The eyelet is very similar to a

rivet except the eyelet has a hole all the way through.

Eyelets are typically made of brass. Eyelets are much easier

to set than rivets. My first exposure to them was making

double sided printed circuit boards at a time prior to vias so

eyelets were installed to make an electrical connection between

the top and bottom layers. They were installed by a

pneumatic powered machine that had auto feed and a foot pedal to

activate the setting operation. The machine came from a shoe

manufacturing operation.

A Grommet is similar but is used with a washer, typically in

fabric. For example the corners of a tarp may have grommets

to allow using ropes to hold it.

This is tooling

that allows using the press function of a

Drill Press (not the drill motor) to

set eyelets.

The top tool has a central cone to flare out the eyelet's open end

and then a radiused part to form the reverse bend.

The bottom tool holder has 3/8-16 threads that match the

T-slot fittings for this bench top

drill press and so an Enco flanged nut (

407-5024)

with it's points ground very slightly makes a good centered fit

into the top drill press table center hole. All that's

required to line up the top and bottom tools is to rotate the

table left or right a little and then clamp it.

The bottom tool holder appears to have been made from a bolt that

has two concentric holes drilled on the long axis. The upper

hole is about 1/4" diameter and holds the bottom anvil. The

retractable pin sticking up in the center fits inside the shank of

the eyelet, but it too big to clear the small lip at the end of

the eyelet thus it will lift up an eyelet that's shorter than it's

height above the anvil. The lower hole clears the coil

spring. That a very handy thing helping to insert the eyelet

into the work piece. Below the retractable pin is a spring

pushing it up.

If you try to form an eyelet without a pin inside the eyelet body,

the body will crumple instead of holding it's shape. Another

way to get the needed internal support is to make the top tool

with a fixed pin that will go into the hole in the anvil.

Eyelets are available in

many diameters and

lengths. The nominal diameter of the hole is how the

diameter is specified and the ones I'm using are 3/32, 1/8 and

5/32". The 3/32" tooling is shown in the photo.

In order for the top tool to fit inside the snaps used for 9 Volt

batteries the diameter has been reduced from what a stock top tool

looks like. This was done with the tool in the drill press

with the motor running using a hand held grinding stone.

The top tool is installed in the chuck with it's top end seated on

the inside of the chuck so when downward pressure is applied the

tool will not slip in the chuck jaws. It takes some force to

seat an eyelet, but not by any means excessive.

Offset Eyelet Drill Press setup

In the above photo the bottom tool is located in the center hole

of the movable table. In the photo at the left the bottom

tool (including the pin and spring) are located in a custom offset

holder made from 1" x 1/2" iron bar. in the end of the bar

there's a 6-32 tapped hole for a pinch screw. That stock

round head screw does not work because it does not let the center

of the bottom tool get to the center position of a AA battery in

the battery holder.

The movable drill press table can be tilted left to right and when

pressure is applied to seat an eyelet the table tips to the right

no matter how tight the locking nut is tightened. The fix

for that is to install a one foot long 3/8-16 all thread rod, four

nuts and four washers to lock the distance between the drill press

base and the table.

Siska Manual Tooling

The Siska tooling uses a system that does not need a receding

center pin. Their bottom tool does the eyelet forming unlike

the Keystone tooling where the top die does the forming. The

Siska top tool has a center clearance hole and the bottom die has

a fixed pin.

The top and bottom

dies

fit a 3/8" diameter hole in either this manual tool holder set or

into the arbor press or more automated machines.

The shank diameter is very important since it needs to clear

whatever is near the eyelet.

A locating point is shown on a bottom tool that makes a scored

setting. I prefer the roll setting where the lower die would

have a half doughnut around the center pin.

The

next step up from hand tooling is an

arbor press.

They come in 1/2, 1 and 2 ton capacities.

The key advantage I see is that the alignment between the top and

bottom tools is much better.

When using a lower die with a cutting point (just a square top

with sharp corners), it's important that the top and bottom dies

are well aligned.

The two adjusting screws on the front would allow minimizing front

to back slop in the ram. Don't know about side to side slop.

Stimpson 405 Press

I debated getting an arbor press, the Stimpson 405 press or

tooling for using a hammer. The fancier auto feed presses

are what I used long ago to install shoe eyelets into printed

circuit boards to make vias (after soldering each on both

sides), but those presses are too expensive for me. So got

the 405 press with compound linkage and some customized tooling

as well as some of the stock eyelet tooling.

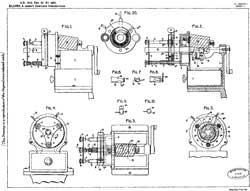

The arbor press is a simple rack and pinion machine where the

mechanical advantage is the operating arm length (minus a

little) divided by the pinion gear radius. This works out

to around 10 and the ratio is the same for all positions of the

arm.

The Stimpson 405 has a three bar linkage and it's mechanical

advantage changes with arm position. It approaches

infinity at bottom dead center. I estimate it at 100 but

it's very dependent on how close to going over center the

tooling allows. Needless to say this makes a huge

difference in ease of use and it's something I didn't know until

I had the press. It would be better to have an adjustable

lower tool so that you could optimize the leverage to match the

thickness of the work.

|

|

|

Stimpson 405 Press

|

GS-5 Stock tooling

|

Compound linkage

|

This is the current version (22 Apr 2008) 405 made from an

aluminum casting. It's impressive to look at with a mirror

like black finish, i.e. anything in the photos that looks like a

blemish is a reflection. The action is smooth and feels

precise, but the proof is in the pudding.

The top and bottom tools use different mating diameters. The

bottom tool is 13/16" and the top too is 3/8". Keystone and

Siska use 3/8" for both tools thus allowing you to install them

either way. Stimpson seems to want you to only install them

one way. The bottom tool requires a 3/16" hex wrench

and the top tool a 1/8" hex wrench. Both tools have flats

for the setscrews and a close fit to the tool.

If you are left handed then the press should be mounted as shown

in the photo at left above. That way you work the press with

your off hand while your precision hand is used to work with the

eyelets. If mounted with the handle facing back you would

need long arms to work it.

In addition to the eyelet tools the 405 also can be used with

Grommet tools and also round sheet metal punches in the size range

of 3/32 to 3/4" diameters.

Custom Tooling

This is a custom tool made to install 9 Volt

battery snaps. The post in the center of the snap is spring

loaded and gets pressed down by the top tool which is shown to the

left upside down. The spring loaded post holds an eyelet,

the PCB and keeps the snap in place until the top tool sets the

eyelet. This is upside down from the stock tooling shown

above but is the correct way to manually do eyelets.

GS Numbers

The GS (Graduated Size) system is based on 1/32" So a GS-5

tool is for use on eyelets that go into a 5/32" (0.156") hole.

GS eyelets are numbered

GS

[hole dia in 32

nds of a inch]

-[Length under flange in 32

nds of a

inch]

The smallest GS series that's mentioned in the Stimson catalog is

GS 2-2 (1/16 dia hole x 1/16 long under flange) and the largest GS

7-14 ( 7/16 dia hole x 7/8" long under flange).

I suspect there's some logical way the flange diameter is

determined but have not tried to analyze it yet.

The Keystone two digit eyelet numbers are the GS numbers.

Tooling

It turns out the stock tooling would work for installing an eyelet

into something thin and flat, but not into real world

applications. Custom tooling is needed.

Caution

A very close tolerance fit is used between the tools and the

press. If an operator that's not mechanically inclined

changes the tools and does not seat the set screw on the tool's

flat, then the precision surface of the tool gets distorted thus

locking the tool into the press. There are a couple of

notches in the tools that allow a wedge to be driven between

the press and tool to get it out. Then the tool needs to be

cleaned up.

Problem

There is a finger shaped metal strap that presses against the

hand lever so that when the lever is up it will stay

there. The problem is the metal of the strap (steel) is

very similar to the metal of the hand lever (cast iron) and so

there is galling. Along with the galling, and the main

reason for the "fix" is the very loud noise that's much worse

than fingernails on a blackboard.

The fix from idea to working took about 10 minutes. Just cut

a strip of

Phosphor Bronze sheet

metal a little wider than the finger, drill a hole for the

mounting screw and put it between the two.

Later an upside down "U" was added to the Phosphor Bronze to keep

it from getting pulled down.

You can buy the Phosphor Bronze from me at:

http://www.prc68.com/P/Prod.html#PBBK

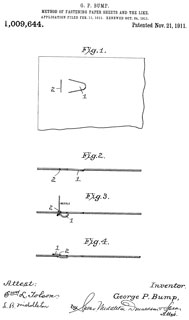

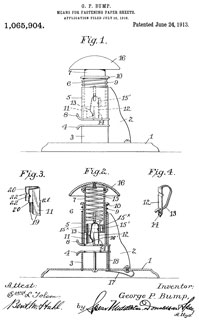

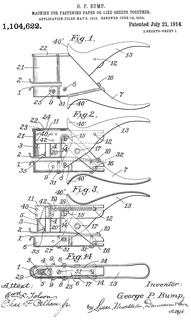

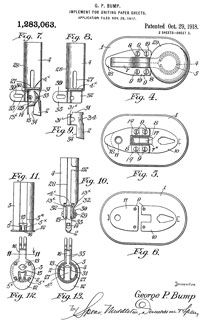

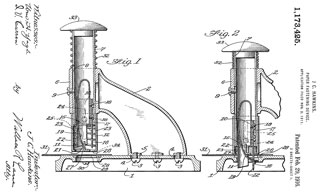

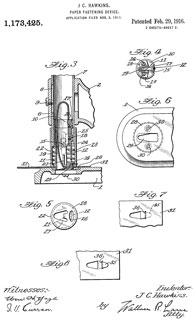

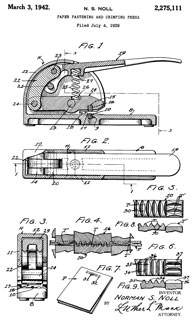

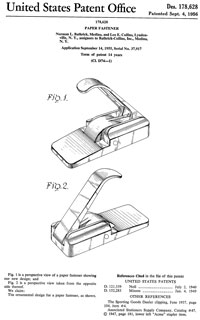

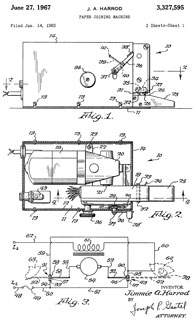

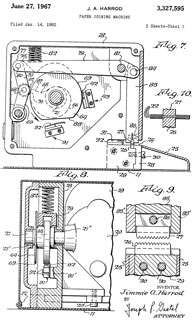

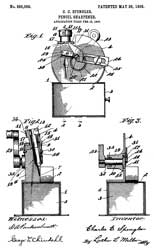

Eyelet Patents

372826 Eyelet-setting

machine, Edwin

B. Stimpson, Nov 8, 1887, 227/60;

221/167; 221/241 - auto eyelet feed, bench top machine

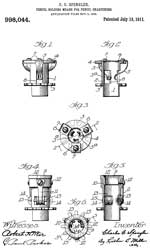

391208

Machine for Setting Eyelets, Edwin

B. Stimpson, Oct 16, 1888, - auto

eyelet feed, bench top machine

736163

Eyeleting-machine, Edwin

B. Stimpson, 1903-08-1, 221/182; 221/188 - foot operated from standing

position, free standing machine

863330

Headless rivet, Edwin

B. Stimpson,1907-08-13, 411/457; 256/54 -

This is a custom tool made to install 9 Volt

battery snaps. The post in the center of the snap is spring

loaded and gets pressed down by the top tool which is shown to the

left upside down. The spring loaded post holds an eyelet,

the PCB and keeps the snap in place until the top tool sets the

eyelet. This is upside down from the stock tooling shown

above but is the correct way to manually do eyelets.

This is a custom tool made to install 9 Volt

battery snaps. The post in the center of the snap is spring

loaded and gets pressed down by the top tool which is shown to the

left upside down. The spring loaded post holds an eyelet,

the PCB and keeps the snap in place until the top tool sets the

eyelet. This is upside down from the stock tooling shown

above but is the correct way to manually do eyelets.