Mini Cut-Off Saw

© Brooke Clarke 2007

Background

Features Listed on Box

Setup

Blade

Hold Down

Vise

Belt Drive

Operation

Summary

Ideas

Similar Saw

Larger Saws

Brooke's other Metal Working web pages

Three Replacement blades are HF Item42085. They are marked:

#42805, Fits #42307 Mini Cut-off Saw, Max RPM 13,000

The blister pack is marked:

M2 High Speed Steel, 2" dia., 3/8" Arbor.

There are 100 teeth on a 2" diameter circle which works out to a pitch of 0.0314" (0.8 mm).

The rule of thumb is the material should be at least as thick as the blade pitch. This blade would be suitable for cutting thin material. Unlike the blade I mistakenly got for the drill press where the pitch was 0.314", not suitable for small diameter stock.

I've heard the Proxxon KG 50 is very sensitive to the pressure applied to the handle and it has a saw with three times larger pitch. This saw may have the finest pitch blade which helps when cutting thin material.

If you apply too much pressure and the pitch is greater than the material thickness the saw may advance so much that when the next blade comes around the depth of cut is more than it can handle and it stalls. When there's at least one tooth in the material at all times, then you can not advance the blade without feeling the saw slow. Having a few teeth in the material is even better. The old metal working books have some tips like mounting sheet material in a sandwitch between blocks of material of similar density then sawing.

The blade is 0.024" thick ( 0.61 mm) and leaves a kerf of about 0.026" (0.66 mm).

The red plastic post behind the 3/8" brass rod is a safety device that prevents the saw from being lowered until the red plastic button on the top of the handle is pressed.

A 3" diameter blade would clear the motor housing, but not the gray plastic blade cover.

Harbor Freight sells a 3" OD abrasive cutoff wheel (44812) that has the same arbor size and fits this saw, but the OD is larger and the gray plastic guard does not fit. I used one to cut the end off of the top hardened steel cutting bar from the 8" Mini Shear Break. The normal saw or a hack saw would not touch the metal. I kept all parts of my body out of the saw plane incase it exploded and was wearing safety glasses. It took a couple of hours to make the cut.\

23 March 2008 - The saw blade is not suited fop cutting iron, but the abrasive wheel will cut a 1/2 x 1" iron bar, BUT it takes some number of hours. In exchange you get a cut that's almost a mirror finish. A portable or fixed band saw would be much better for cutting iron.

As

can be seen in the photos the movable vise jaw has a "V" groove

that

be used when holding round stock. But they put the "V" on

the

wrong face. The way it is the movable jaw can pivot about

the

clamping screw centerline a few degrees so the cut will be a few

degrees from 90. If the rear jaw had the "V" groove then

the cut

angle would be near perfect.

As

can be seen in the photos the movable vise jaw has a "V" groove

that

be used when holding round stock. But they put the "V" on

the

wrong face. The way it is the movable jaw can pivot about

the

clamping screw centerline a few degrees so the cut will be a few

degrees from 90. If the rear jaw had the "V" groove then

the cut

angle would be near perfect.

Packing material could be placed between the movable jaw and the work piece so the "V" groove would not try to control the position of the work piece. Note there is a raised floor that's 0.588" wide and about 0.080" high at the bottom center of the vise. The ledge on the left (rear in photo at left) is 0.010" lower than the raised vise floor. Note this raised floor is to allow the blade to cut all the way through the work piece without making a slot in the base to clear the blade.

The pivot pin can be seen in this photo of the vise when it's removed from the saw. Notice just above and to the right of the pivot pin the vise has a miter cut to clear the blade when making a miter cut. The square nut on the vise clamp bolt rides in a circular groove under the saw base.

If the vice is removed then the blade will cut into the base. There's a bump on the bottom of the motor assembly coaxial with the saw arbor that hits the top of the vice and that stops the motor assembly from going any lower. At that point the blade is below the level of the raised part of the vice bed between the jaws.

The toothed belt is being driven 1:1 from the motor. The

belt has

markings:

The toothed belt is being driven 1:1 from the motor. The

belt has

markings:

DO NOT CRIMP 88 MXL B 110 MXL 025 05 05 043 JIEBAO

It's a little over 6.5 mm wide.

I ordered a spare belt and it arrived with the saw.

[an error occurred while processing this directive]page created 8 Dec 2007

Features Listed on Box

Setup

Blade

Hold Down

Vise

Belt Drive

Operation

Summary

Ideas

Similar Saw

Larger Saws

Brooke's other Metal Working web pages

Background

Recently I've started working

with 5C

collets in my drill press and

can do

some of the operations that I

would do in a lathe if I had a lathe. But there is a

need to cut

the raw material and end up with an end that's square and

reasonably

smooth. Ordered from Harbor Freight: Mini Cut-off

Saw 42307

on 27 Nov 2007 and it came today 8 Dec 2007.

This may be a design based on the Proxxon KG 50 Cutoff Saw. The Proxxon has more features and I'm sure is a much higher quality product, but at a much much higher price. They both use blades that fit a 3/8" arbor 2" dia blades. The KG 50 is listed on their European web site. but does not show up in the 2.5 MB US catalog.

This may be a design based on the Proxxon KG 50 Cutoff Saw. The Proxxon has more features and I'm sure is a much higher quality product, but at a much much higher price. They both use blades that fit a 3/8" arbor 2" dia blades. The KG 50 is listed on their European web site. but does not show up in the 2.5 MB US catalog.

Features Listed on Box

- Make perfect cuts in 1/10 the time it takes to cut by hand.

- Cuts are smooth and accurate - no need to sand cut ends.

- 110 VAC, 60 Hz, 0.9 Amps, 7800 Max PRM

- Arbor: 3/8", Cutting depth: 3/4"

- Miter gauge: 0 - 45º

Setup

Be sure to remove the saw blade that's taped to the box before tossing the box (best to keep the box for storage). The blade needs to be installed prior to use. The gray blade cover can be removed by just slipping it up. The arbor has a step that centers the blade. It attaches with a Phillips #2 screw. The front edge of the blade moves down (Counter Clock Wise in the photo at the left) and there's an arrow printed on the blade so that it's gets installed in the proper way.Three Replacement blades are HF Item42085. They are marked:

#42805, Fits #42307 Mini Cut-off Saw, Max RPM 13,000

The blister pack is marked:

M2 High Speed Steel, 2" dia., 3/8" Arbor.

There are 100 teeth on a 2" diameter circle which works out to a pitch of 0.0314" (0.8 mm).

The rule of thumb is the material should be at least as thick as the blade pitch. This blade would be suitable for cutting thin material. Unlike the blade I mistakenly got for the drill press where the pitch was 0.314", not suitable for small diameter stock.

I've heard the Proxxon KG 50 is very sensitive to the pressure applied to the handle and it has a saw with three times larger pitch. This saw may have the finest pitch blade which helps when cutting thin material.

If you apply too much pressure and the pitch is greater than the material thickness the saw may advance so much that when the next blade comes around the depth of cut is more than it can handle and it stalls. When there's at least one tooth in the material at all times, then you can not advance the blade without feeling the saw slow. Having a few teeth in the material is even better. The old metal working books have some tips like mounting sheet material in a sandwitch between blocks of material of similar density then sawing.

The blade is 0.024" thick ( 0.61 mm) and leaves a kerf of about 0.026" (0.66 mm).

The red plastic post behind the 3/8" brass rod is a safety device that prevents the saw from being lowered until the red plastic button on the top of the handle is pressed.

A 3" diameter blade would clear the motor housing, but not the gray plastic blade cover.

Harbor Freight sells a 3" OD abrasive cutoff wheel (44812) that has the same arbor size and fits this saw, but the OD is larger and the gray plastic guard does not fit. I used one to cut the end off of the top hardened steel cutting bar from the 8" Mini Shear Break. The normal saw or a hack saw would not touch the metal. I kept all parts of my body out of the saw plane incase it exploded and was wearing safety glasses. It took a couple of hours to make the cut.\

23 March 2008 - The saw blade is not suited fop cutting iron, but the abrasive wheel will cut a 1/2 x 1" iron bar, BUT it takes some number of hours. In exchange you get a cut that's almost a mirror finish. A portable or fixed band saw would be much better for cutting iron.

Hold Down

The saw can be anchored to a table using two #8 Flat head screws. 3.3" (84 mm) c-c. Either wood screws if you have a wood work surface or machine screws if working with through holes. The base is a die casting, not plastic. The supplied "C" clamp fits the slot at the front center of the base and works well. This has the big advantage that it's very quick and easy to install the saw when you want to use it, and store it otherwise, thus not taking up limited bench space.|

CAUTION

Once the blade is installed if you pick-up the saw it's easy to grab the blade. |

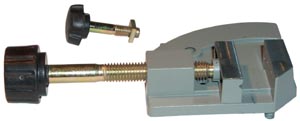

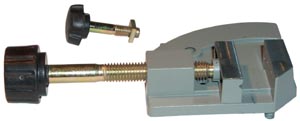

Vise

The vise can be rotated so that

a miter

cut can be made. The vise is die case not plastic.

As

can be seen in the photos the movable vise jaw has a "V" groove

that

be used when holding round stock. But they put the "V" on

the

wrong face. The way it is the movable jaw can pivot about

the

clamping screw centerline a few degrees so the cut will be a few

degrees from 90. If the rear jaw had the "V" groove then

the cut

angle would be near perfect.

As

can be seen in the photos the movable vise jaw has a "V" groove

that

be used when holding round stock. But they put the "V" on

the

wrong face. The way it is the movable jaw can pivot about

the

clamping screw centerline a few degrees so the cut will be a few

degrees from 90. If the rear jaw had the "V" groove then

the cut

angle would be near perfect. Packing material could be placed between the movable jaw and the work piece so the "V" groove would not try to control the position of the work piece. Note there is a raised floor that's 0.588" wide and about 0.080" high at the bottom center of the vise. The ledge on the left (rear in photo at left) is 0.010" lower than the raised vise floor. Note this raised floor is to allow the blade to cut all the way through the work piece without making a slot in the base to clear the blade.

The pivot pin can be seen in this photo of the vise when it's removed from the saw. Notice just above and to the right of the pivot pin the vise has a miter cut to clear the blade when making a miter cut. The square nut on the vise clamp bolt rides in a circular groove under the saw base.

If the vice is removed then the blade will cut into the base. There's a bump on the bottom of the motor assembly coaxial with the saw arbor that hits the top of the vice and that stops the motor assembly from going any lower. At that point the blade is below the level of the raised part of the vice bed between the jaws.

Belt Drive

The toothed belt is being driven 1:1 from the motor. The

belt has

markings:

The toothed belt is being driven 1:1 from the motor. The

belt has

markings:DO NOT CRIMP 88 MXL B 110 MXL 025 05 05 043 JIEBAO

It's a little over 6.5 mm wide.

I ordered a spare belt and it arrived with the saw.

Operation

It took just a few minutes to

take the

saw to my garage work bench and clamp it down. It took a

few

seconds to cut off a slice from the 3/8" brass rod.

I'm thinking I'll store the saw in it's box rather than take up bench space by installing since it's so easy to set up.

Although

you

can see some saw marks the end is almost mirror like.

The

back side of the slice has the saw marks from On Line Metals which

was

probably cut using a power hack saw. The Mini Cut-off

saw is much

much smoother.

Although

you

can see some saw marks the end is almost mirror like.

The

back side of the slice has the saw marks from On Line Metals which

was

probably cut using a power hack saw. The Mini Cut-off

saw is much

much smoother.

Notice it's easy to cut off a thin slice of material.

Using a couple of 123 Blocks it's clear that the cut is not square, but that not unexpected (see Vise above).

By pressing this rod down to the bottom of the vise it can be clamped without using the "V" groove.

When the vise is removed it could be replaced by a thin sheet of wood that would be located in the vise pivot hole in the base and get clamped using the vise bolt and square nut. The first time the saw was used it would cut a slot in the wood. If a groove was cut in the wood in a left to right direction, square to the blade, and a small fence fitted it may be possible to cut printed circuit boards. The blade center to the back of the throat is 3". A little shorter to the red plastic safety stop.

These are telescoping brass tubes 0.3135 x 0.285 and 0.344 x 0.316 They both have 0.014" thick walls. Since the blade pitch is 0.031459 I wanted to see how well it would cut these tubes, and as you can see at the end of the cut there's a tag left on the part that's cut off. The part in the vise has a clean cut. Notice that the tubes are still round and these two telescope as they should. Other methods of cutting thin wall tube can distort the tube.

I'm thinking I'll store the saw in it's box rather than take up bench space by installing since it's so easy to set up.

Although

you

can see some saw marks the end is almost mirror like.

The

back side of the slice has the saw marks from On Line Metals which

was

probably cut using a power hack saw. The Mini Cut-off

saw is much

much smoother.

Although

you

can see some saw marks the end is almost mirror like.

The

back side of the slice has the saw marks from On Line Metals which

was

probably cut using a power hack saw. The Mini Cut-off

saw is much

much smoother.Notice it's easy to cut off a thin slice of material.

Using a couple of 123 Blocks it's clear that the cut is not square, but that not unexpected (see Vise above).

By pressing this rod down to the bottom of the vise it can be clamped without using the "V" groove.

When the vise is removed it could be replaced by a thin sheet of wood that would be located in the vise pivot hole in the base and get clamped using the vise bolt and square nut. The first time the saw was used it would cut a slot in the wood. If a groove was cut in the wood in a left to right direction, square to the blade, and a small fence fitted it may be possible to cut printed circuit boards. The blade center to the back of the throat is 3". A little shorter to the red plastic safety stop.

These are telescoping brass tubes 0.3135 x 0.285 and 0.344 x 0.316 They both have 0.014" thick walls. Since the blade pitch is 0.031459 I wanted to see how well it would cut these tubes, and as you can see at the end of the cut there's a tag left on the part that's cut off. The part in the vise has a clean cut. Notice that the tubes are still round and these two telescope as they should. Other methods of cutting thin wall tube can distort the tube.

Summary

This seems to be a bargain and

does a

reasonable job of cutting material. Both lower in cost

and better

quality cuts than larger options.

Need to figure out a way to get square cuts and to add a stop so multiple parts can be cut to the same length.

Need to figure out a way to get square cuts and to add a stop so multiple parts can be cut to the same length.

Ideas

Can this saw cut Printed Circuit

Boards, as is maybe by removing the vise and inserting

something, or by

removing the base and mounting the saw on a slide similar to a

radial

arm saw, only at a fixed height and at 90 degrees to a

fence? Will the stock blade be ruined by cutting

PCB

material?

Similar Saw

The Proxxon Chop

& Miter

Saw KGS 80

has similar functionality. It comes with a 24 tooth

3.125" dia

blade i.e. 0.2" pitch, much coarser than the HF 100 tooth

blade.

They fit a 10 mm arbor which is 0.394" that's 18 mills larger than 3/8" and so would be very out of balance if installed on this saw, unless a spacer ring was used.

They fit a 10 mm arbor which is 0.394" that's 18 mills larger than 3/8" and so would be very out of balance if installed on this saw, unless a spacer ring was used.

Larger Saws

For those who are cutting

slightly

larger diameter or harder to cut materials the small band saws

are

popular.

Harbor freight has the Portable Variable Speed Bandsaw 47840 for $70 (sale price). No bench stand included.

Grizzley has the G8692 Portable Bandsaw w/ Stand for $140 (regular price). Two bolts hold the saw to the stand so it can be used either way.

Yahoo Groups

4x6bandsaw - Grizzly/Jet/HF/Enco 4x6 metal cutting bandsaw i.e. the largest rectangle that can be cut is 4" x 6" and a 4x6 page at mini-lathe.com

The Harbor Freight 4x6 on sale 93762-6VGA is $160.

Harbor freight has the Portable Variable Speed Bandsaw 47840 for $70 (sale price). No bench stand included.

Grizzley has the G8692 Portable Bandsaw w/ Stand for $140 (regular price). Two bolts hold the saw to the stand so it can be used either way.

Yahoo Groups

4x6bandsaw - Grizzly/Jet/HF/Enco 4x6 metal cutting bandsaw i.e. the largest rectangle that can be cut is 4" x 6" and a 4x6 page at mini-lathe.com

The Harbor Freight 4x6 on sale 93762-6VGA is $160.

Brooke's other Metal Working web pages

12"

Bench Top Hand Shear

5C Tool room lathes when working in the Microwave business the shop was full of them

8" Mini Shear Break

Active Storage - shelving and box sizes

Air Tools

Digital-Retro-Turbo-Encabulator

Drill Press used with 5C collets

Electric mains power Generators

Farm Hi Lift Jack

Geodesic Dome Connector Plates

Hints & Tips What Goes Wrong

Lathes for < 1" OD parts (5C collets)

Mini Machine Tools (Lathes and Mills) One of my dreams

Fasteners A page made for my own use with dimensions of common fasteners used for product design and for looking at new ideas for products

Measuring Tools Used mainly for reverse engineering

Pocket Tools

Back to Brooke's PRC68, Alphabetical List of all Brooke's Web

Pages,

Products for Sale, Military

Information, Personal Home page5C Tool room lathes when working in the Microwave business the shop was full of them

8" Mini Shear Break

Active Storage - shelving and box sizes

Air Tools

Digital-Retro-Turbo-Encabulator

Drill Press used with 5C collets

Electric mains power Generators

Farm Hi Lift Jack

Geodesic Dome Connector Plates

Hints & Tips What Goes Wrong

Lathes for < 1" OD parts (5C collets)

Mini Machine Tools (Lathes and Mills) One of my dreams

Fasteners A page made for my own use with dimensions of common fasteners used for product design and for looking at new ideas for products

Measuring Tools Used mainly for reverse engineering

Pocket Tools

[an error occurred while processing this directive]page created 8 Dec 2007