom II

1934 20/25

Photos

20/25

Phantom II

Side Note on V8 Rolls Royce Cars

Related

References

Links

Background

My son came across some photos I had taken shortly after importing a couple of Rolls Royce cars from the UK. I drove them home from the U.S. customs car lot in Oakland on the 880 freeway, but going less than 55 in the slow lane. So this page has those scanned photos.

In the late 1960s I wanted to go to the UK and find a Rolls Royce Silver Cloud (Wiki). When I got there I was too late and they were pretty much gone. At Coys of Kensington in London I asked for an older Rolls Royce that could be driven. They took me to a garage that was one or two car wide and 6 cars deep with the 1934 20/25 (20 Horse Power that you paid tax on but 25 horse power on the dynamometer) owner driver car at the back, so they would need to remove the other cars for a test drive. But on the way to see the 25/25 on of the cars in front of it was the 1929 RR 40/50 Phantom II truck. So I asked to see both of them the next day.

RAC Horsepower

The Royal Auto Club Horsepower (Wiki) HP = (2 * D * D * n)/5

So for a 6 cylinder engine with RAC HP = 20 the piston diameter may be 2.887" (2-7/8") but manual says 3-1/4" bore x 4-1/2" stroke (224 cu in)

For a 6 cylinder engine with RAC HP = 40 the piston diameter may be 4.082" (4-1/16") but manual says 4-1/4" bore x 5-1/2" stroke (468 cu in)

Steering Column Rake

A chassis design parameter is the angle the steering column makes with the ground.

A shallow column rake means the steering wheel is nearly in a vertical plane and is comfortable for an owner driver.

A steep column rake means the steering wheel is nearly horizontal, like in a truck or chauffeured car.

Description

Both cars have a number of common features.

Firewall

The firewall is an aluminum casting, not sheet metal like the newer cars.

Bijur chassis lubrication

A chassis lubrication system is fitted which automatically lubes almost all the points that need it.

Still in business.

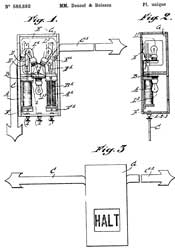

Trafficators (Wiki)

Turn signals.

Figures 1 to 3 shown in the operational orientation.

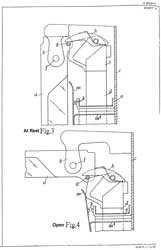

It turns out if you try to open the arm it will not move because there's an over center mechanism locking in in the at rest position.

In order to open the electromagnet need to pull the mechanism enough to unlock it.

Someone has put a small piece of cardboard between the two additional coil contacts and that's probably decreasing the coil current enough to prevent the mechanism from working. Tomorrow I'll try shorting those contacts.

FR586880 Indicateur de direction à commande électrique pour automobiles et autres véhicules, Gustave-Pierre Deneef, Maurice-Jules-Abel Boisson, 1925-04-04, -

GB431699 Electric switches for controlling direction indicators on motor vehicles, , Joseph Lucas, 1935-07-15, -

Mounted on the steering column so that turning the steering wheel will cancel the signal.

GB458796 electric switches for controlling road vehicle direction indicators, Joseph Lucas,1936-12-28, -

GB609568 Vehicle direction indicators, Joseph Lucas, 1948-10-04, -

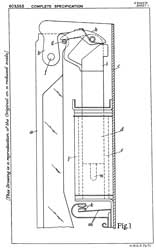

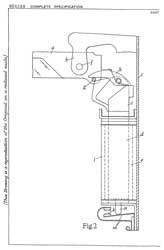

Fig 1. Arm pivots at (f) and has pin (g) nearby. Sprint loaded are arm (h) presses on pin (g) when are is in closed position and locks it closed.

Electromagnet main winding: e

Electromagnet additional winding: j shorted out at start but opens when fully open to lower current.

In Fig 3 & 4 a bi-metal strip replaces the mechanical contacts (k).

electromagnet core: d

The example I have is more complex than this.

Starting

There are a number of ways to start these Rolls Royce cars.

Hand Crank

Both cars have a hand crank that could be used in an emergency.

Electric Starter

Push button is not related to key or on/off switch.

"starting on the Switch"

This method does not drain the battery since it does not use the electric starter.

Both cars have a spark advance control at the center of the steering wheel both to facilitate good running no matter what grade of gasoline you buy but also for "starting on the Switch". RR (and probably others) had a feature related to the manual spark timing lever. When you were about to turn off the engine, you first put the advance lever all the way up, then turned off the ignition switch (the key was separate from the switch). In this way the engine would turn over maybe a turn or two with no spark and in the process inhale some fresh air and gas. When you wanted to start the car, after shopping or whatever, you would turn on the ignition switch and then move the advance level smartly down. This would cause the points to open and fire whichever cylinder was just past top dead center, starting the engine without cranking. I got this to work, but not all the time.

1912 Cadillac brochure - reprinted in 1973 - (1912_Cadillac_VVI.pdf), pdf pg 16 "In fact the Cadillac engine so frequently starts by the spark that the use of the electrical starter is not always required"

Pushing

This is a time honored method, but only works with manual transmissions, which both of these cars have.

Parking Pointing Down Hill

This only works if you have a parking spot that's suitable. I've seen it in some movies, not not real life.

1929 Phantom II

In 1929 Charles Rolls (Wiki) was already dead from crashing his Wright Flyer (Wiki) airplane after making an "improvement". But Henry Royce (Wiki) was very much alive and overseeing the quality of the chassis. So the RR at the top center of the radiator is red. After Royce died in 1933 the RR was black and stayed that way until 1983, after 50 years in morning, the RR was again red. The 1929 is made of almost 100% Rolls Royce manufactured parts.

This chassis (serial 14WJ) was the back-up car for the Earl's Court Motor Show to introduce the Phantom II with the sub frame (Wiki). Prior to the use of a sub frame Rolls Royce would build the chassis to order (Wiki: bespoke) then the chassis would be sent to the coachbuilder (Wiki) (note: Rolls Royce did not make cars then, they only made the chassis). The original product of a coachbuilder was a horse drawn vehicle. When motor vehicles came out it was only natural that you would get a chassis from the automobile maker and commission a coachbuilder to make a custom body.

Starting in 1929 the sub frame could be sent to the coachbuilder while the chassis was being manufactured so that total time to get a running car would be much shorter.

Steering shaft rake angle is one of the things that can be customized. If a Chauffeur (Wiki) is going to drive the car than a steep angle would be used so that the steering wheel is closer to horizontal. That makes more room in the rear seat. But for owner driver cars the rake angle would be lower so the steering wheel is closer to vertical. AFAICR 14WJ has the "F" angle.

Because of the very high reliability of the Phantom II it was a common practice that when the coachwork got out of style it was removed and some other coachwork installed. In this case a panel delivery truck body was used. The earlier version of the Phantom II was used to make the Rolls Royce Armored Car (Wiki).

My son had a look at this web page (he has these cars now) and had these comments:

I believe the PII is the last car that Royce designed. Also, I would note the PII was mostly made of RR parts in 1929, but not exclusively. The magneto is made by Watford and the vacuum tank says Autovac (Wiki, Home page, GB424299, GB424299) if I remember correctly. I think there are a number of parts that RR got from suppliers. However, the clutch and carburetor were made by RR in 1929. In later years, the PII adopted an outsourced carburetor (SU (Wiki) if memory serves) and a Borg and Beck (Wiki) clutch. The 20/25 has far more outsourced parts.

I believe RR also made the Dynamos (Wiki). Royce actually started out making dynamos before he made cars. His electrical experience contributed to the reliability.

Another interesting feature is the brake system. RR actually bought rights to build it from Hispano-Suiza (Wiki). It uses a servo clutch that runs off the transmission driven by the rotation of the rear wheels. Applying the brake pedal activates the clutch and applies power to the brakes. When the car is moving slowly, it takes a couple feet of movement for the clutch to actuate the brake cables which gives an unusual braking feel.1934 20/25

This is a small owner driver Rolls Royce called the 20/25 (Wiki). This car has a black RR since it was made shortly after Royce died. Some of the parts were manufactured by an outside supplier. Note 20/25 is half of 40/50.

Photos

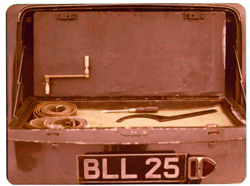

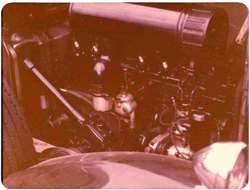

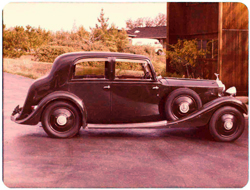

1934 20/25 Rolls Royce license BLL25, chassis No. GWE72

Fig 2 Boot (trunk) with engine crank and

luggage tie down belts

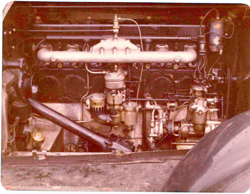

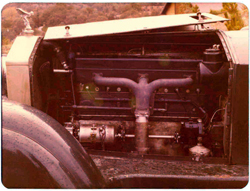

Fig 3 engine

Fig 4 engine

Fig 5 Rear, tail lights are different than

Trafficators (Wiki).

Fig 6 Fitted set of tools for all (routine?) maint.

Fig 7 Front (Bob's house across the street)

Fig 8 Side, Trafficator (Wiki) between front and read doors.

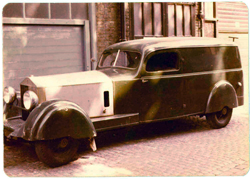

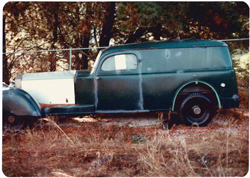

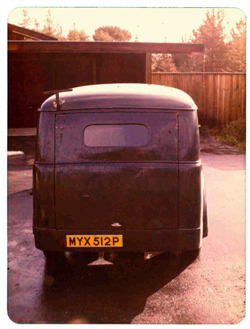

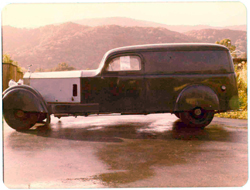

1929 40/50 Rolls Royce license: MYX512P, chassis No. 14WJ

This was the standby chassis for the Earls Court motor show introducing the Phantom II which has a sub frame so that the coach builder can be working on the body while the chassis is being made by Rolls Royce. At that time Rolls Royce did not sell complete cars, they only sold the chassis.

The gas gauge Fig 13 seems very similar to the 1932 Kollsman patent. To operate you work the pump and then the fluid in the sight glass shows the fluid level in the gas tank.

Fig 1 Taken in London at Coy's

Fig 2 Side

Fig 3 Engine

Fig 4 Engine

Fig 5 Rear

Fig 6 Spare tire

Fig 7 Taken in London at Coy's

Fig 8 Front

Fig 9 Side

Fig 10 Side

Fig 11 Instrument Panel

Fig 12 Steering wheel

Fig 13 Instrument oanel

Fig 14 Engine

Fig 15 South Side of house

With long skylight (and Sundial Analemma)

Side Note on V8 Rolls Royce Cars

In the early 1970s I got a 1969 Bentley T-series car (Wiki).

Unlike these older cars that have an in-line 6-cylinder engine

the T-series Bentley and the Silver Shadow RR (Wiki)

have a V8 engine. By the time the Silver Shadow and

T-series cars (identical in all ways except all the Rolls

Royce markings have been replaced by Bentley markings) were

designed and manufactured, a great majority of the parts were

outsourced. When a problem occurred a patch would be

applied. Over the years there were patches on top of

patches and the overall reliability of the car decreased.

O-Rings between engine block and cylinder sleeves

The V8 engine is made from an aluminum block with steel

cylinder liners sealed with 3 O-rings. One at the top

and two at the bottom. The very bottom O-ring seals the

crankcase oil from going up and if it leaks oil will drip out

of the weep hole between the two lower O-rings. If the

bottom upper O-ring leaks water will come out of the weep

hole. But in either case the fix is to take apart the

engine including pulling all the pistons and sleeves then

installing new O-rings. The problem is that any water

leak will cause the engine to overheat damaging some or all of

the O-rings and a huge expense. I'd say all V8 RR

engines are a POS (Wiki).

After a crack appeared in the aluminum block between the

upper and lower O-rings I hired a local R&D welder to fix

it. But he could not because the aluminum was

impregnated with plastic to fill up any pores making it

impossible to weld. (Maybe I could have fixed it using

epoxy?)

Water Pump Seal

Another interesting problem revolved around the water pump

seal. The pump impeller has a flat near the center that

maybe a couple of inches in diameter. This needs to be

sealed water tight to the stationary pump housing. This

is a common thing for a water pump of any kind. But, the

seal on the Bentley V8 water pump had a design defect.

It was made up of a carbon flat washer that is pressed against

the flat on the impeller by a spring. Between the carbon

washer and the other end of the seal was a spring, similar to

a valve spring. The problem is that any friction between

the rotating impeller and the carbon washer puts torque on the

spring and rubber boot. If that torque varies the spring

and rubber boot are twisted back and forth while hot water

under pressure press against the rubber which is bio

degradable (like the rubber O-rings between the cylinder

sleeves and the engine block). This flexing causes the

rubber boot to rip letting the cooling water be pumped out of

the engine. It turned out that there was an after market

replacement seal that incorporated a couple of metal cylinders

with a large notch and mating finger that both resisted the

torque thus preventing rotation of the rubber boot but also

providing only a very small gap for water to flow when the

rubber does bio degrade minimizing the volume of water that

flows out of the engine.

Related

Cars -

HMMWV

M151

3 Wheel Recumbent Electric Bikes

Aircraft

Submarines - Torpedoes - Sonobuoys

TTW - Tilting Three Wheelers

References

Links

PRC68, Alphanumeric Index of Web pages, Contact, Products for Sale

Page Created 26 July 2016