Hints & Tips

What Goes Wrong

© Brooke Clarke, 2001 -

2022

Troubleshooting

Credit Card Fraud

What Goes Wrong

HP 204B Oscillator

R-1004/GRC-109 Receiver

Quantic Q-5200/SM GPS Timing

Receiver

URC-68 Air Crew Survival Radio

OE-254 Antenna

PRC-77 Radio

HP 241A Audio Oscillator

TA-838 Mil Analog Phone

PP-8444A/U Battery Charger

SG-1144/U Signal Generator

SB-22 Switchboard

FTS4060 Cesium Frequency

Standard

Hard Drive Failure

TS-1836C In Circuit Tansistor

Tester

Dead CRT Computer Monitor

Philips 60PP9202 Projection

TV Sudden Red Convergence Problem

Capacitor Failure

PRC-104A Panel + Bent Connector

Electric Wall Single

Oven Cold

GE Electric Wall Oven Error

--F1--

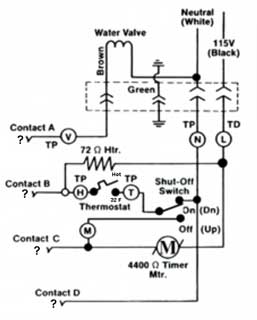

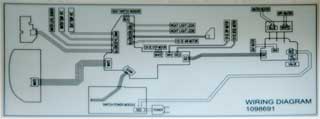

GE Dual Wave III Microwave

Oven JE1468K

Heathkit GC-1000

WWV/WWVB clock

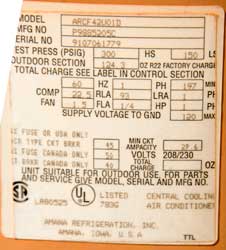

Air Conditioning Compressor

Air Conditioning Fan

Weather

Harbor Freight 93068 PIR

Sensor

Droll Yankees Bird

Feeder

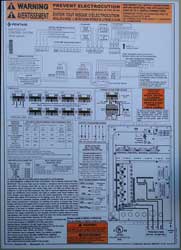

Static & Electrocution

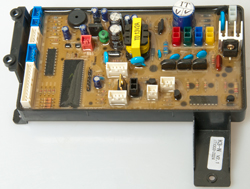

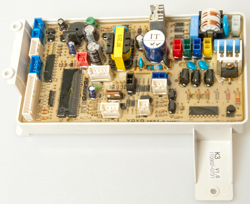

Printed Circuit Boards

Replacing soldered in ICs

Using Solder Wick

Surface Mount Technology -

separate web page

Not Soldering Connections

Magellan GPS

Commander

Reverse Engineering

Loctite

Rubber Parts

Bonding

Plastic

Parts

Car Radio Knob Broken

Cleaning

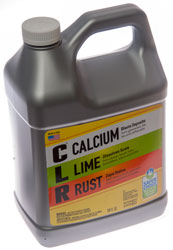

Rust

Lawn Mower

Storage

Design Defects

HP

Doppler Radar Module

LCD

Backlight in PRC-126

Rolls

Royce V8 Engine

Fluke

Test Leads

Lap Top Li-Ion Battery

Precision Time & Frequency

Kitchen Compactor Jam

Refrigerator Door Shelf Failure

Refrigerator Light Lens

Failure

Laptop Headset Connectors go Bad

Comfort Zone Stand Up Portable Room Heater

Squeals and Stops

Battery Replacement

Water Misting

Hoover Upright Vacuum

Door Does Not Latch

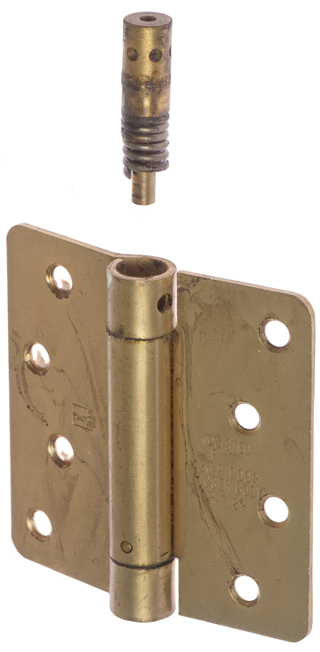

Self Closing Hinge Spring Broken

Aeron Office Chair

Second Office

Chair

Plumbing Stuff

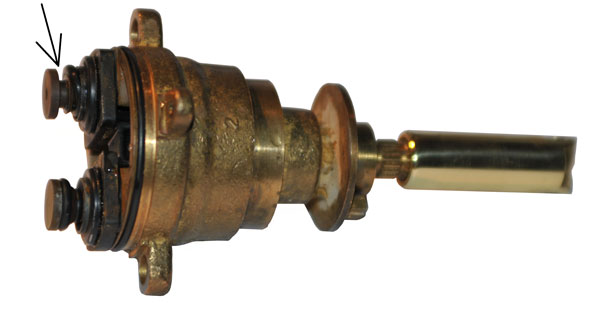

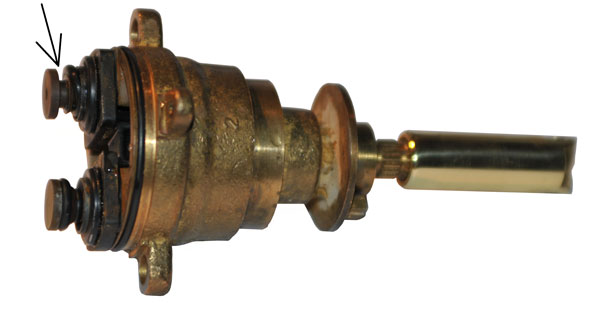

Kohler GP77759 Shower Mixing

Valve

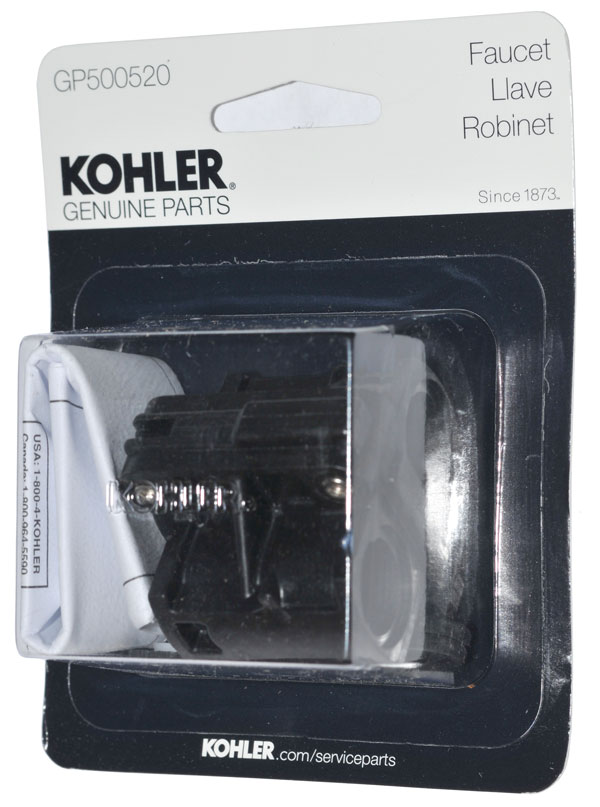

Kohler Sink Valve Backwards

Kohler Shower Temperature Hard

To Control

Kohler 4737-0

Bidet Seat

Leak in Sunpentown

SB-2025L Fitting

Leak in Flap

Valve

Kohler Cimarron

Class 5 Toilet does not "Gulp"

Flap Valves now

obsolete April 2015

Outside Irrigation valves

Danger combining PVC and Galvanized pipe (See: Mains

Pressure Water)

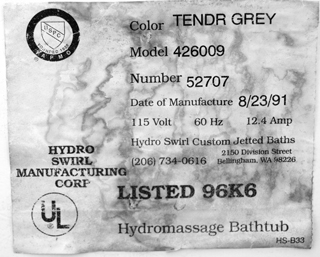

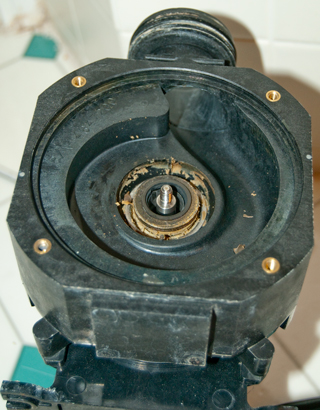

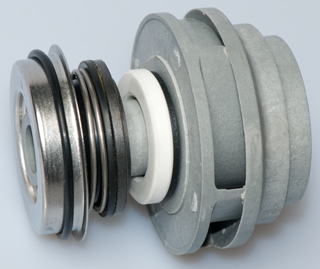

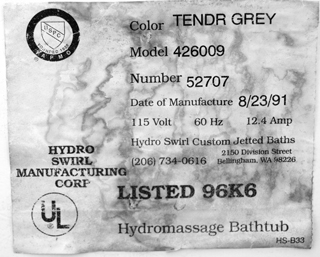

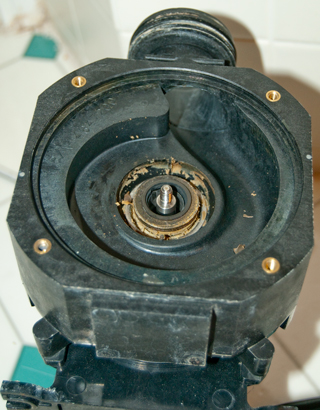

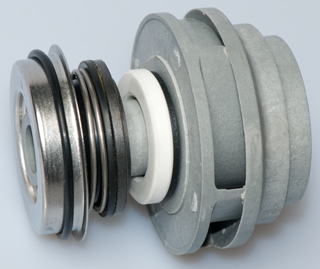

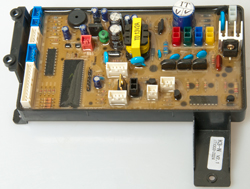

Hydro Swirl 96K6 Pump

Refrigerator Water Filter

SB-2025 Washing Toilet Seat

In Ground Swimming

Pool Skimmer Float Valve Assembly

Propane Tank Leak

Propane Tank Empty

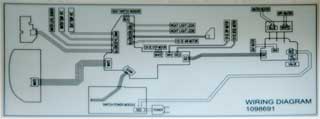

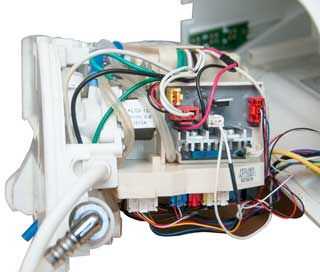

Forced Air Furnace & Air

Conditioner

Icicles

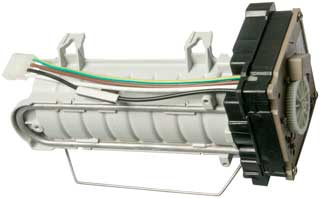

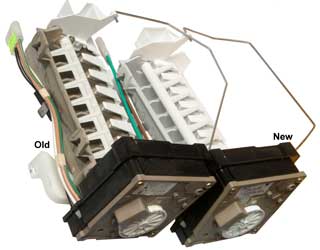

in Freezer

Pentair

iChlor

Water Damage

Kitchen Dish Washer

Kitchen Sink

8

July 2016, 23 Aug Cabinet Repair,

23 Oct 2016

GE Dishwasher Water- new Leak

-This new DW now gone

7 Dec 2016 New Bosch

Dishwasher

Master Bath

Hot Water Heater

Clothes

Washer

Maytag Front Load Washer

Bathrooms

Water Alarms

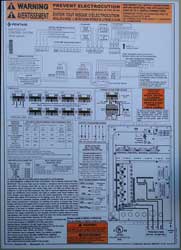

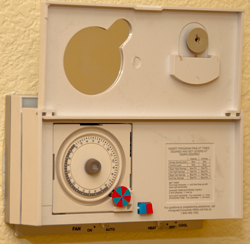

Electrical Wiring

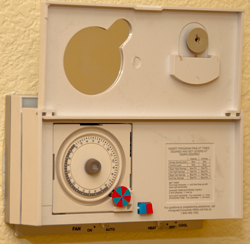

Thermostat

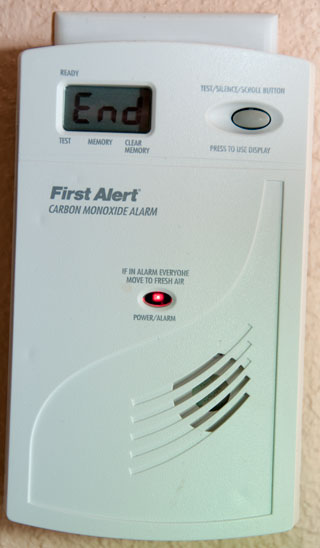

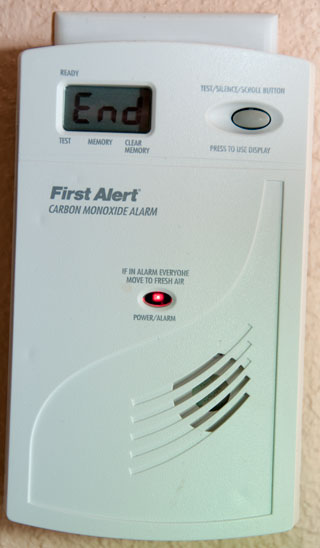

Carbon Monoxide Detector

Forced Air Furnace Wall Outlet

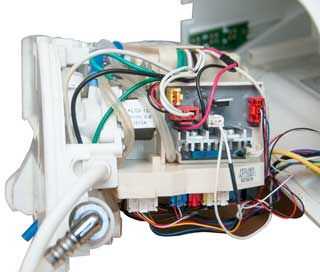

Furnace Controller

Circuit Breakers

Power Line Cords

Old

Line Cords

Dead Refrigerator

Dead Outlet

Room Air

Filter

Gardening

Weed Eater vs. Large

Glass Window

Roll Up Garage Door

Roll Up Garage Door Spring

Roll Up Garage Door Rollers

Roll Up Garage Door Cable

Links

Electronic

Construction Techniques - separate web page

Packaging for Shipment - separate web page

Troubleshooting

When there is a problem it's important to proceed in

this order:

- Cockpit Error - There really is no problem with the

hardware. You are expecting something unrealistic, the

hardware can not do what you expect, you have improperly

configured the hardware, etc.

- Bad Connection - Cycle all controls a number of

times. Apply contact cleaner and cycle controls.

Disconnect and reconnect all connectors and mechanical joints

to burnish their contacts. Power down, wait at least a

minute, power up. This solves 90% of the problems at

this stage.

- Look for common failure modes. So far shorted

capacitors, especially Tantalum types have been the most

common failures I have seen. Also look for semiconductor

devices that test as a short between most if not all

terminals. This can be done using just a DMM in the Ohms

and Diode modes of operation.

- In very rare cases do you need to use more advanced

techniques.

Credit Card Fraud

An email this morning from Capital

One March 17, 2011 time stamped 8:43:

RE: Account ending in 0976

BROOKE,

One of the following changes was made to your Capital One®

VISA SIGNATURE account:

|

1.

|

The mailing address was updated, or |

|

2.

|

You've added an authorized user to

your account |

If you didn't make this change, please call us at

1-800-955-7070—we're available 24/7.

Thanks for using Online Banking.

|

All of my on line addresses (there are three different ones) were

correct.

Calling Capital One I found out that someone had added a "SECRET"

address in LA to my account, so I asked that it be removed.

A couple of hours later received a phone call from an Apple

Computer store asking about my purchase of an Apple laptop

computer for a little over $2000. Needless to say I had not

made that purchase.

Guess where they were going to ship it, yup, the address in LA,

i.e. the SECRET address that Capital One had added.

What Goes Wrong

When Electronic Equipment is unused for years oxidation

forms at the contacts. This adds resistance to the joint and

can cause the equipment to be DOA. When I assembled the 2102

static RAM chips for my SWTP 6800 computer

kit there was an instruction to NOT use sockets because the

reliability of the socket was lower than the chip or solder

joint. By using sockets you would be creating a

problem. The more reliable sockets are Gold plated to avoid

oxidation.

Below are some real examples.

When received from eBay the oscillator did not function. A

check of the power supply showed that it was working fine.

After spraying the OFF-Range switch with Tuner Control Cleaner

& Lubricant (Radio Shack

- 64-4315)

the unit started working.

The problem was oxidation on the switch contacts.

The receiver was DOA upon receipt from eBay. A check of the

power supply showed the correct voltages.

The resistance of each tube filament was checked when it was out

and the tube was installed and removed from it's socket a few

times.

All the filaments were about the same resistance. The most

common failure mode of tubes is that the filaments burn out and

then will test as open circuits. After assembly the receiver

worked well. The problem was oxidation between the tube pins

and the socket. I applied Lube Gel (an insulating Silicon

grease) to the tube pins. The idea is that at some points

the metal pin will punch through the grease and make an electrical

contact like wire wrap. But the grease surrounding the small

contact point will keep oxygen from degrading the electrical

connection. Note patent 5037566

Lubricating composition and method for making same is all about

keeping Oxygen out of the grease.

When received the LCD display backlight came on and the display

showed 2 rows of all black 5x7 dots and two rows were not lit at

all.

After removing the two main printed circuit boards and

reassembling the receiver normal operation was restored.

The problem was oxidation between the one or more cable connectors

and the mating contact.

When received the radio was DOA. After removing and

reinstalling all the modules in their sockets a few times each the

radio worked.

The problem was oxidation between the module pins and the sockets.

This antenna was installed quickly to do some tests on PRC-68 Family Radios. When

taking it down it was almost impossible to separate the mast

sections. The copper had oxidized inside the screw thread

joint and much heat and force was needed to get them apart.

After polishing the male and female copper threads Radio Shack

Lube Gel 64-2326

US

5037566 - Lubricating composition and method for making

same. "...provides high corrosion resistance due to the absence of

dissolved air and moisture.."] was applied to the joint before

mating the antenna sections and Coax-Seal (Radio Shack: 278-1645)

was used to seal the open part of the joint.

Lube Gel was also applied inside all outdoor RF coax

connections to keep water out of the joints and prevent

corrosion.

It may be that using Lube Gel in all of the above cases would

prevent a future occurrence of the same problem?

Lube Gel appears to be a modern snake oil that can prevent many

ailments.

After receiving this used but operational radio I cleaned it up

using Windex, a toothbrush and a Rag-in-a-box both outside and

inside.

As part of this process I found a number of screws that were

either very loose or about to fall out.

The lesson is to give a close visual examination and that can best

be done by cleaning.

The front panel had been bashed in. This broke a plastic

part that holds the radio buttons used to select frequency.

After removing and disassembling the front panel the plastic part

could be removed and epoxied back together using J B Weld.

The neon power indicator was held on with one of those flat metal

spring with teeth. The plastic part of the indicator was

broken by whatever hit the panel so the only thing to do was break

the plastic behind the panel. Hot melt glue attached the

front of the plastic to the panel and holds the neon tube where it

was. From the front it looks original. All of the

button caps were removed and cleaned. They had what may have

been tobacco smoke obscuring the numbers.

When received the phone did not work. Opened up the case and

disconnected the internal connector. Visual and olfactory

inspection showed nothing amiss. Reconnected the internal

connector and reassembled. Now phone works. the

connector must have had one or more poor joints. Note this

is a Gold plated connector.

It worked for about a year and it's dead again.

PP-8444A/U

Battery Charger arrived DOA from eBay

Was sold as looking good and "as is" so no complaint. After

some troubleshooting it appears that on both charger boards C5 a

Tantalum cap and U3 an MC34163 Inverting switching regulator have

failed. thus causing a short (<2 Ohms) directly across the 24

VDC input to the charger board. A shorted Tantalum cap was

the problem with the SG-1144 Signal Generator.

The power supply had a number of shorted Tantalum caps.

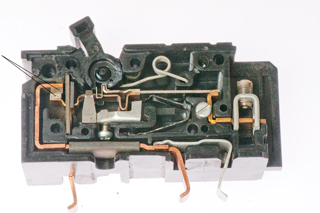

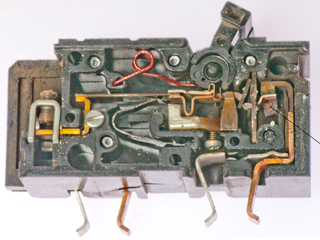

SB-22 Switchboard

Before cleaning the resistance on one of side of the "D" battery

holder was about 27 Ohms, way too high to pass the current needed

for the talk battery or the buzzer. After cleaning it was below

0.01 Ohms.

After sitting in storage for years with the batteries removed the

battery holder threads developed oxide. When fresh "D" cells

were installed the switchboard would not work. The fix was

to througherly clean both the male and the female threads of the

battery holder and then apply Contax

Oxide

Inhibiting Compound (contains castor oil and

carbon black)to all the threaded battery holder joints. I

got this bottle at the OSH store in Sunnyvale, CA.

There was a time where the U.S. National Electrical Code allowed

Aluminum wire in residences instead of Copper wire. When

joining Al and Cu wires a poor joint might result depending on how

the joint was made. To help solve this problem you can apply

Contax. So you'll find it in the electrical supplies section

of a good hardware store.

This unit arrived DOA. At the time I thought that it

was shipping damage (and that is probably the case) since the

other two boxed units that came on the same pallet worked fine but

this one out of the box was dead. Since it was no more than

parts, I took every module and board that could be removed out and

figured out all the connector and PCB pin outs. In order to

sell it as a parts unit it was reassembled and just for fun

powered up.

It now locked and started working. So cycling the

connections may have brought it back to life.

Hard Drive Failure

For awhile I was using removable hard drive "drawers" as part of a

back up plan. The idea was that you could clone the C: drive

onto another hard drive. Shut down the computer and move the

cloned drive to the C: slot and retire the old C: drive as the

backup. Then power up the computer and run on the new

backup. The beauty of this approach is that you know

immediately if the back up is good. The other hard drive

backup methods have a fatal flaw in that you only find out of the

backup is good after your main drive fails and then it's too late.

The problem is that the drawer caddy adds another electrical two

connections. The original cable from the mother board now

connects to the back of the cabinet that holds the drawer. and

there's a plug and socket the allows the drawer to mate with the

cabinet. Then there's a short cable inside the drawer

between it's plug and the hard drive.

A parallel ATA cable (IDE cable) has 40 (or in some cases 80)

separate electrical connections the number of connections goes

from 40 to 120. If any of these has a problem the data on

the disk can become bad.

So there's a huge reliability advantage to the new Serial ATA

(SATA) interface because it greatly reduced the number of

electrical connections.

A few months ago my 500GB IDE drive was nearly full so I replaced

it with a 1 TB SATA drive. Now I'm no longer using the hard

drive drawers. In the future I'll be going with only SATA

drives.

This is an in and out of circuit transistor tester. Although

the DC battery check works, the beta test appears dead. It

uses a 1 kHz signal to measure beta. The 1 kHz signal is

coupled in many places by electrolytic caps. There are 5

caps that are all 25 uF @ 10 Volts. The AC impedance at 1

kHz would be about 6 Ohms, but the ESR meter is showing as high as

46 Ohms, almost an 800% error! All the electrolytics in this

meter need to be replaced. After replacing the high

resistance caps it still does not work.

By starting with the schematic diagram and erasing all the switch

contacts and are not being used and then anything in series with

them the resulting schematic has missing connections. Very

strange. Although it may be that lines were erased that

should not have been, repeated audits have not found them.

If you have one of these that's working please let me know.

Dead CRT Computer Monitor

Symptoms: burning electronic part smell. Failure to turn on.

A

visual inspection found this burned out component. The

schematic symbol under it looks like the letter "Z". It's

located at the AC mains input to the power supply. Right

behind it is a bridge rectifier and a 330 uF cap. The coils

to the right are probably part of the line filter network.

The two blue wires go to the front panel, not sure why since

the front panel (left of photo) On-Off switch has a plastic

connection to the line switch (to the right of photo).

A

visual inspection found this burned out component. The

schematic symbol under it looks like the letter "Z". It's

located at the AC mains input to the power supply. Right

behind it is a bridge rectifier and a 330 uF cap. The coils

to the right are probably part of the line filter network.

The two blue wires go to the front panel, not sure why since

the front panel (left of photo) On-Off switch has a plastic

connection to the line switch (to the right of photo).

What is the dead part?

It might be series connected (inrush current limiting) or shunt

connected (overvoltage protection MOV).

When trying to trace the PCB wiring using the DMM in continuity

mode a chunk of the PCB (around the burned area) fell out.

So I've scrapped this monitor.

I'm thinking it may have been the problem or the cap behind or a

nearby cap may be bad. The ESR checker will be used, but the

first order of business is to find out what this is.

Note the rectangular black plastic part just behind the split

component. The solder connection looks like a donut, i.e.

it's not wetting the lead, a poor quality joint.

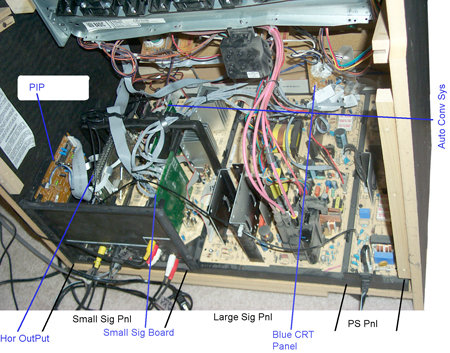

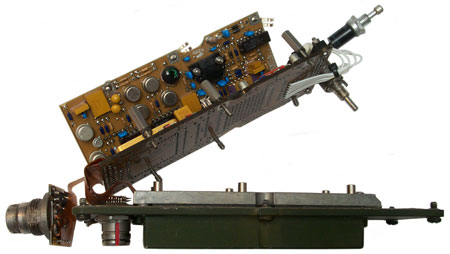

Philips 60PP9202 17 Projection TV

Sudden Red Convergence Problem

|

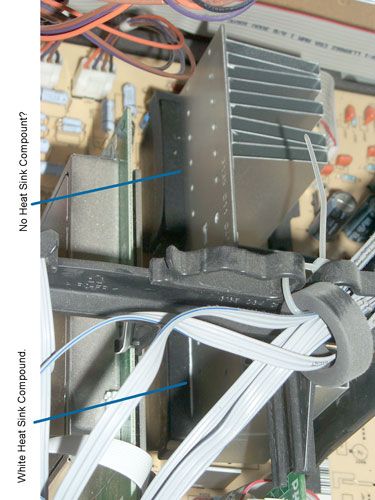

This is the main

board. The large fined heat sink holds the two

convergence STK392-120 ICs. Each of them and three

channels so it takes two for a balanced drive.

There must be a hundred cables that need to be removed to

get that board out of the set.

Beside each board connector there is a reference number

that can be written directly on the ribbon cables, but all

the others will need some kind of label.

|

|

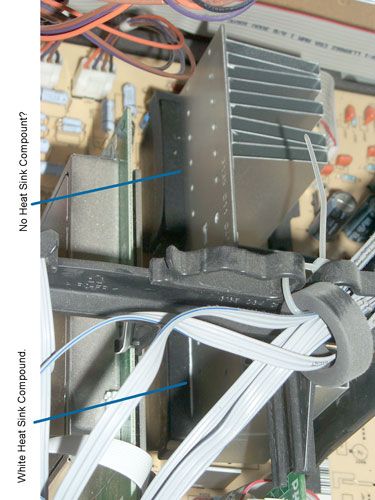

In the photo at left it

appears (needs to be confirmed after removing the

STK392-120) that no heat sink compound was used when the

rear chip was installed at the factory. The front

chip clearly shows a bead of white heatsink

compound. There is heat sink compound behind the

rear chip, just not as much.

It would be nice to have detailed instructions for the

replacement of the two convergence driver ICs and the

realignment. If you have it or know where I can get

it please let me know.

|

|

To remove:

I already had the large rear cover and the cover around

the three projection lens assembly removed and the panel

to it's rear, maybe or maybe not required for this.

remove rear connector panel. In addition to the

screws on the outside there are a couple on the inside and

the nut on the "F" connector.

Remove the centeral bridge to get better access for cable

removal.

Remove all the cables (seems like a hundred), labeling

them all so they can be replaced.

Remove (maybe 3 or 4_ screws holding down PCB.

Lift the tabs on the right and slide the PCB out the back.

The spring clips have been removed from the two

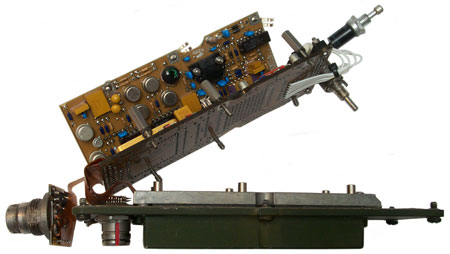

STK392-120.

|

|

Using solder wick AND

adding liquid flux the pins were easily desoldered and the

ICs just dropped out.

Breaking the plastic case shows the inside of the

STK392-120. Appears to be all discrete parts, no

ICs. Note the base is the aluminum plate heat sink.

The leads got mangled in the process of removing the

plastic case.

|

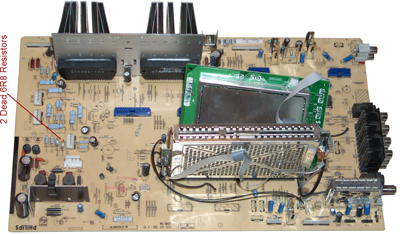

Note the lower

resistor is marked 6 (the rest has been cooked off) the

others nearby are marked 6R8 or 6.8 Ohms. There are

12 of these always in pairs. The pairs are wired in

parallel and so measure about 3.4 Ohms true or 3.6 on the

DMM because of the test lead resistance. Note the lower

resistor is marked 6 (the rest has been cooked off) the

others nearby are marked 6R8 or 6.8 Ohms. There are

12 of these always in pairs. The pairs are wired in

parallel and so measure about 3.4 Ohms true or 3.6 on the

DMM because of the test lead resistance.

These measure in the Meg Ohms, i.e. totally fried.

Now 27 Jan 2009 to wait for the resistors to be

delivered.

The two fuses tested good.

The resistors are grouped near the three connectors

for RED, BLUE and GREEN, not the STK392.

|

After replacing both

STK392-190 chips the TV was just as bad as before.

It was much faster to pull the main board since all the

cables were labeled.

With no documents it the drill was to check all the

resistors. These were found on the other side of the

board from the STK392 near the connecor marked RED.

|

Installing

the two 6R8 resistors fixed the convergence problem.

But while doing the convergence using the manual procedure

with a grid of 5 x 7 "+" marks and watching some

DVDs a blue halo was noticed surrounding bright

subjects. This is very likley due to contaminated

coolant on the blue CRT.

|

|

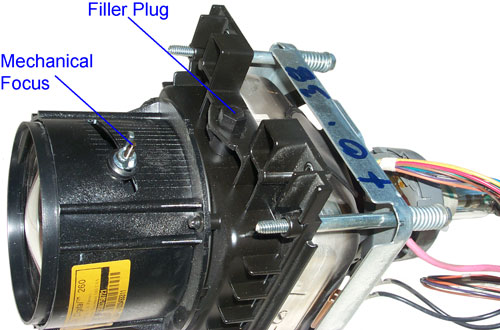

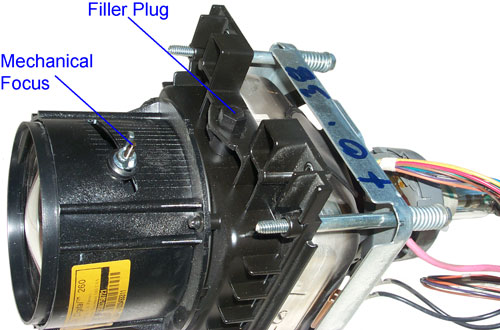

It looks like the complete

blue assembly can be removed by removing the 4 screws from

the sheetmetal bracket and disconnecting all the cables

and unplugging the PCB.

All that has been done, except removing the anode HV lead

at the main PCB rather than at the CRT.

How to unplug it?

|

|

Philips 60PP9202

Blue CRT Assembly

The anode HV wire unplugs from the three way HV splitter

and the yellow ring stays as part of the splitter.

Anyway that's what I hope.

Just above the lens, facing to the right is a cover held

in place by 4 screws. This is the bladder

compartment. At it's center is an inspection hole.

The blus stripe on the connector next to the HV wire was

put on by the factory.

|

Philips 60PP9202 Blue CRT

Cooling Fluid Filler Plug

The filler plug is opposite to the bladder.

What does "+0.38" Mean?

Let me Know.

The Yellow sticker says:

Delta DigitalTM 260

Covered by U.S. Patents

3M Precision Optics Inc

p/n 313503750721

The fluid is just under the plug so a way to suck it out

would be good to avoid spilling it.

"Projection Tube Coolant" is the title of the eBay item

that's on order.

|

|

Philips Blue CRT Coolant is

Cloudy

The photo does not show the backscatter as well as you can

see it with you eye. As the Mini Maglight is

focused you can see the bright and dim beams change shape.

The thick fluid also has a yellow tint.

Remove plug, place small finger over hole, ,turn upside

down over tray, remove finger and while tipping slightly

in all directions empty fluid.

|

Denatured

Alcohol is no longer a drug store item. But is

carried by paint stores like Kelly More. It's the

solvent recommended in the factory manual for cleaning the

fluid chamber. Rather than disassemble the chamber

I'm going to rinse it many times using the Denatured

Alcohol. Three times yesterday. Leaving the

plug off so it can evaporate. An ear irrigation

rubber bulb makes a nice tool to put the Alcohol into the

small filler hole.

|

9

Feb 2009 - the bottle arrived and is labeled "Fluid

Coolant" not "Projection Tube Coolant". I

wonder if it's used in some other application?

The ear irrigation rubber bulb is a good tool to put the

fluid into the small hole. If you look into the lens

you can get a very good idea of how much fluid is there

from maybe 10% to 90% of capacity. When the

chamber is almost full you can see the distortion on the

surface as new fluid is added. The plug has a

projection that displaces some fluid when it is installed,

probably as a way to prevent over filling.

It only takes a few minutes to reinstall the CRT assembly

into the set since all that's required is to put in the 4

screws that hold it in place and plug in the cables and

the small PCB.

Now when a DVD starts the blue "DVD" no longer is

surrounded by a blue cloud and at the top of the screen

there are horizontal bands of blue that are visible (which

before was just a blue fuzz ball). The optical and

electrical focus on blue needed tweaking and now the blue

convergence can be done. The only problem left is to

tweak the blue intensity. The picture looks great

and skin tones are great.

10 Feb - A helper can push the navigation ring on the

remote to keep the manual multi point convergence big +

moving (to prevent the timer from turning it off) and

covering one of the two active CRTs then you can adjust

the electrical and mechanical focus on all three

tubes. By watching a good movie the blue intensity

was adjusted then after watching more movie it was

tweaked. Now the image is as good it gets,

much better than prior to the red convergence failure.

Pressing and holding Mute on the remote and pressing any

button on the front of the TV causes it to go into User

Service Mode and no error codes were shown.

|

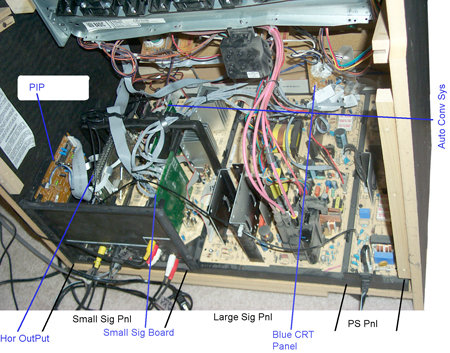

Major

Components

|

After reading

about the failure of the convergence amplifier ICs in projection

TV sets this seems the most likley cause of the sudden red color

failure.

The Philips web page will not sell me a service manual, only

"authorized" dealers can buy it.

Now looking for a source of the STK392-120 chips. I found

two eBay sellers of this chip.

One offers a 2 pack for $12.99 but does NOT mention the brand

name.

The others offer them for $12 to $15 each including USPS mail

delivery, I got a couple of these.

Home Theater Shack -

Link to my post

#222 asking about the Service Manual and where to get the

chips. Post moved to Philips

60PP9202.

The fundamental problem may be the choice of thermal grease.

The early formulations have a thermal resistance vs. time

degradation that the newer types no longer have. For example

Wakefield 126 (accessories.pdf

1.3 MB) Thermal Joint Compound is twice as good as the old 120

compound after 6 onths of cure time. Found this when working

on a 7 Watt LED.

Ohm Meter Readings on the STK392-120

Pin

|

Function

|

7405 rear

|

7404 front

|

1

|

Sub Gnd

|

0

|

0

|

2

|

Gnd

|

0

|

0

|

3

|

Muting

|

1.6M

|

10k

|

4

|

-PreVcc

|

1.4M

|

1.4M

|

5

|

+PreVcc

|

2.6M

|

2.6M

|

6

|

Ch1 +In

|

3.2k

|

3.2k

|

7

|

Ch1 -In

|

3.3k

|

3.3k

|

8

|

-Vcc1

|

1.5M

|

40k

|

9

|

Ch1 Out

|

104

|

104

|

10

|

+123Vcc

|

0.5

|

0.5

|

11

|

Ch2 Out

|

104

|

104

|

12

|

-Vcc2

|

380k

|

1.4M

|

13

|

Ch2 -In

|

3.3k

|

3.3k

|

14

|

Ch2 +In

|

3.3k

|

3.3k

|

15

|

Ch3 +In

|

3.3k |

3.3k |

16

|

Ch3 -In

|

3.3M

|

3.3k |

17

|

-Vcc3

|

2.4M

|

2.7M

|

18

|

Ch3 Out

|

3.2M

|

104

|

All the outputs are 104 Ohms except for 7405 (rear IC that had

minimal heat sink compound) which is 3.2 M Ohm. It's blown

open and Ch3 is probably Red. Note that pin 18 is close to

the center of the heat sink and so will have some heat from the

front chip. If heat is the problem then you would expect

Channel 3 of the rear chip and/or Channel 1 of the front

chip to go since they will be the hottest ones.

The other values are marked red because they are different for the

front and rear ICs.

Dec 2009 - When upgrading my Home

Theater and watching YouTube the blue was way off

convergence and the red was a little off. It turns out that

the new A/V receiver was feeding the projection set 1080i video

and when the repair was made the alignment was not done for that

resolution. While feeding the set with a YouTube video the

multipoint red and blue alignments were done requiring a number of

iterations. After watching a few YouTube videos another

alignment was done.

When a Blu-ray disk is played and the output fed to the A/V

receiver using component video the projection monitor is fed 1080i

video. The image is FANTASTIC!

Service Manual

Available as .pdf from Manual

Zone - Has Parts lists for 82 model numbers but there may be

many duplicates. 1,848 pages.

Patents relating to Rear Projection TV

by 3M Innovative Properties Co (seem to be about the screen

not the optics)

6163402 Rear projection screen, 3M Innovative Properties Co, Dec

19, 2000, 359/443 ; 353/74; 359/454; 359/460 - made for HD

TV

6204971 Glass microspheres for use in films and projection screen

displays and methods

6317263 Projection screen using dispersing lens array for

asymmetric viewing angle, 3M Innovative Properties Co, Nov 13,

2001, 359/443; 359/460 -

6417966 Rear projection screen using internal reflection, 3M

Innovative Properties Co, Jul 9, 2002, 359/453; 359/460 -

6449089 Rear projection screen with enhanced contrast, 3M

Innovative Properties Co, Sep 10, 2002, 359/454; 359/460 -

6515798 Rear projection screen, 3M Innovative Properties Co, Feb

4, 2003, 359/443; 359/449 -

Capacitor Failure

The idea with a capacitor is to have

capactive reactance that's low compared to the rest of the

circuit. The equivalent series resistance (ESR) of the

capacitor should be considerable lower than it's capactive

reactance.

Xc = 1/ (2 * PI * F * C). Values shown in table below are at

60 Hz.

Capacitors - new web

page

EVB

ESR Only Tester

I have made some modifications on the stock tester so that it can

be used to measure the ESR of batteries.

(1) The two large protection diodes need to be removed from the

PCB. They are located near where the banana jacks are wired.

(2) A SPST normally open push button switch is added near the tip

of one of the test leads and in series with the lead. Across

the switch place a 470 ohm resistor. When the probes are

first connected to a live battery the 470 Ohm series resistor pre

charges the internal non polarized blocking caps without hitting

them with a really fast rise time pulse, thus tending to protect

the internal circuitry.

On the face of the meter is a table showing normal ESR values for

capacitors as a function of capactance and voltage rating.

|

10 V

|

16 V

|

25 V

|

35 V

|

63 V

|

160 V

|

250 V

|

1 uF

|

x

|

x

|

5

|

4

|

6

|

10

|

20

|

2.2

|

x

|

x

|

2.5

|

3

|

4

|

9

|

14

|

4.7

|

x

|

x

|

6

|

3

|

2

|

6

|

5

|

10

|

x

|

1.6

|

1.5

|

1.7

|

2

|

3

|

6

|

22

|

3

|

8

|

2

|

1

|

0.8

|

1.6

|

3

|

47

|

1

|

2

|

1

|

1

|

0.6

|

1

|

2

|

100

|

0.6

|

0.9

|

0.5

|

0.5

|

0.3

|

0.5

|

1

|

220

|

0.3

|

0.4

|

0.4

|

0.2

|

0.15

|

0.25

|

0.5

|

470

|

0.15

|

0.2

|

0.25

|

0.1

|

0.1

|

0.2

|

0.3

|

1000

|

0.1

|

0.1

|

0.1

|

0.04

|

0.04

|

.15

|

x

|

4700

|

0.06

|

0.05

|

0.05

|

0.05

|

0.05

|

x

|

x

|

10000

|

0.04

|

0.03

|

0.03

|

0.03

|

x

|

x

|

x

|

Note that the

Impedance of all capacitors

is a function of frequency. As the frequency goes up the

capacitance will decrease because of the inductance of the leads

and maybe the capacitor itself. Typically the smaller the

value of capacitance the higher in frequency it's still a

capacitor. So it's common to see a number of capacitors in

parallel.

Electrolytic

It's the nature of electrolytic

caps to have the electrolyte evaporate. How fast that

happens depends on how well it was sealed. Another problem

showed up around 2002 when a defective electrolyte was used in a

very large number of caps resulting in failures after 250 or

more hours of actual operation.

Low-ESR

Aluminum Electrolytic Failures Linked to Taiwanese Raw

Material Problems. The failure mode is to blow the

vent cap and spew electrolyte. The electrolyte will damage

printed circuit boards beyond repair and that can lead to smoke

and or fires. Electrically the cap looks like an open and

in some cases the guts are blown out of the can and it's

literally empty.

#

|

Cap uF

|

WVDC

|

Xc60

|

ESR

|

ESR/Xc %

|

0.5*C*V*V

|

The

formula columns are an attempt to come up with a way to

predict the ESR for a given chemistry cap. Not

working yet.

|

1

|

40 |

200 |

66

|

0.64 |

1

|

0.8

|

2

|

500 |

50 |

5

|

0.19

|

4

|

0.625

|

3

|

2200 |

6.3 |

1.2

|

0.23

|

19

|

0.04

|

4

|

39 |

16 |

68

|

0.30

|

0.4

|

0.004

|

Tantalum

Tantalum capacitors offer a higher

C * V product than electrolytic capacitors in the same

volume, or more commonly in a smaller size package. When

introduced they were adopted by the military and commercial

electronics industries. But if improperly installed

(polarity reversed) they behave more like firecrackers and

immediately explode. Also if subjected to spikes of

voltage or current they will be degraded or fail. The

failure mode is to short out. This causes some up stream

component(s) to fail by burning up possibly starting a fire or

destroying a printed circuit board.

|

These are tear drop or

dipped Tantalum caps and are the type I've seen most as

dead shorts.

#

|

Cap uF

|

WVDC

|

Xc60

|

ESR

|

ESR/Xc %

|

5

|

10

|

35

|

265

|

1.2

|

0.5

|

6

|

10

|

25

|

265

|

0.35

|

0.1

|

|

|

Trimble 16768-80 SLGR GPS

Receiver Power Supply

#

|

Type

|

uF

|

WVDC

|

ESR

|

C5

|

Tan

|

10

|

35

|

0.42

|

C1

|

Al El |

220 |

63 |

0.39

|

C4

|

Tan |

220

|

10

|

0.05

|

C3

|

Tan

|

?

|

?

|

0.17

|

C4 Hermetically Sealed Axial Tantalum

marking:

M39003

09-0221J

+220uF

10% 10 V

31433

9101AM K

|

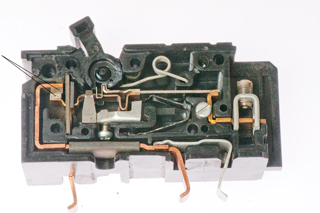

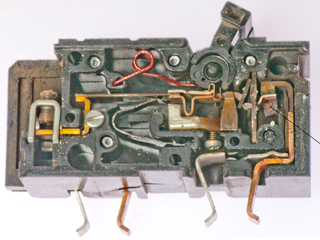

PRC-104A Panel Short

|

|

|

PRC-104A (RT-1209A)

Front Panel Shorted Cap(s)

Marking on the rear cap is:

CX06M685M

8848VME

Dipped Radial Tantalum Capacitors 35volts 6.8uF 20%

Capacitor, tantalum,

6.8 uF, 20% Tol,

-55/+125C, 35V@85C, 23V@125C,

E,

Micro-Miniature: Size E, (E x 3.3" x 7.87"

LxTxH),

Pitch is 0.2", W=0.228", T=0.126", H=0.30"

Bulk, Bag (180 pcs),

6% DF, 2.5 Ohm ESR, 3 uA Leakage

There are two of these caps connected in parallel and

they are across the main DC power supply.

Another PRC-104A panel had this exact failure.

A voltage rating of 35 VDC maybe is too close to the

input voltage range of 9 to 32 VDC?

A 50 VDC 6.8 cap is available T491D685M050AT

that might fit the space.

|

After

replacing the two caps the blown fuse problem has gone

away.

Pressing the LIGHT button turns on the back light.

But the LCD is blank and the handset does not have white

noise.

Bent Connector

|

|

Visual inspection shows

that he AUDIO connector has been bent or hit causing it

to sit at an angle and it's support PCB has broken

solder joints on the ground pins. |

The audio

connector has been separated for inspection. The

two new Tantalum capacitors are the round yellow ones. The audio

connector has been separated for inspection. The

two new Tantalum capacitors are the round yellow ones.

|

PRC-104A Cracked Front Panel (2 places)

|

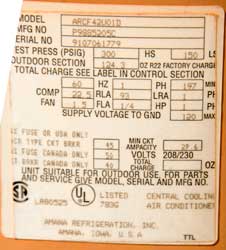

Weather

When anything is outside the elements (heat, cold, sun, rain

&Etc.)can cause failures.

Harbor Freight 93068

March 2016 - The outdoor unit stopped working after a lot of

rain.

This is a battery powered outdoor PIR sensor with an indoor

audible alarm. To open it up remove the top center screw

then the battery cover and underneath remove 2 screws.

The problem seems to be that there's rust on the surface of the

PIR sensor. Using a Q-tip and tap water I cleaned the

sensor and it now seems to be working.

Before reassembling I coated the rubber O-ring that is supposed

to seal the two parts of the housing with Silicon grease.

Fig 1

|

|

This may be the A-6F

Classic.

Fig 1

|

This bird feeder is probably 30 years old

and been outside in Northern California all that time.

I think what did it in was the sunflower seeds got wet and

then froze. The expansion broke the tube at the

bottom.

A replacement tube is on order.

The seed

tray at the bottom was an option. It catches

some of the seeds that the birds would otherwise knock to

the ground.

An excellent value considering how long it lasted and that

it can still be repaired.

|

|

Fig 2 This Droll Yankees bird feeder was in

the garage all dirty. After taking it apart and

cleaning, it's now back in service.

The green parts are metal. Only the tube and black

bottom cap are plastic. Not all parts shown.

|

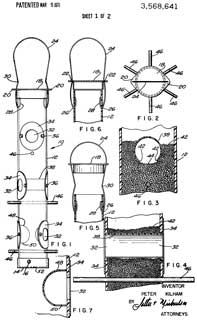

|

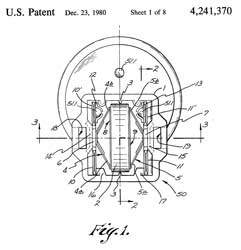

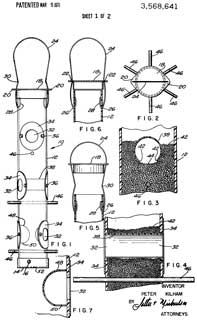

3568641

Bird feeder, Peter Kilham,

(before Droll Yankees), App: 1969-03-03, 119/57.8; D30/127 -

The design is over 50 years old.

|

Static & Electrocution

Electrocution

Often static electricity is blamed for what I call

electrocution. For example, I was asked to investigate why

the yield was very poor on an expensive polar discriminator

assembly that used four back diode detectors on each housing.

Static discharge was the assumed cause of the problem, but

the real problem was a soldering iron that had about 15 VAC on

the tip. Back diodes can be blown with only a few volts.

The work bench had maybe a half dozen soldering irons (all

expensive anti static grounded tip type) and only when the

defective iron was used would the diodes be blown.

Static

Some definitions

Antistatic: Preventing or

inhibiting the buildup of static electricity.

Since static electricity is

generated by moving electrons from one insulating material

to another the current involved is very small so a high

value resistor between the two objects can easily equalize

the voltages and prevent buildup. A pure plastic bag

that can generate static electricity can be treated in a

number of ways so that it has a high resistance and then

will not generate static. This is an anti static bag.

Electrostatic Discharge (

Wiki

Talk): The sudden and momentary electric current that

results when an excess of electric charge, either stored on an

electrically insulated object or on an isolated conductive

object, finds a path to an object at a different electrical

potential (such as ground).

Getting shocked in a warm room

in the winter time when touching a metal object is because

of ESD.

Lightening is an example of ESD.

It's very important to see the

distinction between these two ideas.

I sit on a chair with plastic wheels in a room with wall to wall

carpet. I used to use a "chair mat" to get a hard surface

so the chair wheels would roll, but plastic wheels on plastic is

a static generator and often I would get a static shock.

Using antistatic spray would help but was not a cure.

Placing a sheet of plywood over the mat (could have

removed the mat) solved the problem.

When working on a PC I leave the power cord plugged into the

wall. This has a danger factor in that the power switch

has hot line voltage and maybe some spots on the power supply

are line hot. But it also connects the chassis to line

ground so that if you touch the chassis before you touch any

static sensitive device the static will be grounded.

Wrist straps are not good grounds, but rather have a 1 to 10 Meg

Ohm resistor in series between the human and ground. This

way you are not grounding someone and making a human

electrocution possible. If you want to make your own

ground strap by using a piece of copper wire and a ground lead,

be sure to insert a 1 MegOhm resistor in series.

Many companies that work with static sensitive components, like

microwave parts or disk drives, have special flooring that is

conductive and the workers wear shoes that are conductive or use

heel straps that make a high resistance path from the floor to

the ankle. This way a person walking does not build up a

charge. Also the chairs and stools have grounding chains

always in contact with the floor so a moving chair does not

generate a charge.

When packaging a static sensitive component many people make the

mistake of thinking that using an "antistatic" bag will protect

the component. THIS IS NOT THE CASE. An "antistatic"

bag will not generate static but does not protect from

static.

It

is easy to destroy the component while it is in a sealed

"antistatic" bag. Just walk across a carpet on a dry

day and touch the top of the bag while it is sitting on a

metal work bench.

The proper way to protect the static sensitive component

is to wrap it in Aluminum foil or use one of the conducting

Faraday cage type bags.

PS

Magazine 2004 Issue 623

page 42 has published this information about what

antistatic means. (PS I'm in Ukiah, CA, not San Diego)

EEVblog

#3 – Anti Static Myths Busted -

Office chairs that have plastic wheels rolling on carpet

protectors make excellent static generators. They are a

real problem around computers. It's better to get a sheet

of 3/4" plywood for the chair to roll on.

This

$0.70 Component SAVES your Circuit?! EB#59, 12:16 - TVS

Diode (Wiki,

P6KE15A),

MOV (Wiki: Varistor),

GDT (Wiki: Gas Discharge Tube,

Telephone Protector)

Printed Circuit Boards

A way to get a double sided board with vias is to use Express PCB. They

have a prototype service that will supply 3 boards that are 3.8 x

2.5 inches and have tin-lead reflow but have neither Silk

screening, solder masks, routing nor multi-layers. There are

a limited number of drill and pad sizes. You can put a

number of smaller boards on one and separate them yourself using a

Tungsten carbide tipped scriber (General Tools

Model 88CM, Catalog No. GEN-31116 ). A straight edge is

needed for the first pass but all the succeeding passes are in the

groove.

In the 1960s we used shoe eyelet's to connect the top and

bottom PCB traces in double sided boards. They were

installed and formed using a motor powered machine then hand

soldered. This was a military approved way of PCB

construction and much easier than soldering a wire and cutting

off both ends.

2002 - update on cutting printed circuit boards. I got a

single speed skill saw at Wal-Mart, chosen for it's low price

and that fact that it had a couple of nuts as part of the flat

surface. By drilling a hole through the 1" thick workbench

top and making a short slot for the blade, then mounting the saw

underneath the workbench using a couple of flat head screws,

with only the blade sticking up through the slot I now have a

reciprocating table saw. By using a fine tooth metal

cutting blade you can separate 25 to 100 PCBs. This bench

mounted $10 saw turns out to be quite handy. The screws

that pinch the blade turn out to be an M4 thread and have been

replaced. It takes a lot of finger strength to cut small

boards since you need to hold them down very firmly or they will

jump up and down with the blade. It makes a lot of dust

that you should not breathe. It takes a little more than

50 mils for the saw kerf.

2006 Update - A small 8 inch Mini Shear

Break designed for working sheet metal does a nice job of

cutting 1/16 inch PCBs. Although I think I know why the

first one is not broken waiting for parts to arrive from China,

I've received an email from another user that said his would not

cut boards out of the box.

Replacing soldered in ICs

After having identified a bad IC

that's soldered into a PCB I used the following procedure.

Cut all the IC leads using diagonal cutters. It took a

couple of passes to get them all cut on one side of the

IC. Then bend the IC up and unsolder and pull each lead

one at a time. Then press the IC down and cut and desolder

each of the pins on the other side. This destroys an IC

that was bad already but greatly reduces the chances of damaging

the PCB.

3 May 2006 - Next using a solder sucker clean out all the

holes. Install the new IC and solder in place. This

may not be so easy. Sometimes neither solder wick nor

solder sucker will get the solder out of the hole. If a

piece of wire that's the right size for the hole is chucked into

a Dremel tool then cut off so that only a board thickness plus a

little is above the chuck face. It can be used as a drill

bit on the highest speed. Another option that has also

worked for me is to use a sewing needle held in a pin vise to

push a hole into the solder, sort of swaging.

Using Solder Wick

6 May 2006 - If just prior to using the solder wick you wet

about 1/4" with RMA flux it will work much better. This

may be for two reasons. First the liquid conducts the heat

better than air and second, the flux cleans the solder wick of

oxides allowing the solder to bond easier. This makes the

difference in being able to get solder out of small diameter

holes or not getting it out and needing to drill as above.

Flux

The key property of

solder flux is that it's boiling point is higher

than the melting temperature of the solder.

This makes for excellent heat transfer. The

shape of a soldering iron tip is typically conical

or cylindrical and so touching the iron to a wire or

circuit trace makes for a small contact area and

poor heat transfer.

If a small amount of flux is applied and the iron

located where flux is present then you have much

better heat transfer. If there's a hole with

solder and a component lead you need to fill the

hole with liquid flux to transfer the heat to the

solder. If you just flux the solder wick you

may or may not be able to get the solder out of the

hole.

Flux pens and a handy way of applying liquid flux,

but don't order them on the same order as other

items because it will slow down your whole order

since they are shipped as a hazmat item.

|

This is the

construction of the A.C. Power cord for the

M455-1 Power Supply. The

connector was second hand, i.e. all the cups were full of

solder. The wick was flat and a little wider than the O.D.

of the pin but using tweezers it could be formed into a shape

that would fit into the solder cup (after using the wick in the

normal way to get down to the solder cup). Then using a

very pointed iron (the one used for

SMT

soldering) and trapping the wick between the iron an the

protruding part of the cup the solder was sucked completly out

of the cup.

Flux & Solder Wick

It's very important to add liquid flux to the solder

wick to transfer the heat. This will make the

difference between no wicking and wicking!!

|

The "A" pin at about 2 o'clock is the one that's been cleaned,

no point in doing pins that aren't going to be used.

The black jaws are on a Panavise Jr.

Also when using shrink tubing in very tight quarters like this

don't use a size that's a tight fit because when the wire

insulation distorts you will not be able to pull the tubing over

the joint. A pair of tweezers was used as a heat sink to

keep the shrink tube from shrinking. The tweezers were

held closed by a spring like used in the

257477BA Battery Adapter.

Here

the Panavise Jr. is tipped on it's side and the rotation of the

ball clamp has been adjusted so that there's a three point

support (the base, the end of the adjustment arm, the tip

of a jaw) that's stable.

This is a great way to hold connectors while they are being

assembled.

Soldering Surface Mount Devices - seperate web page on

Surface Mount Technology

Soldering Iron Tip Maintenance

When finished using a soldering iron I used to clean the tip and

power down the iron. This results in the tip oxidizing and

getting pitted. Much better to clean the tip and put a big

glob of solder on it just prior to power down. Also the

modern tips come with a silver colored plating, they are not raw

copper and this helps maintain the tip, so these should not be

filed.

Reverse Engineering

Naming

Most of the equipment that I have

reverse engineered made use of printed circuit boards. If

the board has part ID information you can use the same part names,

but if it does not (most of the time) they you need to name each

part as well as have a way to identify each lead. Lead

identification for ICs is easy since they have standardized pin

numbering, diodes have an anode and cathode, but resistors and

other parts don't have lead specific markings and so you need to

keep track of which end goes where. This can be done by

using a flat bed scanner to make color images of each side of the

board and then adding part names, like shown in manuals.

Conformal Coating

Often it's necessary to use a

continuity checker (beep Ohms mode on a DMM) to find out what's

connected to what. This is especially true for multi layer

boards. When working with military boards you will find that

they often have conformal coating that is thin and

transparent. So when you place a probe tip on top of what

appears to be nice shinny solder you will NOT make electrical

contact. A quick check is to put both probes on the same

pad, yet not touching each other. If there's no continuity

then you know you're working on a coated PCB. One way around

this is to push and/or rotate the probe to punch through the

coating and into the solder, but the same pad may need to be

probed many times and this really chews up the pad. A better

way is to use a large sewing needle held in a machinist's pin

vise. The meter probe can be put into the hollow metal

handle or connected with a clip lead.

BEEP Mode of DMM

The DMM may BEEP when the connection

is not really a metalic path but instead is a low resistance

path. So it's better to not use the beep function and

instead look at the Ohms reading.

Caution

When reverse engineering some thought

needs to be given to possible DC shorts. When working on the

FS5000 Spy

Radio I smoked a PCB trace that was on one of the interior

layers. This could have been avoided by fusing my test

fixture DC power leads (both the hot and ground).

Cable Testing

When reverse engineering a cable be

sure to look for jumpers that connect multiple pins on the same

end of the cable. These will show up if you test all

possible combinations of pins at both ends of the cable.

Loctite

Loctite is great for keeping screws from coming loose,

BUT should not be used near plastic parts. For the very

first production lot of my 2577BA

Battery Adapter I used Loctite 222 on a 6-32 screw that went into

an Aluminum spacer. BUT the 1/8" thick plastic sheet between

the two showed severe cracking when the Loctite set up and the

whole batch had to be scrapped. I think what happened was

some Loctite got into the space between the screw and the plastic

and when it set up it expanded and destroyed the plastic.

Needless to say I don't use Loctite in this application.

Rubber Parts

Rubber (and synthetic equivalents) biodegrade. Air

and/or water will cause them to disintegrate. Insulation

will turn to dust and hoses, gaskets, O-rings, etc. will

fail. In older automotive applications this is the most

common failure mode I have seen.

The O-rings in the U-229 connector get hard and/or

develop cracks when they age. This makes it difficult to

install/remove them.

A similar thing happens to the O-ring that seals the battery

magazine to the DAGR GPS receiver.

My 1929 Rolls Royce and the 1934

Rolls Royce used steel tubing between the vehicle frame

and the engine where today a rubber hose is used. They did

this by forming 3 or 4 turns about 3 " in diameter so that the

tubing would never be stressed past it's elastic limit as the

engine rocked back and forth. Of course the engine did

this only on acceleration or engine braking, when idling you can

balance a Nickel on top of the radiator.

The O-rings between the steel cylinder sleeves and the aluminum

block of the all the RR cars with a V-8 engine is a real

disaster. It's a certainly that one of the huge number of

rubber hoses carrying water or the rubber seal in the water pump

that also has to act as torque stop, will fail while you are

under way resulting in the engine block over heating.

Overheating those cylinder seal O-rings results in failure to

seal the water or oil. If it's the upper O-ring that

failed you will get water coming out of the weep holes in the

block since there are two O-rings at the bottom, the lower

O-ring seals out crancase oil, so if oil is coming out the weep

hole it means the bottom O-ring has failed. Needless to

say replacing the O-rings requires major engine

work. If the aluminum block that's about 1/8" thick

between cylinders cracks then it can NOT be welded since the

aluminum is plastic impregnated. But you might be able to

use an epoxy, didn't try that.

Bonding

Loctite

404 super glue can be used to join rubber parts. See:

YouTube: AVE: Make

any size O-ring, 2:13 - use Acetone to clean first.

Plastic Parts

If you search this page (CTRL<F>plastic) you will get a

lot of hits. While plastic is much lower in cost than

metal it does not last. Maybe there's a failure mode

that's similar to how rubber parts biodegrade.

Modern cars use a lot of plastic parts. The 1975 Volvo

has a plastic radiator but it's much more fragile than a metal

radiator. A similar thing happened with the Mercedes C230

plastic water manifold.

One of my pet peeves is not knowing how a manufacturer is

trading off reliability

and cost. That's to say some products are designed

with a Mean Time Between Failures of say one year while a

similar product my have a MTBF of five years. I'd

like to know the MTBF for high value products I buy so I could

decide which one I'd like.

Another factor is the ability to repair the product.

There are tow aspects to this. One is getting access to

the information needed to make a repair. This is being

fought in the courts see for example Apple and John Deere

tractors. The other aspect is some high end products, like

large flat screen TV sets where the ICs are custom made for a

particular model and there are no replacement ICs. If one

burns out then you need to throw away that product. See: Throw away

products.

Car Radio Knob Broken

There are small knobs that can be

popped out and then pulled out to set balance, bass and treble

settings. The plastic knobs seem to fall apart.

Repaired using J-B Weld epoxy being careful to keep it out of the

central hole. You can see some gray epoxy in the after

photo.

Cleaning

In order to make images of equipment I use a digital

camera or color flat bed scanner.

Both of these methods show up every spec of dust so cleaning is

needed to get good images.

Dirt

Dirt is the most common thing that needs to be removed

so the first cleaning step us to use water to wet the

dirt, a tooth brush, tooth pick, small brush, pipe cleaner to

scrub a little and a clean dry paper towel or tissue to wipe dry

and clean. Often knobs need to be removed to clean under

them. Engraved labels often have dirt covering the white

paint and need extra scrubbing.

Very Old Masking Tape

DE-Solv-It , Contractors' solvent available at K-Mart

- removed tape from a BC-611 radio

that nothing else could touch.

Tape adhesive

This

web page has a number of methods to remove tape adhesive as

well as other stuff.

Goo

Gone™ (Magic

American Corp.- Cleveland OH) has received a number of

recommendations on the Tek list server also works for decomposed

foam.

Rust

Oxygen, moisture and about

anything can combine to make corrosion. There are many

commercial rust remover products on the market. Many use

phosphoric acid. (Wiki:

Rust,

Rust

Remover). Renaissance Metal De-Corroder says it's made

of : Amine comples of hydro-oxycarboxilic acid. But the only

references to the key indegrient are ads or references to this

product. It has the look and feel of phosphoric acid.

Available from the Gemmary.

If paint primer is applied to bare metal it affords NO protection

from rusting. Primer is by design a porous coating so the

the paint overcoat will bond well. Leaving a car outdoors

with just primer is a great way to rust it (ask how I know

this). The second time I used a special paint made for ships

called

Corroless.

I picked this brand after reading the paint shoot out test results

in Skinned Knuckles magazine since it got the highest

ratings. Rustolum and POR15 were not as good.

I've

recently been doing things that involve metal working and a number

of times I've come across vapor phase rust prevention (aka:

Volatile Corrosion Inhibitors or Vapor Phase Inhibitors)

papers. There's a brown sheet of paper behind the plastic

laminated cal certificate in the box lid of the

pin gauges. That's the

special paper. My local machine shop ships metal parts to me

with some of the paper in the packaging. It has some shelf

life so is not a permanent solution, but one worth knowing about.

4604227

Vapor phase and surface contact rust preventive composition,

Stauffer Chemical Co, Aug 5, 1986, 252/389.2 ; 252/389.61;

252/392; 508/399

Protective Packaging

carries

moisture

barrier bags and

Vapor

Corrosion Inhibitors paper. Their web pages have a lot

of good info.

When rust forms in a

threaded fastener

it becomes very difficult to remove the fastener. Many

people use WD40 but that's the wrong thing. WD stands

for Water Displacement which is what it was made to do. For

getting stuck nuts, bolts or other items loose a penetrating oil

like

Kroil, is what works

best.

For removing rust from metal parts that are not to be painted

consider

Evapo-Rust.

For a user report see

VY2AC on Prince Edward

Island - Ridding Parts of Rust!

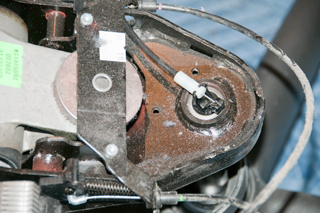

Lawn Mower (Scott's Model 22815x7A)

I put this article just below Rust

because that's one of the problems the lawnmower had after sitting

outside for a number of years.

This is a self-powered walk behind lawnmower with a vertical shaft

engine and single cutting bar. 6.0 HP B&S 4-cycle

engine.

There were a number of problems:

1) When the starting cord was pulled it failed to retract.

It turns out nothing was broken it was just a lot of friction

stopping it from retracting. The fix was to squirt some

Kroil penetrating oil into the joint between the rotating part and

the fixed part (a circle about 5" in diameter). This

probably could be done without any diss-assembly.

2) The drive belt had many cracks and broken parts and was very

stiff and needed to be replaced.

37x105, John Deere p/n: M77167

3) The drive axle was frozen (would not turn, would no come out to

allow Removing and Replacing the drive belt). It was

necessary to remove wheel support plates to free the axle.

4) the bolts holding the wheel support plates were frozen (rusted)

together and Kroil did not help so when torque was applied one

bolt snapped, so 4 replacement bolts and nuts were purchased along

with the new drive belt. Loctite 222 was used when

installing the new nuts and bolts rather than using lock washers.

5) the teeth on the inside of one of the drive wheels have been

almost all chewed off. I've ordered a couple of new wheels

from eBay using the B&S p/n 672441.

Storage

When in storage anything is subject

to oxidation, humidity and temperature cycling. Military

packaging typically involves sealing the product in an air tight

waterproof bag. This limits the oxygen available to what was

there when the bag was sealed, once that's used up there will be

no further oxidation. Also the humidity is constant inside

the bag.

You can get these same benefits simply by sealing things into Zip

Lock plastic bags. It helps if you zip up all but the last

1/4" then compress the bag to get out as much air as possible then

zip up the last bit. This also minimizes the space that the

bag occupies.

Try to place items in storage where temperature cycling is

minimized, but this is not always an option.

Design Defects

In some cases it is sold as a "Feature".

In some cases it kills the product or manufacturer. Long ago

HP came out with a doppler radar module. The idea was to

hook up an antenna, supply DC power and get the audio doppler

signal out. It involved a lot of specialized construction

and tooling. But there was a design defect that greatly

degraded the signal to noise ratio compared to a different

topology. The product disappeared from the market.

LCD Backlight in PRC-126

In other cases is just fixed. The first PRC-126 radios added a back light

to the LCD display and it also was supposed to be night vision

goggle compliant. The designer placed a very dark green

filter above the LCD and this worked great for night vision goggle

use and I'm sure that's where all the effort was focused since

this was a new high tech area, BUT you could not read the LCD in

daylight.

Later radios fixed this by placing the dark green filter between

the back light and the LCD.

The Rolls Royce cars with V-8 engines use an aluminum block and

steel cylinder liners. The aluminum thickness between

cylinders is maybe 1/8" or less. When (not if) the rubber

O-rings sealing the steel liners to the block fail (see Rubber Parts above) the engine overheats causing

irreparable cracks in the thin block wall. The last I heard

Rolls was going to buy engines from BMW. It's too bad that

the company has been going down hill ever since Mr. Royce

died. The cars he designed were built to be reliable.

RR won many races, not by being fast, but by

finishing. That's why Lawrence of Arabia used the PII

chassis as the bases for armored cars. The PII was also

featured in one of the Indiana Jones movies.

Fluke Test Leads

The new style test leads that come with the Fluke model 87 DMM and are made by

Fluke have failed three times. The failure mode is that ALL

the strands of wire fracture in the same plane about 1/8" past the

strain relief behind the shrouded banana plugs at the probe

end. This is not a stress type fracture where you can see

deformation of the metal, but rather as if the wire had been cut

in a shear. This has happened to me with 3 different sets of

test leads. Each time Fluke was notified not only that there

was a failure, but that it was most likely a design or

manufacturing defect that caused it.

One of the symptoms of the failure is that the meter reads zero

volts when in fact there is voltage in the circuit. This is

a safety issue if the meter is being used to determine if a

circuit is hot prior to working on it.

My guess is that there is some type of work hardening stress

(thermal or mechanical) applied to the strands in the

manufacturing process and a small amount of flexing of the wire

causes a fracture.

30 Nov 2006 - It turns out that the test leads were NOT intended

for DMM use. I have purchased DMM test leads and they do

have strain relief on both ends, unlike the above test leads that

did not have strain relief on the probe end. And that's

where they failed.

May 2015 - This time it was Greenlee UL Listed 67KM test leads

that failed. I thought my Fluke 87V DMM was reading very low

on DC current, but it turned out to be bad test leads AGAIN!

Test Leads causing low DC current readings

|

It's not clear why the black banana plug

showed erratic

Ohms readings? It's not severed like the prior lead

failures, but there might be some broken strands.

It's hard to be sure because I cut some strands

when removing the molded part and the insulation.

|

Lap Top Li-Ion Battery

My Sony Vaio PDGA-BPZ52 Lap Top Li-Ion battery has failed.

It's rated at 14.8 volts 4.2 AH. When connected to the lap top

the battery window shows it's model and serial number and says it's

been discharged 31 times and has zero charge and that it's being

charged. But after hours no charge accumulates in the battery.

Inside there are 12 cells each rated at 3.7 volts, so 4 cells in

series would make the 14.8 volts. There seems to be 3 plastic

cell holders each with 4 cells. The cells are all

interconnected with welded tabs. Only 5 tabs are connected to

the PCB so there's no way that each individual cell is being

monitored. The cells are connected in groups of 3 in parallel.

So the left tab is ground, the next tab to the right is 3.7 V (3

cells in parallel), the next tab to the right is 7.4 v (3 parallel +

3 parallel), next tab is 11.1 V and the right hand tab is 14.4 V.

Along the narrow side there's a PCB with over a dozen ICs.

The plastic case can be preyed open without breaking it. Next

step is to unsolder the 5 battery connections from the PCB and check

the cells. When 5.25 volts is applied across any of the groups

of 3 parallel cells no current is drawn. The Li-Ion charging

instructions say not to try and charge under these conditions, so it

looks like the cells are really dead. Now to see if

replacement cells are available.

Precision Time & Frequency

GPS 1 PPS Stability

The GPS system provides the most

precise timing signal for the amateur. A GPS receiver, like

the now obsolete Motorola M12+T (soon to be replaced see the

Synergy web site) will provide a 1 PPS output with jitter under 10

ns and this can be reduced either in hardware or software by

applying the sawtooth correction to each pulse.

But the jitter can be increased by a couple of orders of magnitude

if there is multipath. In my case living in a canyon with

100+ foot trees surrounding the house I have severe

multipath. The fix was to set the GPS receiver elevation

mask to 60 degrees (it was set to maybe 10 or 15 degrees).

This solved that problem.

Installing Coax Connectors

When installing crimp type coax

connectors there are

documents

that tell you how much outer jacket to cut off, how much shield

to cut off and how much insulation to strip off. But

somehow now matter how hard you try the numbers don't seem

to match your connector. But after you have soldered the

center pin in place and you find that you need more or less

distance between the pin and the cable shield it can be changed

by sliding your hand along the cable while holding it firmly,

toward the connector reduces the distance and away from the

connector increases the distance.

Also at the start of the assembly process when the furl is put

on the cable before beginning, also slip a few inches of shrink

tubing that will go over the furl. At the very end of the

assembly push the shrink tube up behind the connector and shrink

it. This provides some strain relief.

Counter Trigger Settings

For about a year (after the above

problem was fixed) my data on Cesium standards showed a change in

frequency, which should not happen with a Cesium standard, but

does happen with crystal and Rubidium standards. This

probably was caused by improper setting of the Time Interval

counter triggering. The correct trigger settings for both 1

PPS inputs and for frequency inputs (1 Mhz, 10 Mhz, etc.) are:

- Trigger level at 1/2 of the voltage swing (need to confirm

using BNC-T and scope) in my case it turned out to the

1.25 volts. For example if the SynPacIII with M12+T is

putting out a TTL (5 volt) pulse and the source and load are

50 Ohms then the pulse height is divided by 2. Setting

the trigger level to 2.4 volts (the normal TTL trigger level)

will be very wrong.

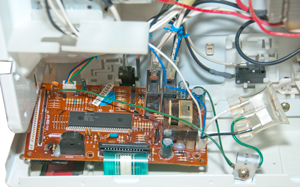

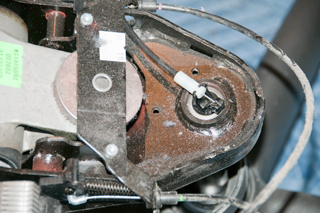

Kitchen Compactor Jam

|

To reduce the volume of recycle items, Al

cans since it's hot now (July 2009) I started to use the

kitchen compactor for the first time in many many

years. It worked a couple of cycles then jammed with

the plunger down. Removing the four screws attaching

it to the counter allowed pulling it out. Then

removing the four top screws gave access to the drive belt,

see photo.

Once jammed there was no response when working the

switch. A probable cause is that the can got pushed to

one side tripping the container safety switch. To

restore operation the belt was worked off the large gear

wheel and while pulling on both sides of the belt the wheel

was turned clockwise (from top see photo) thus manually

raising the plunger. Note the threaded rod was well

down at the jammed position and comes up as the plunger is

raised. If you're not paying attention you'll

get grease on you hand.

It's now working fine. |

Refrigerator Door Shelf Failure

Some time ago there were two

failures of the door shelf where is just fell dumping it's

contents. The problem is very thin plastic where the load is

concentrated.

|

|

|

Brass shim was on good side

of the shelf.

|

This

means that when the refrigerator was cleaned a couple of

weeks ago the brass shim fell out and was replaced on the

wrong side and the shelf was installed in a precarious

way. A slight nudge, like I did yesterday caused the

shelf to fall. This time I've taped the brass shim

so it will not fall out (it was trapped before but no

longer).

|

Refrigerator Light Lens Failure

This is for the Whirpool (Kirkland/Costco) SS25AFXQ00. Parts

drawing No. 34.

WP2254920 Whirlpool Light Lens OEM WP2254920

After two of the four tabs were broken, the plastic was pressed

against the light bulb causing packages on the other side of the

plastic to get transferred onto the plastic.

Need to replace filament bulb with LED bulb that runs much cooler.

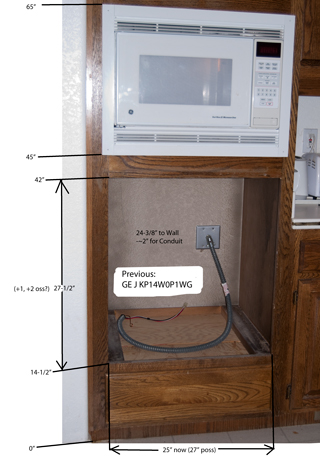

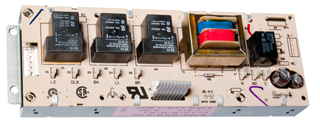

GE Electric Wall Oven Cold (GE JKP14WOP1WG)

When I was baking bread (

Recipes: 5 Minute Bread) the

oven was a little cold, but recently a pie came out with the

bottom dough raw, not cooked at all.

The temperature sensor was replaced during the bread making

attempt to get it working, but had no effect. Gambling on

replacing the controller board does not make sense.

I pulled the oven to measure for a new one to replace the GE model

J KP14W0P1WG that was installed when the house was built in the

late 1990s.

Once out and on the kitchen floor the element resistances could be

easily measured and they both looked OK. The controller

assembly was considered for replacement during the bread baking

investigation but there's a no return policy since it needs to be

special ordered and it was hundreds of dollars.

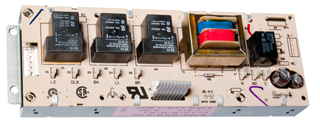

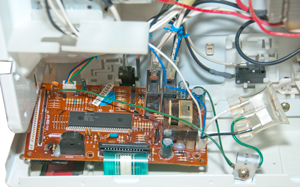

Looking further I could see electrolytic caps on the oven

controller and so thought there's a good change that's the problem

and at that point changed from working on a replacement to seeing

if the old controller could be repaired. The key to the

repair would be using the

ESR-Cap meter

since there's no schematic or repair documentation for the

controler. Just test all the electrolytic caps and see if

any are bad. Two were.

|

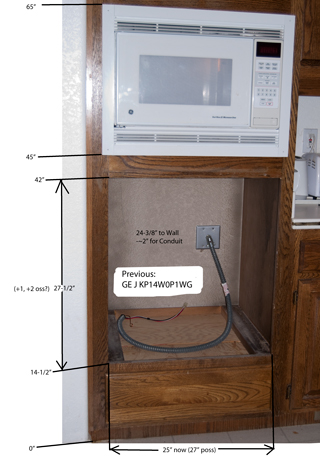

Hole for New Oven

There are dual 15 Amp breakers (240 VAC) now in place for

the old oven.

The new oven requires a dual 20 Amp breaker setup (240

VAC).

Need to find out what size the wires are and if their

ampacity is good for 20 Amps.

If not then repairing the old oven makes more sense.

If the wires are too small to carry the current for the

new oven then there's going to be a real problem.

|

|

Hole for Microwave Oven

There is 3" of space above the top of the cutout until you

get to the bottom of the cabinet.

There is an additional 1" on the left and 1-1/2" on the

right if a bigger hole is needed.

|

|

Separation between Microwave and traditional wall oven.

See photo above, there's a few inches of height from the