8" Mini Shear Break

© Brooke Clarke 2006

Description

Shear

Missing Accessory

Guide

Shear Blades

Break

Upper Dies

Lower Die

Applications

Hints

What goes Wrong

Suggested Improvements

Sample Sheet Metal Packs

Phosphorous Bronze

Tin Snips

Brooke's other Metal Working web pages

Links

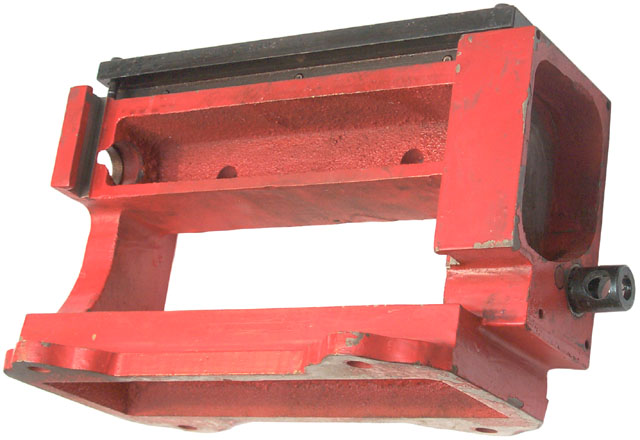

Description

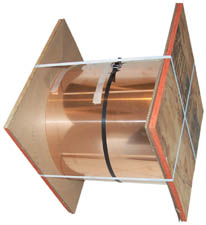

This is a combined 8" sheet

metal shear

and an 8" bending break. It's sold by Harbor Freight as

their SKU

number 90757

and by Northern

Tool

+ Equipment as Item

#

143361. The Harbor Freight version is painted red

and the

Northern Tool version is painted blue, but otherwise they seem

to be

the same. The Micro-Mark 83213

is painted White and includes the cutoff guide (Missing

Accessory on

the other two versions). The Micro-Mark Manual

has some different information from the Harbor Freight manual.

This may also be called a pan and box break because it can bend metal that already has prior bends. Also called a press break, which is different than the folding type of break. The Harbor Freight 18" break 39103 is similar to a flat table top with a hinge. To use it you need to trap the metal using the supplied bar with C clamps then pull up on the handles. But this type of break can not make a box where there has already been a prior bend.

This is made by Sieg, the same company that makes the Mini Machine Tools.

There is a Profiform version that comes in two widths called the 200 (8") or 320 (12"). It's manual goes into some detail about setting the cutting tools. When properly set you can cut typing paper. This version has many accessories available that would also work on the Harbor Freight version.

The 12" Bench Top Hand Shear does the job I was trying to do with this product, i.e. cut Printed Circuit Boards. Plus it can cut other things, like paper to make business cards.

This may also be called a pan and box break because it can bend metal that already has prior bends. Also called a press break, which is different than the folding type of break. The Harbor Freight 18" break 39103 is similar to a flat table top with a hinge. To use it you need to trap the metal using the supplied bar with C clamps then pull up on the handles. But this type of break can not make a box where there has already been a prior bend.

This is made by Sieg, the same company that makes the Mini Machine Tools.

There is a Profiform version that comes in two widths called the 200 (8") or 320 (12"). It's manual goes into some detail about setting the cutting tools. When properly set you can cut typing paper. This version has many accessories available that would also work on the Harbor Freight version.

The 12" Bench Top Hand Shear does the job I was trying to do with this product, i.e. cut Printed Circuit Boards. Plus it can cut other things, like paper to make business cards.

Shear

The shear is at the top and

consists of

a horizontal top cutting bar and a sloped lower cutting

bar.

There is a gap in the top of the casting that's less than 2

mm

0.079" deep that limits the thickness of material that you can

cut (1.5

mm spec = 0.059"). 1/16" printed circuit board material

(0.0625)

just fits and is easily cut. It would be better if the

casting

was sanded to knock off the high spots (mainly paint but also

casting

bumps). This was my application.

4 Jun 2007 - The shear will cut the ExpressPCB Mini boards (2.5" x 3.8") where typically the first cut is about 1.25" with no problem. But if you're cutting a board that has 3 or more inches under the blade then it's very difficult. I've found using a scribe to weaken the board on the top and bottom prior attempting to shear it helps. For really large boards I still use the scroll saw that bolted under a table in the garage.

27 Oct 2007 - The Harbor Freight 38413 Throatless Shear may be a better way to cut printed circuit boards? If you have one let me know.

A 3 foot floor mounted sheet metal shear that's foot operated will cut a 12" PCB like it was butter, but they are big and cost more than what I want to spend for this.

I think the problem is the design of the mechanism that drives the blade. There's not enough leverage and with more leverage the drive pins will snap. But I haven't done any calculations to see what the stresses are in the shear and frame. If they are low for say a 5" wide 1/16" double sided PCB then it would be worth looking at a better drive system, like a hydraulic ram.

4 Jun 2007 - The shear will cut the ExpressPCB Mini boards (2.5" x 3.8") where typically the first cut is about 1.25" with no problem. But if you're cutting a board that has 3 or more inches under the blade then it's very difficult. I've found using a scribe to weaken the board on the top and bottom prior attempting to shear it helps. For really large boards I still use the scroll saw that bolted under a table in the garage.

27 Oct 2007 - The Harbor Freight 38413 Throatless Shear may be a better way to cut printed circuit boards? If you have one let me know.

A 3 foot floor mounted sheet metal shear that's foot operated will cut a 12" PCB like it was butter, but they are big and cost more than what I want to spend for this.

I think the problem is the design of the mechanism that drives the blade. There's not enough leverage and with more leverage the drive pins will snap. But I haven't done any calculations to see what the stresses are in the shear and frame. If they are low for say a 5" wide 1/16" double sided PCB then it would be worth looking at a better drive system, like a hydraulic ram.

Missing Accessory - Cutoff Length Guide

The Lower Blade Support Bar (Item 8) has a couple of 8 mm

holes in each

end and there are a couple of pinch bolts that are intended to

hold

something. As of 16 Feb. 2006 I think the missing

accessory is a

right angle cutting guide. When installed the guide

would allow

you to align material on the guide and then make a cut 90

degrees from

the guide. This would allow squaring up material that

started out

with only one straight side. But I have not seen anyone

offering

this useful accessory. As it is now if you cut out a

piece of

metal that's small enough to fit into this mini shear using

tin snips

or a power sheet metal cutter (Harbor Freight 92148

electric sheet metal shear) it will not be square. So

without the

missing guide you need to do layout and marking of the work

piece just to get it square. With the missing guide it

would be a

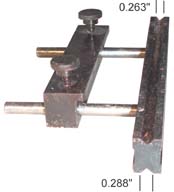

snap to square it up.Guide (Item # 16)

The

Guide

(16)

has a couple of thumb screws that pinch on the two 8

mm rods coming out of the lower "V" groove die. The

purpose of

the guide is to both set the length of metal to be bent and to

keep it

parallel to the bending line. The Guide has a lip that

must be

positioned on the top side and facing the bending dies.

It would

be wrong to feed the metal below the lip and above the rods

because

doing so would not allow the metal to move upwards as it's

bent.

So the tip of the lip must be the intended stop for the

metal.

But the amount of lip protrusion is only 4.83 mm

(0.190"). This

is about the length of the flat on top of the lower die, but

it is not

long enough to be over the bending line. If it was half

(0.311")

of the lower die width (15.71 mm or 0.622") then when

closed the

length of the material to be bent would be zero. If the

guide was

moved 0.25 inches away from the lower die the material that

was bent

would be 0.25" , etc. making setting the positon of the guide

easy.

BUT that's not the case. So was the guide made

improperly,

or is there some reason for the strange lip protrusion

distance?

The

Guide

(16)

has a couple of thumb screws that pinch on the two 8

mm rods coming out of the lower "V" groove die. The

purpose of

the guide is to both set the length of metal to be bent and to

keep it

parallel to the bending line. The Guide has a lip that

must be

positioned on the top side and facing the bending dies.

It would

be wrong to feed the metal below the lip and above the rods

because

doing so would not allow the metal to move upwards as it's

bent.

So the tip of the lip must be the intended stop for the

metal.

But the amount of lip protrusion is only 4.83 mm

(0.190"). This

is about the length of the flat on top of the lower die, but

it is not

long enough to be over the bending line. If it was half

(0.311")

of the lower die width (15.71 mm or 0.622") then when

closed the

length of the material to be bent would be zero. If the

guide was

moved 0.25 inches away from the lower die the material that

was bent

would be 0.25" , etc. making setting the positon of the guide

easy.

BUT that's not the case. So was the guide made

improperly,

or is there some reason for the strange lip protrusion

distance?Also, how to determine which "V" goove in the lower die should be used?

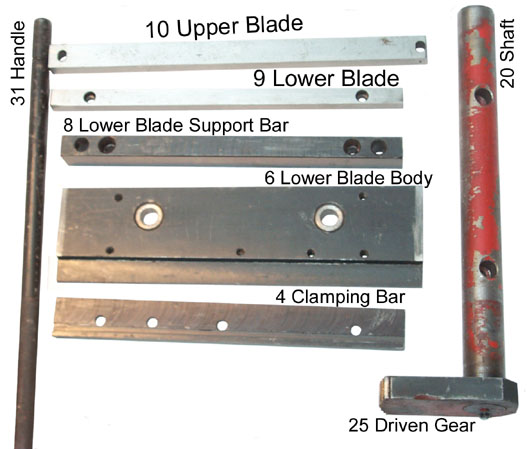

Shear Blades (9 & 10)

The blades are rectangular in

cross

section so that they can be installed 4 different ways, each

of which

presents a new cutting edge.

Break

The break is at the bottom of

the

tool. It is of the type that has a lower die shaped

like a "V"

block and an upper die that has a 90 degree "v" point.

When the

upper die is pressed down on sheet metal it's bent into a 90

degree

angle if the die is pressed home.

Upper Dies

The tool comes with an 8

inch wide top

die installed, but also supplied are four narrow dies of

different

lengths. This

allows setting up the break to bend a number of different

widths.

Lower Die

The lower die is a bar with

a "V"

groove on the top side and another "V" groove on the

bottom side.

The grooves are of different depths to accommodate

different material

thickness. Swaged into this die are a couple of 8 mm

rods that

extend back to a "Guide" that has a couple of thumb screws

for pinching

it to the rods. This allows setting the length and

squares of the

metal prior to bending.

Applications

- Cutting Printed Circuit Boards - I received an email

saying that

the 8MSB they received would not cut a 1/16" PCB out of

the box.

I'm guessing this particular unit got mis-aligned during

shipment

and/or has a number of surfaces that are painted instead

of smooth and

greased. TBD.

- Making Zero Gauss Chambers (mini boxes made from Mu-Metal)

- Prototype sheet metal work

- Learning what can easily be done and what's impossible

Hints

Bending Metal

In the above photo the top 8 inch die has been repositioned to the left and a couple of the small top dies have been installed on the right. The hope was to have just one setup, but for a mini box that's 1 x 1 x 3 3/4" it did not work. After some bends you need to remove the top dies to get the part out of the break.I'm making drawings and printing them at 1:1. Taping the drawing onto the metal and cutting the metal to the drawing.

Do not use scissors or shears to cut the notches. It will cause the metal to get bent (not flat). Do use a nibbler which does not bend the metal then with a vise and file clean up the edges. I tried using the 18 Gauge Electric Metal Shear 92148 but the thin metal was very distorted after cutting.

Klein makes a nibbler very similar to the one I have.

Maybe after a lot of practice my precision will improve, but for now some tolerance needs to be part of the design. Even better is to make one half of the box, measure it then make the other drawing to fit the existing part (selective assembly was the norm before tolerances were developed.)

8" Digital Calipers (Harbor Freight 47260) are very handy for design and layout of parts for this shear break.

Cutting PCBs

Each time you use the 8MSB for cutting anything, cycle the blade up and down to be sure that it moves freely and that the blades do not collide.The stock 8MSB has paint runs on the top surface of the frame casting and these will keep a 1/16" from being positioned in some spots and may keep it out all together. Sand paper will get rid of the high spots. Still working on a good way to do this without taking apart the top cutting blade.

What goes Wrong

Drive Pins

29

April

2006

- Yesterday I received a replacement 8MSB and cycled the

cutting blade up and down with nothing in there and it worked

fine. Then tried to cut a 3 3/4" wide PCB, but it would

not fit,

so used sandpaper to knock off the paint runs. Then cut

the board

up with no problem (this done without bolting it down).

This

means that the first 8MSB was put out of alignment by my wife

using it

as an anvil. The hammering on the top blade clamp did

something

to the blade alignment.

29

April

2006

- Yesterday I received a replacement 8MSB and cycled the

cutting blade up and down with nothing in there and it worked

fine. Then tried to cut a 3 3/4" wide PCB, but it would

not fit,

so used sandpaper to knock off the paint runs. Then cut

the board

up with no problem (this done without bolting it down).

This

means that the first 8MSB was put out of alignment by my wife

using it

as an anvil. The hammering on the top blade clamp did

something

to the blade alignment.When I get the new drive pins for the old one I'll learn how to do the blade alignment. This also means that you should not use washers or other spacers to widen the gap since they may not be stable enough to maintain the blade alignment.

20 April 2006 - Tried to cut a panelized printed circuit board but it would not cut. I don't have the shear break bolted down and in the past was able to easily cut printed circuit boards that were narrower. So tried using more force, but you can't use much when the shear is not bolted down. Then without hearing or feeling anything unusual the lower blade stopped moving. After taking it apart is was clear that both drive pins had sheared. Harbor freight offered "used" parts, i.e. taken off another mini shear break that was not sellable, but I opted to get new pins which will take 6 to 8 weeks.

After more inspection the following problems are apparent:

- Many surfaces where metal parts are rubbing against other metal parts are painted on one or both surfaces. The paint needs to be removed and replaced by grease.

- Where metal parts rub against each other there are burs that need to be filed down.

- The Drive pins (Item # 19) are a poor design. The

tapped

hole extends to the narrow neck area making the neck very

weak. A

0.1365 inch diameter hole through a metal part that's only

0.280 O.D.

leaves only a 0.071 inch thick wall for an area of

0.047 square

inches. If the tapped hole was a little less deep

the area at the

neck would be 0.062 square inches or 130 percent

more. In

addition to the difference in area, the hole also acts as

a stress

riser

further weakening the part. The tip of the drive pin

should be a

sphere, but these look more like a couple of chamfers were

used to

approximate a sphere. There are shiny metal spots on

the edges of

the flat part.

A new mini shear break has arrived and is not being taken apart.

Harbor Freight will take orders for spars parts, but it takes many many months to get them (so for nothing has arrived). Micro Mark stocks cutting blades but will not order any other spare parts.

Shear

On a few occasions I've been able to make a nice cut, but the next time not. You would think it would work on the 10 mil Phosphor Bronze (see below or brass).Maybe there needs to be another adjustment or fix. So examining the parts:

Suggested Improvements

These are pending more work on

the old

unit. Coming about June 2006.

- removing paint that's between metal to metal moving surfaces and replacing it with grease.

- polishing the drive pin ends into shiny spheres and greasing them.

- Confirming that the slide assembly moves smoothly up and down without binding and greasing it.

- Remove the top cutting blade and it's support bar and removing all the paint on the top. This is the bottom of the slot where the printed circuit board needs to fit and if the paint is too thick or has a run a 1/16" PCB will not fit. So this is mainly to be sure the board fits cleanly.

- Clean off the old waxy grease from the drive gear teeth

and

replace with fresh grease.

-

I expect that the new replacement parts will also have the

tapped

hole

too deep.

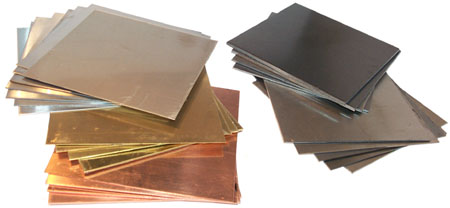

Sample Sheet Metal Packs

On Line Metals - offers a number of "Metal" packages offered under the catagory sample packages but these packages only have rod stock in various metals. But they also have sheet metal sample packs offered under each metal.

These sheet metal sample packs contain 4" x 4" samples in various thicknesses. Many of them are too thick to cut with the 8" MSB but many will work just fine.

Not shown is a sheet of Nickel Silver also from OLM.

On the left are the T-304 #4 and T-304 #2B Stainless Steel, Brass and Copper packs and on the top right the A569 Hot rolled steel and at bottom right the 4130 cold rolled steel.

Phosphorous Bronze

For making motor brushes for the Weeden Toy DC motor and the Small DC motor (similar to the Gilbert Toy Motor) I've got a roll of 12" phosphor bronze that's spring tempered.

A 6" strip can be cut off the roll with heavy scissors then sliced using the 8" MSB. But first the top cutting blade needed to be adjusted. The first try just folded the 0.010" thick metal. It also would not cut a 3x5" paper card.

Loosen the top front clamping hex screws and finger tighten them. Raise the lower cutting blade so it's past the top blade cutting edge. Loosen the adjusting lock nuts and run the hex adjusting screws forward with a small torque and lock the nuts. It should cut 3x5" card stock at any location across the blade. Adjust as necessary to get good paper cutting.

Now it does a good job on 6" wide metal.

To order a 3" x 3" x 0.009" piece of phosphor bronze see the Phosphor Bronze Brush Kit.

Tin Snips

These are the Enco 891-5590 Straight. Cut 12.5" Wiss Tin Snips

I have had other kinds in flavors like left cutting, right cutting or straight cutting that had serrated teeth on the blades. Also the Cutco heavy duty kitchen shears can cut a penny, but they too have serrated cutting blades that leave a rough edge on the cut metal. These shears were chosen to cut the phosphor bronze and brass sheet metal and most if not all these cuts are straight.

25 Sep 2008 - these will easily cut 1/16" PCB material for about half an inch per squeeze. So to separate a 2.5" x 3.8" ExpressPCB Mini board into three boards each 2.5" long (i.e. the cuts are 2.5" long) takes a couple of squeezes from each side. replaced by the 12" shear for PCB cutting.

Brooke's other Metal Working web pages

12"

Bench Top Hand Shear

5C Tool room lathes when working in the Microwave business the shop was full of them

8" Mini Shear Break

Active Storage - shelving and box sizes

Air Tools

Digital-Retro-Turbo-Encabulator

Drill Press used with 5C collets

Electric mains power Generators

Farm Hi Lift Jack

Geodesic Dome Connector Plates

Hints & Tips What Goes Wrong

Lathes for < 1" OD parts (5C collets)

Mini Machine Tools (Lathes and Mills) One of my dreams

Fasteners A page made for my own use with dimensions of common fasteners used for product design and for looking at new ideas for products

Measuring Tools Used mainly for reverse engineering

Pocket Tools

5C Tool room lathes when working in the Microwave business the shop was full of them

8" Mini Shear Break

Active Storage - shelving and box sizes

Air Tools

Digital-Retro-Turbo-Encabulator

Drill Press used with 5C collets

Electric mains power Generators

Farm Hi Lift Jack

Geodesic Dome Connector Plates

Hints & Tips What Goes Wrong

Lathes for < 1" OD parts (5C collets)

Mini Machine Tools (Lathes and Mills) One of my dreams

Fasteners A page made for my own use with dimensions of common fasteners used for product design and for looking at new ideas for products

Measuring Tools Used mainly for reverse engineering

Pocket Tools

Links

Brooke's web pages

Mini Machine Tools - small lathes and milling machinesLathe - 5C collet size lathes for 1" and smaller parts

Length & Weight Measurements - tools

Fasteners

Mini Cut-off Saw

Pocket Tools - multi purpose tools

Electro Optical Gadgets - includes linear and rotation digital readouts

Micro Mark - 7x12 Lathe - also made by SIEG but much enhanced

LittleMachineShop -

[an error occurred while processing this directive] page created 16 Feb 2006.