19" Rack Mount Equipment

© Brooke Clarke

2002 - 2023

Background

Horizontal Standards

Vertical Standards

Sub Modular

Depth Standards

Access

Stacking Instruments

Accessories

Safety

Shipping

Reusable Pallet &

Cardboard Box

Van with Power Lift

Portable Crate-Rite Rack

Mount Case

Fast Pack

Examples

HP Instrument Serial Number & Date Code

Air Transport Rack (ATR)

LackRack

Related

Links

Background

In the late 1800s when common battery telephone systems

were introduced the 19" rack was born. It's not clear if

this was the exact standard we have now. Later in telephone

service there was a need for wider racks but these maintained the

hole spacing now used on 19" racks.

It may have been in the 1930s and 1940s that the current standard

was established, see

here.

The specification is EIA-310-C "Racks, panels, and associated

Equipment".

There's also IEC 60297 Mechanics for Racks - 19 inch common

standard (DIN41494}.

Early on HP recognized that many of it's customers were mounting

their test equipment into 19" "relay racks". This is a

practical way to build a test system for many reasons. If a

test equipment manufacturer does not allow for this they are

eliminating sales.

Almost all "bench" instruments are designed to also allow rack

mounting. This may require removing the bench feet, carry

handle, rubber bezel or other enclosure parts and the addition of

a rack mount kit that typically contains the "ears" and other

hardware.

Horizontal standards

The space between the two vertical rack mount attaching

rails is 17 3/4". Any equipment that's rack mounted must be

narrower than this. The horizontal distance across the "rack

mount ears" on the equipment is 19". Instruments could be a

fraction of a rack width. The HP/Agilent 4395A Spectrum/Network/Impedance

Analyzer and the HP 54501A Digital Oscilloscope are 16 3/4" wide

and are full width instruments. The HP/Agilent 34401A Multimeter

is 8 1/4" wide and is 1/2 rack width. The HP 204 Audio Oscillator, HP 432 Power Meter and the 427A Voltmeter are all 5 1/8" wide or

1/3 rack instruments.

10-32 tapped holes 18.3" center to center on verticals.

There are mounting kits for all rack standard sizes of

instruments

|

Rack Width

|

Instrument width

|

|

full

|

16 3/4 (< 17.75)

|

|

1/2

|

8 1/4

|

|

1/3

|

5 1/8

|

|

1/4

|

3 5/8 ?

|

Vertical Standards

The screw holes

in the rack are not all on the same center to center spacing, but

rather are repeating between 0.5", 0.625" and 0.625". This

works with a set of standardized panel heights that are all

multiples of 1 3/4" which is called 1 Unit high. All rack

mount equipment is an integer multiple of 1 Unit. The

location of the notches that pass the 10-32 mounting screws is

standardized for each panel height. Note that the location

of the notches is vertically symmetrical allowing the equipment to

be installed right side up or upside down.

The screw holes

in the rack are not all on the same center to center spacing, but

rather are repeating between 0.5", 0.625" and 0.625". This

works with a set of standardized panel heights that are all

multiples of 1 3/4" which is called 1 Unit high. All rack

mount equipment is an integer multiple of 1 Unit. The

location of the notches that pass the 10-32 mounting screws is

standardized for each panel height. Note that the location

of the notches is vertically symmetrical allowing the equipment to

be installed right side up or upside down.

1/2"- 5/8" - 5/8" repeating.

RU is from center of space in 1/2" gap

22 May 2008 - while trying to fit the FTS4060 into

a rack it appeared that the notches were in the wrong place.

But before cutting metal a through analysis of how panels can be

notched followed.

There are two

ways that the holes can be located in a panel. One way is to

have the edge of the panel centered between two holes that are

1/2" apart. The other way is to locate the holes so the

panel edge is centered between two holes 5/8" apart. Note

that the sum of the three cyclic hole spacings is 1.75" i.e. the

1U pitch. Because of that if one edge of a panel that is an

integer number of units high then the other edge will fall between

holes of the same pitch. The half the distance between two

holes 1/2" apart is 1/4" or 0.250 which is a nicer number than

half of 5/8" i.e. 5/16 or 0.3125" most panels center the edge on

the 1/2" holes.

Note:

If all the panels in a rack have been made on 1/2" or all

on 5/8" edges then they will stack one panel right next to

the one next to it. BUT, if you have two different

edge spacings then there will be a wider gap between

adjacent panels with different edge location layouts.

|

The holes are symmetrical top to bottom allowing for

installing a panel upside down.

When installing a panel the bottom two holes carry virtually all

of the torque that's trying to let the center of gravity of the

instrument rotate downward. If you install the bottom two

screws they will hold the instrument. But if you install

only the top two screws the bottom edge of the instrument will

tend to move away from the panel and if a heavy instrument may

break free. The loading on the bottom screws is minimized if

they are as far apart as possible. That's more important

than having more screws.

|

Units

|

Height inches

|

Edge centered on 1/2"

Notches from top inches |

Edge

centered on 5/8"

Notches from top inches |

|

1

|

1.75

|

1/4 1 1/2

|

5/16, 1 7/16

|

|

2

|

3.50

|

1/4 3 14

|

|

|

3

|

5.25

|

1 1/2 3 3/4 |

|

|

4

|

7.00

|

1 1/2 5 1/2 |

|

|

5

|

8.75

|

1 1/4 3 5 3/4 7 1/2 (4 holes)

1

or

1 3/4 4 3/8 5 (3 holes)

|

|

|

6

|

10.50

|

1.75, 3.34, 6.75, 8.75 |

|

|

etc.

|

etc.

|

etc.

|

|

Note 1 - corrected error 22 May 2008

Racks come in a number of heights from table top units to ones

that are just a little too tall to go through some door you need

to go through. When this happens it may be easier to take

apart the door frame than it is to take apart the rack loaded

with equipment. Some are just bare frames and others are

very fancy.

Sub Modular

HP made a number of instruments they called Sub Modular.

They are all 6 3/32" high.

They can be combined into a rack size using the 5060-0797 Adapter

Frame. When this is used it is not easy to add or remove

instruments.

They can also be easily combined using the Model 1051A Combining

Case. This case has flexible plastic retainers that can be

easily opened to allow an instrument to be installed or removed.

These retainers can also be moved horizontally to allow different

combinations of instruments to be installed. It will hold

three instruments that are 5 1/8" wide, which was a very popular

size.

Depth Standards

I'm not aware of any standards about depth.

Access

It may be important that someone can

get to the back and/or sides of the rack. In other cases a

rack can be pushed back against a wall.

This is something that needs some thought when the space is being

laid out. While working on a system it's best if the rack is

in the center of a room so you have access to all sides.

Stacking Instruments

Many of the HP instruments have a groove running left -

right along the top and the front bench feet have a tongue that

will fit into the groove of an instrument that was stacked below

it. The groove ends about 1/4" before each side so when

instruments are stacked they are interlocked both front to back

and side to side.

Instruments that do not have this feature tend to slide off the

instrument below them when you are connecting cables or

otherwise pushing on them. They typically don't make it to

the floor, but tend to stop after the feet are off the

instrument below them.

The term Rack and Stack is used to

describe the ability of combining instruments in an organized

manner and that's why I chose it as the name for my business of

building this type of system.

Accessories

|

Outlet strip at right.

Just left of outlet strip are rear vertical rails.

Note ground pin up so that if something falls it will hit

ground rather than hot.

L-rail supporting instrument at top center.

Blue shelf supporting some Gel-Cell batteries.

|

Rails

Many racks built to hold electronic equipment also have a pair of

vertical rack mounting rails in the back. The most common

use of these is to install a couple of "L" section bars front to

back to act as a shelf to hold heavy equipment as it is slid into

and out of the rack. This makes is much easier to work with

heavy boxes.

These is also a way to get equipment into a rack that does not

have "ears" using a shelf, but the rack can not be shipped

because the equipment is not attached to the rack. Also

not good if in Earthquake country.

The rear vertical rack mount feature can be used to mount

equipment from the back side. If there is a front panel on

the equipment you typically want that facing forward, but if you

want to have a place to mount a lot of connectors, then

installing a panel on the back is great. Also AC power

entry panels and fans.

Blank Panels

Are used to fill up empty space both for appearance and in systems

where forced air cooling is used.

Outlet Strips

Mounted vertically at the rear of the rack provide a place to plug

in all the equipment. Two may be required if there's a lot

of equipment in the rack.

A comment on outlet strips in general. With

older tube equipment the spacing of "Plug

Mould" type outlet strips was many inches. These

could be mounted to a work bench and provided maybe one outlet

every 6 inches. This was OK when using tube equipment

because of the 15 Amp limitation on a single AC circuit.

With modern solid state equipment that draws very little current

you need as many outlets as you can get on the strip.

On older strips the sockets are arranged with the flats aligned

along the long axis of the strip. When a "wall wart"

transformer or power supply is plugged into this type of strip

it will cover one or two of the adjacent sockets. The

latest power strips turn the sockets so the flats are at right

angles to the long axis so that "wall warts" will go off to the

side. They also space the sockets to allow for this, or

maybe allow for one or two wall warts. You can also get

short "Y" cables for connecting wall warts to outlet strips.

Note ground pin up so that if something falls it will hit ground

rather than hot.

On-Off Switch

It's convenient to have a single On-Off switch for the whole

rack. That way you know the rack is turned off. Some

instruments do not have lights so without careful inspection you

don't know of they are on or off.

Power Panel

With older tube type equipment the power consumption of the total

rack typically exceeded the 15 Amp limit for a single A.C. power

cord so the rack might have a power panel that would take in 220

VAC, provide a main circuit breaker and feed the rest of the rack.

Fans

These were popular with tube equipment and could be mounted at the

bottom of the rack to blow the hot air out the top.

Custom Rack Kits

There are custom rack kits that are made to mount equipment that

does not readily take rack ears. For example a receiver that

was made to non standard dimensions or a computer monitor.

Keyboard Support

There are special 1 unit high supports for computer keyboards

Table

This is a table that sticks out the front and can be used to

support the unit under test, for a writing surface, etc.

Some can be extended.

Slides

These allow equipment to be easily pulled out of the rack and

sometimes rotated while out. Very handy for maintenance

and troubleshooting.

Safety

A rack loaded with equipment is very heavy. In

movies there's a murder where the victim dies when a bookcase full

of books is pushed over. If a rack is tipped it does not

need to go far in order for the center of mass to move outside the

base outline at which point it will be unstable and fall.

This is a real problem when slides are used. The center of

mass can easily get outside the base area and cause the rack to

fall forward.

I have an HP double wide rack which is on a base plate that

extends the base area forward so that slides can be used without

tipping over the rack.

Shipping

Reusable Pallet & Cardboard

Box

Agilent has a standardized way to ship a rack. It

is placed on a wooden pallet to allow a fork lift to move it.

Inside there is a wooden ramp that's hinged so that the rack can

be unloaded and reloaded onto the pallet. The cardboard side

and top covers are reusable and are attached using reusable straps

(as long as the straps are not cut).

Van with Power Lift

When I worked at Aertech HP

brought one of the first automated Network

Analyzer systems to our plant in Mountain View for a

demonstration. They had modified a panel truck so that the

rack was grabbed on the sides (about at the center of mass) and

could be lifted and rotated to slide into the truck, much like a

casket. This system used a 2116 HP computer with core

memory. At lunch the sales rep loaded a football game

where each player would pick a play: short run, long run, short

pass, long pass or field goal. The probability of the play

working was based on historical Cal vs. Stanford games,

the field position, down and some randomness. Good for

Monday morning quarterbacks.

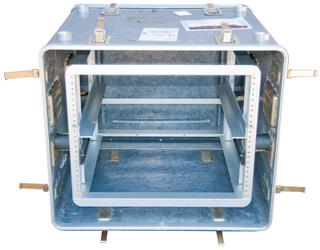

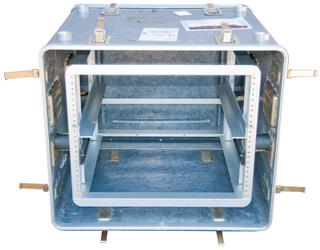

Portable Crate-Rite Rack Mount Case

These provide a way to ship rack mount equipment that can be

reused and take up much less space than cardboard boxes.

This is a shipping case for rack mount electronic equipment.

There's a little more than 14" (8 rack units) height available.

It came with two installed "L" brackets (at about the center)

and four loose "L" brackets.

Also installed just below the "L" brackets are a pair of

equipment slides, but not the mating parts for the slides.

It appears that the two installed "L" brackets were holding a

piece of equipment between the bottom rails and the "L"

brackets, thus taking a lot of the load off the equipment

slides.

It sounds like a good idea to restrain equipment using the "L"

brackets at the top and bottom so that all the load is not taken

by front panel screws.

The equipment holes are not tapped and are oversize for a 10-32

screw. Clip-on metal nuts are installed where front panel

mounting screws will be used.

I've seen a PRC-138 radio and it's

associated power amplifier installed in a similar case, ready to

use.

Marked Manufactured by

Environmental Container

Systems

|

|

Clip for front mounting with 10-32 screws

Tell me where to get

|

Bottom Foot that mates with cylindrical

socket on top of another unit to allow stacking.

|

Spring backed 10-32 T-Nut to be used with

"L" brackets

|

|

From ECScase.com

10-32 screws not included.

p/n: 47001440 Spring Backed T-Nut

p/n: 47001013 10-32 Nut with Clip

|

|

3482895

Protective Case for Electronic Instruments, Dennis M. Becklin,

Crate-Rite Inc., Dec 9, 1969, 312/352; 206/305; 206/594;

220/4.02; 361/730

The inner equipment rack is connected to the shipping shell with

shock mounts. Two or more cases can be stacked vertically

using the locating cylinders.

That way the equipment can be used while mounted in the case

just be removing the front and rear covers.

Fast Pack

There are a large selection of cardboard boxes lined with foam

designed to ship items with excellent packaging easily called Fast Pack. I've received them

in sizes from a book (GPS receiver) to pretty large holding rack equipment. These are

reusable.

Examples

Racks are also a good way to store rack size equipment.

Rack 1 - although you can not

see it in the photos two of these racks are side by side on a

common base with wheels

Rack 2 -

Time & Frequency Rack -

CEI - prior owner

of rack named it: TOBOR RADAR ROBOT (Wiki: Palindrome#Sentences

and phrases)

Racks are currently being used, they are not by any means out of

date. The Agilent E5022 Hard Disk Drive

Functional Test System and the Large Signal Network

Analyzer are both single rack systems I worked with as late as

2000. Many of the automated test systems I

built were in one or two racks.

Air Transport Rack (ATR)

When equipment is rack mounted in aircraft the ARINC 404 (Wiki)

specification governs the system.

ATR Size

|

Width

inches

|

Length

inches |

Dwarf

|

2.25

|

12.62

|

| 1/4 Short |

2.25 |

12.62

|

| 1/4 Long |

19.62 |

| 1/2 short |

4.88 |

12.62

|

| 1/2 Long |

19.62 |

| 3/4 Short |

7.50 |

12.62 |

| 3/4 Long |

19.62 |

| 1 Short |

10.12

|

12.62 |

| 1 Long |

19.62 |

1-1/2

|

15.38

|

19.62

|

An example of an ARINC 404 ATR is the one for the Collins PN-101 Pictorial

Navigation System, see Fig. 10

PS ARINC seems to have a problem with their math.

The 3/4 size is exactly 3 times the 1/4 size. But the other ratios

do not show integer relationships.

10.12 * 0.75 = 7.590 not 7.5

10.12 * 0.5 = 5.060 not 4.88

10.12 * 1.5 = 15.18 not 15.38

If you know why this is let me know.

LackRack

The wood Ikea

LACK side table is 22" square ($13 May 2022) and can be used

to mount rack equipment, i.e. the LackRack.

Related

Time & Frequency

Rack -

Rack 1 -

Rack 2 -

CEI Tempest Receiving

System - I rack named "TOBOR RADAR ROBOT" (Wiki: Palindrome)

Office Equipment

- not in rack, but rack type equipment that is just stacked.

Links

NovexComm

- makes rack mounting kits for a number of popular radios

Cooper B-Line

- 2 post network equipment racks

Bud Ind -

Hammond Mfg -

Knürr -

RackSonic - carries 19" to 23"

rack adapter ears

Back to Brooke's PRC68, Alphanumeric Index of web pages, Products for Sale, Military Test Equipment, Microwave Test equipment, Military Information, Personal Home page

Page created 29 Aug 2002.

The screw holes

in the rack are not all on the same center to center spacing, but

rather are repeating between 0.5", 0.625" and 0.625". This

works with a set of standardized panel heights that are all

multiples of 1 3/4" which is called 1 Unit high. All rack

mount equipment is an integer multiple of 1 Unit. The

location of the notches that pass the 10-32 mounting screws is

standardized for each panel height. Note that the location

of the notches is vertically symmetrical allowing the equipment to

be installed right side up or upside down.

The screw holes

in the rack are not all on the same center to center spacing, but

rather are repeating between 0.5", 0.625" and 0.625". This

works with a set of standardized panel heights that are all

multiples of 1 3/4" which is called 1 Unit high. All rack

mount equipment is an integer multiple of 1 Unit. The

location of the notches that pass the 10-32 mounting screws is

standardized for each panel height. Note that the location

of the notches is vertically symmetrical allowing the equipment to

be installed right side up or upside down.