FTS 4060 Cesium Frequency Standard

Datum 4065B Time & Frequency Standard

© Brooke Clarke 2004 - 2020 FTS4060/S24

Cesium Frequency Std

Datum 4065B Time & Frequency Standard

Fast Test Method with SR620 Counter

4065B Frequency Offset

Box Rotated

Manual Project

Symmetricom Chip Scale Atomic Clock

Related

Links

Each of the three batteries is has four "X" 5 AH cells where each cell is a Cyclon cylindrical sealed lead acid cell. The 2.5 AH "D" cells were used in the O-1814 Rubidium Time & Frequency standard. The top of each battery is marked "bad" and a date of 10-2-01. The voltage across the pack is now 31.2 VDC but there probably is no current flowing if any one cell is bad, so some testing will be needed to see what the real problem is.

Unlike the FTS 4060 where you manually set the C-Field this one monitors and adjusts based on the following items as reported in the Status 5 menu:

Ramsey Error -10 S.B. <= 160 mv

Rabi-Ramsey Error 0 S.B. <= 40 mv

Zeeman Error -15 S.B. <= 160 mv

Rabi-Zeeman Error -4 S.B. <= 160 mv

Ramsey Confidence +3 S.B. <= 160 mv

7

April 2008

7

April 2008

The Red-Black Siamese cable has male 1/4" Faston connectors that match those on the batteries and so plug into the internal battery wiring connectors. The white label says:

Remote Internal Battery D: -24, E: +24 VDC.

The Plug in the lower right of the photo connects D to black and E to Red. The other end of the cable has female 1/4" Faston connectors to plug into the battery. This solves the two major objections to an internal battery, i.e:

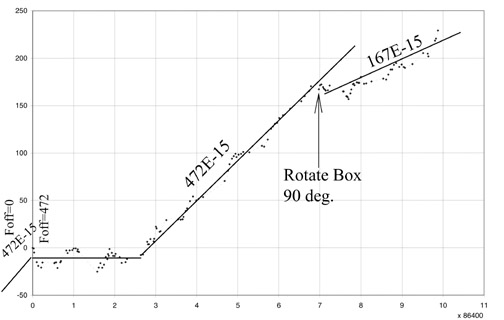

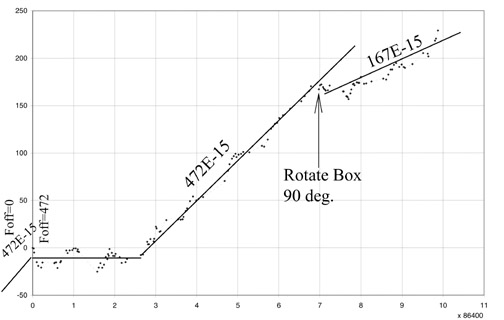

After plotting for the time interval between the 4065B and GPS from 5 May to 7 May (4065plot9.pdf) and finding a straight line with a slope of 472E-15 the Frequency Offset was changed from +000000 to +000472 (a 50-50 gamble that the sign should be +).

A new plot was started 7 May after the change and for the first couple of days seemed to have worked. By starting a new plot I mean that constants were subtracted from the time interval so it starts at 0.0 and the starting second count starts at 0.0. This way is the plot is a straight line it can be forced to go through (0,0).

By May 10 at 9:50 am it looked like the frequency offset had worked. The data (plot10a.pdf)was in a box about +/- 10 ns high after 2 3/4 days (3E-13) but more time needed for good data.

Then the points started a climb. By 14 May (4 days later) the data between May 10 and 14 looks again like a nice straight line (plot10.pdf)with a slope of about 472E-15. BUT the frequency offset is still set at +000472. (4065BvsGPSp10b.pdf). The 4E-13 number floating on the plot is the slope after one day. Just put it there so I could remember what it was. Excel recomputes the slope as each new data point is added.

Before this plot was started the frequency offset was stable at 472 (parts in E-15) and the 4065 Frequency Offset was set to +472.

For the first couple of days it looked like that change was working and the frequency offset was near zero.

But then the frequency offset returned to +472 (this with the Frequency Offset dialed to 472) and that continued for over four days when I turned the 4065 box 90 degrees clockwise (just prior to the day 7 grid line). That made a big change and now (May 17 2008) the slope is more like 167 (parts in E-15).

It may be that the Earth's magnetic field is having an influence or maybe just the mechanical shock has the influence.

Any thoughts what's going on? Contact Brooke

Datum 4065B Time & Frequency Standard

Fast Test Method with SR620 Counter

4065B Frequency Offset

Box Rotated

Manual Project

Symmetricom Chip Scale Atomic Clock

Related

Links

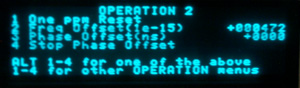

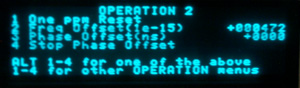

Fast High Precision Set-up of SR 620 Counter

This idea is from the PRS10

Rubidium Frequency standard manual appendix B.

This display should be within 0.1 Hz of 10 MHz

MODE to TIME

SOURCE of Start to A

GATE/ARM to +TIME and EXT

SAMPLE SIZE to 1000 (1 & 103)

Now each second there will be a display of 1,000 averaged readings. This brings the 620 precision down to 1 ps.

Input Connections

- 10 MHz Reference to BNC-T on rear panel 10 MHz Input then to front panel "A" start input

- 10 MHz DUT to front panel "B" stop input

- Front panel 1 kHz TTL REF OUT to front panel EXT Gate input.

Input Setups

- CONFIG - press SET to select cAL and press SELECT to choose "cLoc SourcE", use arrow keys to set rEAr.

- in the Gate field: select POS, TERM = 50 Ohms and LEVEL= +1.0 Volts

- for sine wave 10 MHz inputs set the A and B input

fields to: AC, 50 Ohms, Level full CCW, + Slope.

Coarse Check

MODE to FREQ, SOURCE to B, GATE/ARM to 1 second and SAMPLE SIZE to 1 then hold START down for a few seconds, DISPLAY to MEAN.This display should be within 0.1 Hz of 10 MHz

Fine Frequency Measurement

This will show 1E12 in one second.MODE to TIME

SOURCE of Start to A

GATE/ARM to +TIME and EXT

SAMPLE SIZE to 1000 (1 & 103)

Now each second there will be a display of 1,000 averaged readings. This brings the 620 precision down to 1 ps.

Datum 4065B Cesium Time & Frequency Standard

Background

The FTS4060/S24 is really a frequency standard and I've always wanted an excellent time standard.Condition

This unit came from an eBay ad showing a Major alarm and not locked. But when powered up it locked in about 10 minutes and after connecting the removed and taped battery wire and waiting an additional 10 minutes the charge fault could be cleared.Each of the three batteries is has four "X" 5 AH cells where each cell is a Cyclon cylindrical sealed lead acid cell. The 2.5 AH "D" cells were used in the O-1814 Rubidium Time & Frequency standard. The top of each battery is marked "bad" and a date of 10-2-01. The voltage across the pack is now 31.2 VDC but there probably is no current flowing if any one cell is bad, so some testing will be needed to see what the real problem is.

Theory of Operation

This is a modern Cesium standard that uses control loops so that it's frequency is correct, i.e. the C-field adjustment is automatic not manual like the 4060.Unlike the FTS 4060 where you manually set the C-Field this one monitors and adjusts based on the following items as reported in the Status 5 menu:

Ramsey Error -10 S.B. <= 160 mv

Rabi-Ramsey Error 0 S.B. <= 40 mv

Zeeman Error -15 S.B. <= 160 mv

Rabi-Zeeman Error -4 S.B. <= 160 mv

Ramsey Confidence +3 S.B. <= 160 mv

Power Supply

The AC mains power a 31 VDC supply that's diode ORed with the internal battery and the external DC supply. The internal supply is a 24 Volt lead acid battery, 12 cells of Cyclon "X" size cylindrical sealed pure lead acid. There are a couple of major problems with this:- The temperature inside the case is always warm to almost hot. That degrades the life of the lead acid battery by an order of magnitude.

- If there's any venting, like happened with the Gibbs double oven crystal oscillator, the fumes and heat make a good combination to etch the traces right off printed circuit boards.

7

April 2008

7

April 2008The Red-Black Siamese cable has male 1/4" Faston connectors that match those on the batteries and so plug into the internal battery wiring connectors. The white label says:

Remote Internal Battery D: -24, E: +24 VDC.

The Plug in the lower right of the photo connects D to black and E to Red. The other end of the cable has female 1/4" Faston connectors to plug into the battery. This solves the two major objections to an internal battery, i.e:

- If battery vents acid fumes they will not destroy the expensive circuitry

- The battery will last 3 to 10 times longer when running at room temperature

4065B Frequency Offset

On the FTS4065 the C-Field adjustment is made by the internal microprocessor and there is a seperate Frequency Offset adjustment.After plotting for the time interval between the 4065B and GPS from 5 May to 7 May (4065plot9.pdf) and finding a straight line with a slope of 472E-15 the Frequency Offset was changed from +000000 to +000472 (a 50-50 gamble that the sign should be +).

A new plot was started 7 May after the change and for the first couple of days seemed to have worked. By starting a new plot I mean that constants were subtracted from the time interval so it starts at 0.0 and the starting second count starts at 0.0. This way is the plot is a straight line it can be forced to go through (0,0).

By May 10 at 9:50 am it looked like the frequency offset had worked. The data (plot10a.pdf)was in a box about +/- 10 ns high after 2 3/4 days (3E-13) but more time needed for good data.

Then the points started a climb. By 14 May (4 days later) the data between May 10 and 14 looks again like a nice straight line (plot10.pdf)with a slope of about 472E-15. BUT the frequency offset is still set at +000472. (4065BvsGPSp10b.pdf). The 4E-13 number floating on the plot is the slope after one day. Just put it there so I could remember what it was. Excel recomputes the slope as each new data point is added.

Box Rotated

The 4065 box was rotated 90 degrees and it did make a good sized change.

Before this plot was started the frequency offset was stable at 472 (parts in E-15) and the 4065 Frequency Offset was set to +472.

For the first couple of days it looked like that change was working and the frequency offset was near zero.

But then the frequency offset returned to +472 (this with the Frequency Offset dialed to 472) and that continued for over four days when I turned the 4065 box 90 degrees clockwise (just prior to the day 7 grid line). That made a big change and now (May 17 2008) the slope is more like 167 (parts in E-15).

It may be that the Earth's magnetic field is having an influence or maybe just the mechanical shock has the influence.

Any thoughts what's going on? Contact Brooke

FTS4060/S24

|

|

|

Background

Model Numbers & Options

Operation

Monitor Voltages

Setting C Field

GPS

LORAN-C

Zeeman Resonance

Standby Power

Construction

Patents

5030 Assembly

Manual Control Voltage & Loop Gain Setting

Accessory

Data Request

Government Liquidation Warning

Manual Project

Today, 15 June 2006, thre was a scheduled

power outage whicl PG&E replaced a power pole. Since

I still have not got the Austron 1290 Back Up power supply

operational, I juse connected a couple of 12 Volt 7 AH gel

cell batteries in series with a SB360 Schottky diode.

Using the male plug from a PC hard drive power supply "Y"

cable with the pins reinstalled so that black goes to black

(ground) and red goes to +30 and Yellow goes to orange (+5)

and with the diode cathode to the 4060 + 30 volt line the

batteries held up the 4060 for the 3 hours the mains power was

down. Now I have removed the batteries and a charging

them manually with a bench supply.

Today, 15 June 2006, thre was a scheduled

power outage whicl PG&E replaced a power pole. Since

I still have not got the Austron 1290 Back Up power supply

operational, I juse connected a couple of 12 Volt 7 AH gel

cell batteries in series with a SB360 Schottky diode.

Using the male plug from a PC hard drive power supply "Y"

cable with the pins reinstalled so that black goes to black

(ground) and red goes to +30 and Yellow goes to orange (+5)

and with the diode cathode to the 4060 + 30 volt line the

batteries held up the 4060 for the 3 hours the mains power was

down. Now I have removed the batteries and a charging

them manually with a bench supply.

The 12V 7 AH lead acid batteries are 3.75" from the bottom to the top of the metal terminals. The distance from the bottom of the battery shelf to the bottom of the lid is about 3.75", so it would be a bad idea to try and close the lid with the batteries inside. And there's an even more compelling reason to NOT put lead acid batteries in the same box as electronics. And that's because acid fumes from the lead acid battery will literally eat the traces off the printed circuit boards. So it's best if the batteries are out of the 4060.

It took about 2.7 AH to charge one of the 12 V 7 AH batteries and the power outage was about 2.7 hours, so the FTS4060 is pulling about 1 Amp.

But the 7 AH rating is for a 20 hour discharge (350 ma) so the battery will not last 7 hours at 1 amp. I think the terminal voltage at the end of the power outage was about 23.49 volts or 11.75 volts per battery which is discharged. Maybe 2.7 AH is the capacity at 1 amp?

After AC power is restored the Power On Green and the red Powere Alarm are both on (press the reset button to clear the red alarm LED).

The green lock LED is still on. No battery LEDs are on. (remember the /S24 has no battery option.)

So now I have made up a simple 12 Volt

battery checker that's just a number 1156 car tail light

bulb soldered to a clip lead that was cut in half.

This pulls a couple of amps to light brightly and with only

1 amp will take some seconds to light dimly. This

works much better than the Radio Shack 22-080 battery tester

that shows a dead battery as good.

So now I have made up a simple 12 Volt

battery checker that's just a number 1156 car tail light

bulb soldered to a clip lead that was cut in half.

This pulls a couple of amps to light brightly and with only

1 amp will take some seconds to light dimly. This

works much better than the Radio Shack 22-080 battery tester

that shows a dead battery as good.

Note that the very common 12 V 7 AH batteries come with both 1/4" (0.250") and 3/16" (0.187) quick connect type terminals. On the batteries I got some are 1/4" and some are 3/16". So you need to check each battery, even though at a quick glance they look the same.

Chicago Miniature CMD series LED's.

Red CMD57124A

Yellow CMD 53124A

Green CMD54124A

4499433 Autolock for resonators for frequency standards Feb 12, 1985 Class 331/3; 331/94.1

5714910 Methods and apparatus for digital frequency generation in atomic frequency standards February 3, 1998 331/3; 331/94.1

5656189 Heater controller for atomic frequency standards August 12, 1997 219/499; 219/210; 219/501; 219/505; 330/289; 331/1R; 331/69

5627497 Resonator package for atomic frequency standard May 6, 1997 331/94.1; 331/3

4862101 System for producing spectrally pure optical pumping light August 29, 1989 359/345; 359/886

4588969 Adjustable crystal oscillator with acceleration compensation May 13, 1986 331/156; 331/175; 331/177V

4586006 Crystal oscillator assembly April 29, 1986 331/69; 219/210; 331/70; 331/158

5030 Assembly

Model Numbers & Options

Operation

Monitor Voltages

Setting C Field

GPS

LORAN-C

Zeeman Resonance

Standby Power

Construction

Patents

5030 Assembly

Manual Control Voltage & Loop Gain Setting

Accessory

Data Request

Government Liquidation Warning

Manual Project

Background

A common misconception (and one

that I had until working with a Cesium standard) is that the

timing is perfect. This is not the case. A Cesium

standard wanders around the nominal frequency, but may not

drift like a crystal oscillator. A couple of terms will

help when working with this concept.

Offset - is a measure of how close to the desired frequency an oscillator is running. For example an oscillator that's supposed to be at exactly 10 MHz is off by 0.0001 Hz has an offset of 1E-11. The offset is only valid at the instant when it was measured. It's measure a of how well someone set the frequency not so much about oscillator quality. Since this is something that's under the user's control a lot of time and effort go into minimizing the offset. It's common practice when setting the frequency of a lab grade crystal oscillator to set it right at the edge of the system spec, but on the side where aging will move the frequency so it at first gets better, then it's perfect, then it moves to the other side of the spec. In order to do this the aging rate (i.e. stability) needs to be known.

Note that a Cesium standard may not be set to have a zero offset, but rather most end up with an offset on the order of parts in E13 or E14. The offset is known and can be backed out of measurements on other time standards. But if the Cesium standard will be driving a clock or say a transmitter, the setting the offset to the lowest possible value is important. The key thing is that there is no aging, i.e. a time interval plot vs. GPS will be a straight line whereas a crystal or Rubidium oscillator will have a parabolic plot.

Stability - Stability is the money spec. a measure of how well the frequency stays the same. A perfect oscillator would not change frequency with time, power input, temperature, etc., but you can't get that one. The measure of how the frequency changes with running time is called aging. The specification on the HP (Agilent) 5071A Cesium standard ($50k) is less than 1E-14 per day. . That's to say that if it was set with a zero offset at noon today, by tomorrow noon it might by off frequency by 1E-14.

The plot at the bottom of web page http://www.niceties.com/utcdwh.html (650 days of data) shows what might be a random walk of around plus and minus 100 ns for an HP 5071A.

My s/n 1227 is running at abut -1.4E-14 per day. It would be a tad out of spec for the HP 5071A. Cesium sources are NOT supposed to have aging ike this.

Offset - is a measure of how close to the desired frequency an oscillator is running. For example an oscillator that's supposed to be at exactly 10 MHz is off by 0.0001 Hz has an offset of 1E-11. The offset is only valid at the instant when it was measured. It's measure a of how well someone set the frequency not so much about oscillator quality. Since this is something that's under the user's control a lot of time and effort go into minimizing the offset. It's common practice when setting the frequency of a lab grade crystal oscillator to set it right at the edge of the system spec, but on the side where aging will move the frequency so it at first gets better, then it's perfect, then it moves to the other side of the spec. In order to do this the aging rate (i.e. stability) needs to be known.

Note that a Cesium standard may not be set to have a zero offset, but rather most end up with an offset on the order of parts in E13 or E14. The offset is known and can be backed out of measurements on other time standards. But if the Cesium standard will be driving a clock or say a transmitter, the setting the offset to the lowest possible value is important. The key thing is that there is no aging, i.e. a time interval plot vs. GPS will be a straight line whereas a crystal or Rubidium oscillator will have a parabolic plot.

Stability - Stability is the money spec. a measure of how well the frequency stays the same. A perfect oscillator would not change frequency with time, power input, temperature, etc., but you can't get that one. The measure of how the frequency changes with running time is called aging. The specification on the HP (Agilent) 5071A Cesium standard ($50k) is less than 1E-14 per day. . That's to say that if it was set with a zero offset at noon today, by tomorrow noon it might by off frequency by 1E-14.

The plot at the bottom of web page http://www.niceties.com/utcdwh.html (650 days of data) shows what might be a random walk of around plus and minus 100 ns for an HP 5071A.

My s/n 1227 is running at abut -1.4E-14 per day. It would be a tad out of spec for the HP 5071A. Cesium sources are NOT supposed to have aging ike this.

Cesium standards are a step

better than Rubidium standards and are the basis of the

definition of a second. But that does not mean they are

"perfect".

These are the S24 option that has a 1 MHz front panel output, NSN 6625-01-245-3092. The official definition of a second of time is exactly 9,192,631,770 oscillations of a Cesium atom between the F3 and F4 states.

These were purchased from Government Liquidation with a condition code of "A1" which should mean that they are new. Here are some dates:

These are the S24 option that has a 1 MHz front panel output, NSN 6625-01-245-3092. The official definition of a second of time is exactly 9,192,631,770 oscillations of a Cesium atom between the F3 and F4 states.

First Generation

The HP

5060 was probably the first commercial Cesium

standard. It was all analog, no microcontrollers

then. HP took over the Varian line of Cesium

standards. Then when HP and Agilent split, Agilent

kept the Time and Frequency instruments and HP then became a

computer and imaging company.

Second Generation

The FTS4060 I would call a

second generation Cesium standard because it has a micro

processor that replaces a lot of analog circuitry and is

much easier to use. There is a manual C field

adjustment that needs to be set where the coarse thumb wheel

is 1E-12 per tick and the fine wheel is maybe 1E-14 per

tick.

Third Generation

These standards have a built

in C field setting system that uses the Zeeman effect.

They turn on at a much higher level of accuracy than prior

generations. The Agilent

5071A Primary Frequency Standard ,

Symmetricom 4065C, and others,

These were purchased from Government Liquidation with a condition code of "A1" which should mean that they are new. Here are some dates:

s/n |

First

control voltage date on Lid |

Front

Panel OC-ALC cal date |

| 1013 |

1/27/88 |

1

Mar 02 |

| 1033 |

7/1/88 |

23

Apr 01 |

| 1227 |

3/6/89 |

1

Mar 02 |

Possible meaning: The first

control voltage measurement was done at the factory as part of

the final inspection and so is close to the ship date.

These dates and the serial numbers are in the same

order. The front panel date may be when the units were

tested prior to being put up for auction. These dates

seem to be over 2 years prior to the auction date which may be

due to how fast the government surpluses them. Note that

it's about 14 years from the final test date to the surplus

date. So maybe there is some number of storage years

after which these units are surplused, say 15 years.

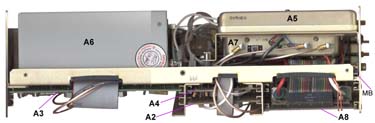

s/n 1013 was shipped outside it's carton and failed to lock when received. Opening the bottom of s/n 1013 shows the Cesium Beam tube, Brick power supply, and fancy 10 MHz crystal oscillator plus other components. Behind the Cs tube is paper work indicating it was replaced in 1996. There must be some reason that s/n 1013 is not working, need a manual to find it. In the left photo at the top of this page notice that the green "LOCK" light is on for the top two standards (1033 & 1227) and off on the bottom (1013) one.

s/n 1013 was shipped outside it's carton and failed to lock when received. Opening the bottom of s/n 1013 shows the Cesium Beam tube, Brick power supply, and fancy 10 MHz crystal oscillator plus other components. Behind the Cs tube is paper work indicating it was replaced in 1996. There must be some reason that s/n 1013 is not working, need a manual to find it. In the left photo at the top of this page notice that the green "LOCK" light is on for the top two standards (1033 & 1227) and off on the bottom (1013) one.

Model Numbers & Options

The normal FTS4060 comes in with

either a 10 MHz optimized output (/201) or a 5 MHz optimized

output (/101).

The /S24 option was a special unit made for the U.S. military and has only a 1 Mhz output on the front and rear panels and does not have other frequencies as outputs and does not have the 1 PPS output. It does not have the internal or external DC supply options. It's a stripped down model.

All of my units (s/n 1013, 1033, 1227 have the SMA-f connector on the A5 Distribution Amplifier Assembly, but not all /S24 units have this connector. It's the 10 MHz output at about 4.4 V Pk-Pk.

My s/n 1013 has a rear panel with a number of plugs like it was the same rear panel used for a full featured 4060, but s/n 1227 has a solid rear panel with no plugs, so in order to install the 10 MHz port I moved the alarm connector to the inside of the box and replaced it with the 10 MHz output.

Note that some FTS 4060 use a 5 MHz OCXO and others use a 10 MHz OCXO.

Option numbers

061 - 1 MHz and 100 kHz RF outputs

116 - Time-of-Day Display and 1 PPS Advance/Delay

117 - 1 PPS Advance/Delay

010 - Internal Battery and Charger

015 - External Standby Battery Supply

013 - Chassis Rack Slides

The /S24 option was a special unit made for the U.S. military and has only a 1 Mhz output on the front and rear panels and does not have other frequencies as outputs and does not have the 1 PPS output. It does not have the internal or external DC supply options. It's a stripped down model.

All of my units (s/n 1013, 1033, 1227 have the SMA-f connector on the A5 Distribution Amplifier Assembly, but not all /S24 units have this connector. It's the 10 MHz output at about 4.4 V Pk-Pk.

My s/n 1013 has a rear panel with a number of plugs like it was the same rear panel used for a full featured 4060, but s/n 1227 has a solid rear panel with no plugs, so in order to install the 10 MHz port I moved the alarm connector to the inside of the box and replaced it with the 10 MHz output.

Note that some FTS 4060 use a 5 MHz OCXO and others use a 10 MHz OCXO.

Option numbers

061 - 1 MHz and 100 kHz RF outputs116 - Time-of-Day Display and 1 PPS Advance/Delay

117 - 1 PPS Advance/Delay

010 - Internal Battery and Charger

015 - External Standby Battery Supply

013 - Chassis Rack Slides

Operation

Just plug in the line cord, set

the Mod switch to ON and the LOOP switch to CLOSED.

After something like 10 minutes to 30 minutes the green LOCK

light will turn on and the ALIGN pushbutton-lamp will turn

off.

You can manually press the Red Operation Alarm Light/Switch to turn it off.

Pressing the AC Power Reset switch will turn off the red Alarm light.

Pressing the Align Light/Switch may turn it off or initiate a new align sequence.

Near the brick power supply on the top side there's a Molex type connector with Red, Black and Orange wires. The connector is the same 4 terminal connector as used for hard drives in PC computers. To get a mating connector buy a "Y" PC power supply cable. You can tease out the male pins using a jeweler's screwdriver if you don't have the extraction tool ( a hollow tube that fits over the male pin). The reassemble with the black wire going to the black ground wire in the FTS4060, Red to the +30 wire and yellow going to the orange +5 volt wire. This makes for an easy way to connect both an external DC backup supply, like the Austron 1290A and also to supply 5 volts for a 1 PPS divider.

It seems that the scale factor for the /S24 using is 1E-13 per count NOT the 2E-14 in the normal FTS4060 manual.

9 Jan 2005 - Plot -

10 Jan 2005 - Plot of nano seconds of Time Interval vs seconds of running time for s/n 1013 - 5.9E-12?

12 Jan 2005 - Plot - Between 124,920 and 169,680 (12.4 hours) the 1 PPS input to the PRS10 was removed and when reconnected caused a negative swing that lasted until 248,400 seconds. But it appears that a C-Field setting of 913 is pretty close to correct. The drift is in the e-13 ot E-14 area.

18 Jan 2005 - Plot of s/n1013 vs. s/n 1227, 1227 vs GPS & 1013 vs GPS, now using s/n 1227 as 10 MHz ref for SR 620 counter.

s/n 1227 has it's C Field set at 600 as received from Govt Liq. and it appears to be moving at -3.6E-12. s/n 1013 seems to be moving at 5E-10 more like an OCXO than a Cesium, but the Lock LED is on and the beam current peaks as it should. What wrong?

1 Feb 2005 - s/n 1227 - I tried to use the time interval between GPS and the 1 Mhz output to set the C Field by getting the offset and then dialing in the correction (it looked like the three thumb wheels were 1E-12, 1E-13 and 1E-14), but the resulting slope after a few days of observation seemed to overshoot. A better way would be to use a binary search where at each attempt you would half the error. I think I have the setting to within a single count on the finest wheel, but it'll take some days to see.

10 Feb 2005 - s.n 1227 - Still have C field at 544. The 10 day plot shows GPS wandering within a 150 ns range so the poorest stability might be 1.7E-13, but an average would be more like parts in E-14.

10 Feb 2005 - Enabled Ionospheric correction in GPS receiver and the delta time jumped up to the 500 ns range, so this may account for the 100 or or ns variation the last 10 days. More time will tell.

11 Feb 2005 - changed GPS to track 4 highest satellites and changed elevation mask to 30 degrees.

28 Feb 2005 - The C field

has been at 570 for about 9 days and on average there

does not appear to be any drift, but it's difficult to tell.

2 March 2005 - To improve the stability of the GPS 1 PPS I increased the elevation mask again, this time from 30 degrees to 50 degrees. It has made a big improvement. The standard deviation after 1,000 seconds worth of 1 PPS averaging is now in the 30 ns area where before it was in the 200 ns area. During 3 days of observation there never was a time when there were no satellites above 50 degrees. Since I'm running the GPS receiver in the timing mode (known antenna position) only one satellite is needed for a timing solution.

8 March 2005 - C filed at 565 - After the problem with the 4060 going crazy after a beam current centering. Needed to cycle power to get good operation.

13 March 2005 - Yesterday the counter got unplugged, but neigher the FTS4060 nor the Austron 2100T were unplugged. Both of these instruments have warning LEDs that would indicate a loss of mains power, but the FTS-4060 output frequency became more unstable after this event. This morning I unplugged the FTS4060 for 10 seconds and restarted it. After that the standard deviation on the time interval improved from over 300 ns to more like 30 ns. Maybe there are some power supply caps that need replacing or more caps need to be added?

Also the amount of averaging on the GPS 1 PPS needs to be increased. At 1,000 averages the best stability that can be seen in one day is about

(3 * 35 ns * 2) / (SQRT(1,000) * 86400) = 7.6E-14, but by going to 5,000 seconds the system improves to 3.4E-14. So starting a new plot.

15 April 2005 - Switched to an SynPaQ/III with Motorola M12+T GPS receiver. This unit has 3 to 4 times less variation than the old 8 channel UT+ GPS receiver. But there appears to be a parabolic change in the plot over the past 5 weeks that I don't understand. The C filed has been at 568 since 20 March 2005.

28 April 2005 - the plot for s/n 1227 vs both GPS and Loran-C still appears to be parabolic, indicating some type of aging which is NOT supposed to occur whith a Cesium source. Aging is about -3E-14 per day.

29 April 2005 - the aging rate seems to be slowing down. It's now -2.2E-14/day.

1 Feb 2006 - s/n 1013 seems to be working after having all the modules taken apart (working on technical manual) and then put back toghther again on 9 Dec 2005. Changing the C-field causes a change that takes about a week to settle down (now C=850) and for the last few days the 1 PPS has stayed within about 1 ns of the Motorola M12+T pulse (maybe 1ns/3 days = 4E-14).

6 Feb 2006 - s/n 1013 is showing drift like s/n1227. The equation for s/n 1013 is:

y = 2.7943x2 - 302.64x + 8969.4 and the quality of fit is

R2 = 0.9088. The x-axis is in days and the y-axis is in ns.

The first deritive of the equation has a first term of 2 * 2.7943 * x ns/day or +5.3E-14 drift rate.

I don't know if this is a measurement problem or a problem with the FTS4060 standards.

9 March 2006 - The apparent parabolic aging was a measurement problem related to setting the time interval counter trigger level improperly (50 Ohm source and load TTL should be at 1.25 Volts, NOT 2.4 volts).

Now s/n 1013 is looking very good. Another problem may have been that the Ultra Stable Oscillator coarse frequency was not set properly. It now has been centered and now looks like +4E-13 offset which I'm trying to adjust to be much better.

28 April 2006 -

When plotting Time Intervals in Excel you can fit a

trendline and also get an R squared quality of fit

number. R^2 should be some number of nines for a good

fit. If it's not then there's something wrong.

17 May 2006 - there are times that last for about a couple of hours whee the SR620 is displaying a standard deviation for a 500 second average as high as a few hundred nano seconds. I still don't know what causes this. Some possible things that might cause it are:

LORAN-C

You can manually press the Red Operation Alarm Light/Switch to turn it off.

Pressing the AC Power Reset switch will turn off the red Alarm light.

Pressing the Align Light/Switch may turn it off or initiate a new align sequence.

Monitor Voltages

The Voltages shown on the meter have been scaled to fit the meter's 0 to 5 volt range and are not the actual voltages in the circuit.| Switch |

Name |

Cold |

Locked |

| 1 |

Qz

Oven |

2 |

3.5 |

| 2 |

Cs

Oven |

2.5 |

1.4 |

| 3 |

Beam |

0.3 |

3.8 |

| 4 |

Control |

5 |

2.8 |

| 5 |

Supply |

2.8 |

2.9 |

| 6 |

Charge |

0 |

0 |

Near the brick power supply on the top side there's a Molex type connector with Red, Black and Orange wires. The connector is the same 4 terminal connector as used for hard drives in PC computers. To get a mating connector buy a "Y" PC power supply cable. You can tease out the male pins using a jeweler's screwdriver if you don't have the extraction tool ( a hollow tube that fits over the male pin). The reassemble with the black wire going to the black ground wire in the FTS4060, Red to the +30 wire and yellow going to the orange +5 volt wire. This makes for an easy way to connect both an external DC backup supply, like the Austron 1290A and also to supply 5 volts for a 1 PPS divider.

Setting C Field

|

23 May 2006

Until about a week

ago I was using the GPS 1 PPS as the start pulse

and the 1 Mhz output from the FTS4060 as the

stop pulse into a Stanford Research SR620 Time

Interval Counter and doing 500 second

averages. There are some problems with

this:

With a 1 MHz stop if the TI is between 0 and 200 or between 800 and 1000 there is a chance of rollover points being in the average and between 0 and 100 or between 900 and 1000 it's almost certain that there will be rollover points in the average. Because of this I'm currently slewing s/n 1003 which was at 980 ns and may have an optimum C-field setting of 908 by setting the C-field at 000 where the slew rate may be in the +20 to +40 ps/sec area so it sill take many hours to get the TI to about 500 ns. Note that the 1

kHz out and the cable between Ref Out and B

in, have an associated time delay so the TI

numbers will not match those with a direct

connection.

|

|

17 May 2006 s/n

1227

By plotting the offset vs. C-field switch setting

it's clear that the slope is -1E-13 per tick.

This is also a great way to see which data points

are not valid. For example the old data point

for C-field setting 492 was +9.8E-13 which is maybe

10 times higher than where it may end up. As

of 22 May 2006 it's -6.24E-14 with R2 of 0.84.

When R2 gets up to one or two nines, then we'll see. |

Note that a Cs frequency

source is just like any other high stability source and

needs to have it's frequency set. The big advantage of

Cs is that once set it will not drift like Rb or

Quartz. Note this is because of the defination of

time, and maybe is not reality.

15 Feb 2005 - The time interval plot was drifting up so an adjustment was made to the C field. It turns out that the adjustment was too large. 24 hours after the adjustment for abut 6 hours the time interval stayed constant within about 10 nano seconds. This indicates that even 24 hours after a C field change the frequency has not stabilized. It really does take two to three days for the unit to stablize after a C-field change.

Note that when the C field is misadjusted as much as possible (1.6E-11) the offset is 10 to 100 times better than the best ovenized lab grade crystal oscillators daily aging rate(1E-9 to 1E-10).

Thumb Wheel Switch Sensitivity

11 Dec 2005 - s/n 1013 after complete disassembly and

reassembly seems to be working, not like in Jan 2005.

With C field thumb wheel switches set for 500 the plot of (start = GPS 1 PPS, stop= FTS4060 1 MHz zero crossing) has a positive slope of about 5.7864 ps/sec and the plot with C field at 900 has a slope of -1.7764 ps/sec. So the thumb-wheel switches may have a scale factor of:

Scale Factor = (7.5628 - (-1.7764)) / (900 - 500) = 0.023348 ps/sec or about 2E-14 per click.

See framed coment above the scale factor for s/n 1227 is -1E-13 per tick.

15 Feb 2005 - The time interval plot was drifting up so an adjustment was made to the C field. It turns out that the adjustment was too large. 24 hours after the adjustment for abut 6 hours the time interval stayed constant within about 10 nano seconds. This indicates that even 24 hours after a C field change the frequency has not stabilized. It really does take two to three days for the unit to stablize after a C-field change.

Slew using C Field

9 March 2006 - When using a time interval counter where the start signal is the 1 PPS output from a GPS timing receiver and the stop signal is from the 1 MHz output of the FRS4060 the counter has a range of 0 to 1,000 nanoseconds. If the time interval rolls over you get a saw tooth type plot. In order to slew the time interval away from 0 or 1,000 you can set the C field as far as possible from the correct setting. For example on s/n1013 the correct setting will be near 855, so setting to 000 causes the frequency to slew at about 1,400 ns per day which is an offset of 1.6E-11 but you can see to get a 500 ns change will take about 8.5 hours. Not as fast as you would like. There may be other ways to slew, but so far this works.Note that when the C field is misadjusted as much as possible (1.6E-11) the offset is 10 to 100 times better than the best ovenized lab grade crystal oscillators daily aging rate(1E-9 to 1E-10).

Thumb Wheel Switch Sensitivity

11 Dec 2005 - s/n 1013 after complete disassembly and

reassembly seems to be working, not like in Jan 2005.With C field thumb wheel switches set for 500 the plot of (start = GPS 1 PPS, stop= FTS4060 1 MHz zero crossing) has a positive slope of about 5.7864 ps/sec and the plot with C field at 900 has a slope of -1.7764 ps/sec. So the thumb-wheel switches may have a scale factor of:

Scale Factor = (7.5628 - (-1.7764)) / (900 - 500) = 0.023348 ps/sec or about 2E-14 per click.

See framed coment above the scale factor for s/n 1227 is -1E-13 per tick.

Test Signal

When making a Time Interval

measurement there are different signals that can be

used. The common ones are a 1 PPS, 1 MHz or 10

MHz. The big advantage of the 1 PPS signal is that

it takes a long time for a 1 second rollover. If the

TI counter is triggered with a 1 PPS pulse (like from the

PSR10 Rb source) and the 1 MHz output from the /S24 Cs

source is used as the stop signal to the SR620 then the

data will have a range of 0 to 1 micro second. (i.e. the

period of the 1 MHz signal). If the Cs source can be

off by as much as 1000 counts where each count is 1E-13

then it might be off by as much as 1E-10. When the 1

MHz output is used as the stop signal then rollover might

occur every 1000 seconds. This means that the TI

needs to be measured a number of times inside each 1000

second period. You can not just measure at times

seperated by 24 hours when the source stability might be

as bad as 1E-10.

If a 1 PPS stop signal was available from the Cs source then there would be no rollover problem since a source with 1E-10 stability will only drift 8.6 micro seconds in 24 hours.

I have a WWV clock and when the 1 PPS from the PRS10 is used to trigger the A counter input the counter trigger LED is flashing at exactly (as seen by eye) that same time as the WWV clock changes seconds. This makes it easy to tell which reading is axactly on the minute for manual recoring into an Excell spreadsheet.

If a 1 PPS stop signal was available from the Cs source then there would be no rollover problem since a source with 1E-10 stability will only drift 8.6 micro seconds in 24 hours.

I have a WWV clock and when the 1 PPS from the PRS10 is used to trigger the A counter input the counter trigger LED is flashing at exactly (as seen by eye) that same time as the WWV clock changes seconds. This makes it easy to tell which reading is axactly on the minute for manual recoring into an Excell spreadsheet.

If the 1 PPS output from a

Motorola M12+T Timing receiver had the sawtooth

corrected so that it was not modulating the 1 PPS

position then the time needed to set a Cs standard would

be reduced by a factor of 10 or more. For example

if instead of an uncertatiny of +/- 50 ns on each pulse

the uncertanity was +/- 1 ns then instead of needing

50,000 seconds (13.8 hours) to see 1E-12 you would only

need 1,000 seconds (16.6 minutes)

WRONG #1- Since the saw tooth error is symetrical it gets removed when averaging is done. On a 500 second average using the GPS 1 PPS as the start and the SR620 1 kHz Reference Out as the stop the standard deviation on the group of 500 is right at 9 nano seconds, but the mean value is independent of the sawtooth error.

WRONG #2 - 50 ns is the saw tooth size for the older 8 channel Motorola timing GPS receivers, but the M12+T only has a 9 ns saw tooth.

WRONG #1- Since the saw tooth error is symetrical it gets removed when averaging is done. On a 500 second average using the GPS 1 PPS as the start and the SR620 1 kHz Reference Out as the stop the standard deviation on the group of 500 is right at 9 nano seconds, but the mean value is independent of the sawtooth error.

WRONG #2 - 50 ns is the saw tooth size for the older 8 channel Motorola timing GPS receivers, but the M12+T only has a 9 ns saw tooth.

Direction of Change

If the time interval has a

positive slope then the period of the FTS4060 is

increasing and so to reduce the period the frequency

should be increased and so the thumb wheel switches

should be moved to a higher number. This is for the case

where start is GPS and stop is the FTS4060.

GPS

One way to adjust the C field 3 digit thumb wheel pot is to use GPS. Although there is some jitter on the GPS 1 PPS signal that amounts to maybe plus and minus 50 ns (Motorola 8 chan), the accuracy over a 24 hour period is on the order of 1E-12. The Motorola M12+T has about 9 ns and so is much better. The GPS receiver should be used directly. Also there a lot of jitter on the 1 MHz FTS4060 output, much better to divide it down to 1 kHz or 1 PPS.It seems that the scale factor for the /S24 using is 1E-13 per count NOT the 2E-14 in the normal FTS4060 manual.

9 Jan 2005 - Plot -

10 Jan 2005 - Plot of nano seconds of Time Interval vs seconds of running time for s/n 1013 - 5.9E-12?

12 Jan 2005 - Plot - Between 124,920 and 169,680 (12.4 hours) the 1 PPS input to the PRS10 was removed and when reconnected caused a negative swing that lasted until 248,400 seconds. But it appears that a C-Field setting of 913 is pretty close to correct. The drift is in the e-13 ot E-14 area.

18 Jan 2005 - Plot of s/n1013 vs. s/n 1227, 1227 vs GPS & 1013 vs GPS, now using s/n 1227 as 10 MHz ref for SR 620 counter.

s/n 1227 has it's C Field set at 600 as received from Govt Liq. and it appears to be moving at -3.6E-12. s/n 1013 seems to be moving at 5E-10 more like an OCXO than a Cesium, but the Lock LED is on and the beam current peaks as it should. What wrong?

1 Feb 2005 - s/n 1227 - I tried to use the time interval between GPS and the 1 Mhz output to set the C Field by getting the offset and then dialing in the correction (it looked like the three thumb wheels were 1E-12, 1E-13 and 1E-14), but the resulting slope after a few days of observation seemed to overshoot. A better way would be to use a binary search where at each attempt you would half the error. I think I have the setting to within a single count on the finest wheel, but it'll take some days to see.

10 Feb 2005 - s.n 1227 - Still have C field at 544. The 10 day plot shows GPS wandering within a 150 ns range so the poorest stability might be 1.7E-13, but an average would be more like parts in E-14.

10 Feb 2005 - Enabled Ionospheric correction in GPS receiver and the delta time jumped up to the 500 ns range, so this may account for the 100 or or ns variation the last 10 days. More time will tell.

11 Feb 2005 - changed GPS to track 4 highest satellites and changed elevation mask to 30 degrees.

Note

It's very important that the GPS receiver is properly setup to get the best timing results.2 March 2005 - To improve the stability of the GPS 1 PPS I increased the elevation mask again, this time from 30 degrees to 50 degrees. It has made a big improvement. The standard deviation after 1,000 seconds worth of 1 PPS averaging is now in the 30 ns area where before it was in the 200 ns area. During 3 days of observation there never was a time when there were no satellites above 50 degrees. Since I'm running the GPS receiver in the timing mode (known antenna position) only one satellite is needed for a timing solution.

8 March 2005 - C filed at 565 - After the problem with the 4060 going crazy after a beam current centering. Needed to cycle power to get good operation.

13 March 2005 - Yesterday the counter got unplugged, but neigher the FTS4060 nor the Austron 2100T were unplugged. Both of these instruments have warning LEDs that would indicate a loss of mains power, but the FTS-4060 output frequency became more unstable after this event. This morning I unplugged the FTS4060 for 10 seconds and restarted it. After that the standard deviation on the time interval improved from over 300 ns to more like 30 ns. Maybe there are some power supply caps that need replacing or more caps need to be added?

Also the amount of averaging on the GPS 1 PPS needs to be increased. At 1,000 averages the best stability that can be seen in one day is about

(3 * 35 ns * 2) / (SQRT(1,000) * 86400) = 7.6E-14, but by going to 5,000 seconds the system improves to 3.4E-14. So starting a new plot.

15 April 2005 - Switched to an SynPaQ/III with Motorola M12+T GPS receiver. This unit has 3 to 4 times less variation than the old 8 channel UT+ GPS receiver. But there appears to be a parabolic change in the plot over the past 5 weeks that I don't understand. The C filed has been at 568 since 20 March 2005.

28 April 2005 - the plot for s/n 1227 vs both GPS and Loran-C still appears to be parabolic, indicating some type of aging which is NOT supposed to occur whith a Cesium source. Aging is about -3E-14 per day.

29 April 2005 - the aging rate seems to be slowing down. It's now -2.2E-14/day.

1 Feb 2006 - s/n 1013 seems to be working after having all the modules taken apart (working on technical manual) and then put back toghther again on 9 Dec 2005. Changing the C-field causes a change that takes about a week to settle down (now C=850) and for the last few days the 1 PPS has stayed within about 1 ns of the Motorola M12+T pulse (maybe 1ns/3 days = 4E-14).

6 Feb 2006 - s/n 1013 is showing drift like s/n1227. The equation for s/n 1013 is:

y = 2.7943x2 - 302.64x + 8969.4 and the quality of fit is

R2 = 0.9088. The x-axis is in days and the y-axis is in ns.

The first deritive of the equation has a first term of 2 * 2.7943 * x ns/day or +5.3E-14 drift rate.

I don't know if this is a measurement problem or a problem with the FTS4060 standards.

9 March 2006 - The apparent parabolic aging was a measurement problem related to setting the time interval counter trigger level improperly (50 Ohm source and load TTL should be at 1.25 Volts, NOT 2.4 volts).

Now s/n 1013 is looking very good. Another problem may have been that the Ultra Stable Oscillator coarse frequency was not set properly. It now has been centered and now looks like +4E-13 offset which I'm trying to adjust to be much better.

28 April 2006 -

| Note: GPS has some noise. For example the Motorola M12T+ has a standard deviation of about 9 ns when 500 Time Inteval readings are averaged (reference is some good oscillator). So you might expect that the noise will peak +3 sigma and -3 sigma from the mean value. This means that the offset you can see is about 54ns/(measurement time in seconds). |

| Meas

time range |

observable offset |

| 1

to 4 min |

1E-9 |

| 15

min to 1 hr |

6E-11 |

| 1

to 4 hr |

1E-11 |

| 12

to 48hr |

1E-12 |

| 1

- 4 days |

6E-13 |

| week

to month |

1E-13 |

17 May 2006 - there are times that last for about a couple of hours whee the SR620 is displaying a standard deviation for a 500 second average as high as a few hundred nano seconds. I still don't know what causes this. Some possible things that might cause it are:

- multipath may cause a problem if there was only one or two sats visable, but I would think with 3 or more visable a poor satellite would not cause a problem?

- no satellites at all would allow the GPS receivers 1 PPS to be coming from it's raw crystal

- some problem with the SR620 - I have disconnected the PRS10 as the external ref since it's not needed and between the PRS10, it's power supply, GPS receiver there's just that much more to go wrong. But this has not seemed t make any difference.

|

Rollover

Instead of connecting the cesium 1 MHz signal to the

B input, connect the 10 MHz signal to the counter's

rear panel 10 Mhz input. Use SEL, SET &

SCALE^V to enable rear clock input. Then

connect the front panel 1 kHz Reference TTL

output to the B (stop) input. Now the rollover

will be every 1 mS, or a thousand times improvement.The problem was

that the data was getting near the 1,000 uS

rollover point caused by using a 1 Mhz signal

for the counter B (stop) input.

SR620 Trick

|

|

Excel Tip

If you're using Julian Day numbers (maybe 6

digits) and have less that 20% of the JDN worth of

data, the Excel trend line will be in error.

Much better to subtract a very large constant from

the JDN so that the x-axis starts from zero.

This way the trend line is correct.The number of data points should be the same on either side of a straight trend line. In my case ALL the data points were on one side of the line. |

LORAN-C

The LORAN-C system will

continue and will be improved (2005) and offers a high

quality time transfer capability.

The Austron 2100F or 2100T will work for this application.

The Austron 2100F or 2100T will work for this application.

Zeeman Resonance

The HP 5060A manual says the

Zeeman frequency should be 42.82 kHz and about 1 volt

RMS. And that an error in the Zeeman signal of 1%

translates into a Cs frequency error of 3.6E-12, so it needs

to be set to within about 1 Hz. The amplitude of the

Zeeman signal and the C-Field can be adjusted, with the

modulation off and the loop open to set the C-Field, or the

C-Field can be measured by adjusting the frequency and

amplitude of the Zeeman input to get maximum beam current.

Mr. Pieter Zeeman won the Nobel prize in Lecture 1902 along with Mr. Lorentz for explaining a splitting in the spectral lines of light caused by magnetic fields. This explanation was based on the new things called "electrons", but did not take into account quantum effects like up and down spins. His experiments and the theory by Lorentz shed a lot of light on what an "electron" was.

So far I don't have an audio generator that has the required frequency settability AND enough drive power to do this test.

Corby D Dawson and Tom Van Baak have described how the audio frequency for the Zeeman effect depends on the physics package and I'm rephrasing it here. The definition of the second is based on a Cesium standard running in a zero magnetic field at sea level with a frequency of

9192.631770 MHz. Real Cesium tubes run with a very small magnetic field and so their frequency is slightly off that for a standard second, but the manufacturer knows how far off and allows for it so that the final 10 MHz or 1 PPS is exactly correct.

Note 1 - The C field coils in both HP and FTS Cesium tubes have the same milli gauss per milli amp constant and so the C field is determined by how the main frame is setup.

Note 2- The synthesizer that generates the frequency that's fed to the multiplier is also in the main frame and has a frequency that matches the strength of the C field.

Note that as long as the C field and synthesizer are matched to each other the system should work properly.

There may be an error reversing the synthesizer frequencies of the HP5061A and HP5061B

Mr. Pieter Zeeman won the Nobel prize in Lecture 1902 along with Mr. Lorentz for explaining a splitting in the spectral lines of light caused by magnetic fields. This explanation was based on the new things called "electrons", but did not take into account quantum effects like up and down spins. His experiments and the theory by Lorentz shed a lot of light on what an "electron" was.

So far I don't have an audio generator that has the required frequency settability AND enough drive power to do this test.

Corby D Dawson and Tom Van Baak have described how the audio frequency for the Zeeman effect depends on the physics package and I'm rephrasing it here. The definition of the second is based on a Cesium standard running in a zero magnetic field at sea level with a frequency of

9192.631770 MHz. Real Cesium tubes run with a very small magnetic field and so their frequency is slightly off that for a standard second, but the manufacturer knows how far off and allows for it so that the final 10 MHz or 1 PPS is exactly correct.

| Tube Model |

C field milli G 1 |

Synth

2 Freq Hz |

Tube Freq Hz |

Zeeman

Hz |

| 5060A |

||||

| 5061A |

61 |

12,631,771.6 | 9192 631 771.6 | 42.82 |

| 5061B |

76 |

12,631,772.5 | 9192 631 772.5 | 53.53 |

| 5062C |

100 |

12,631,774.3 | 9192 631 774.3 | 70.40 |

| FTS4060 |

Note 1 - The C field coils in both HP and FTS Cesium tubes have the same milli gauss per milli amp constant and so the C field is determined by how the main frame is setup.

Note 2- The synthesizer that generates the frequency that's fed to the multiplier is also in the main frame and has a frequency that matches the strength of the C field.

Note that as long as the C field and synthesizer are matched to each other the system should work properly.

There may be an error reversing the synthesizer frequencies of the HP5061A and HP5061B

Standby Power

Today, 15 June 2006, thre was a scheduled

power outage whicl PG&E replaced a power pole. Since

I still have not got the Austron 1290 Back Up power supply

operational, I juse connected a couple of 12 Volt 7 AH gel

cell batteries in series with a SB360 Schottky diode.

Using the male plug from a PC hard drive power supply "Y"

cable with the pins reinstalled so that black goes to black

(ground) and red goes to +30 and Yellow goes to orange (+5)

and with the diode cathode to the 4060 + 30 volt line the

batteries held up the 4060 for the 3 hours the mains power was

down. Now I have removed the batteries and a charging

them manually with a bench supply.

Today, 15 June 2006, thre was a scheduled

power outage whicl PG&E replaced a power pole. Since

I still have not got the Austron 1290 Back Up power supply

operational, I juse connected a couple of 12 Volt 7 AH gel

cell batteries in series with a SB360 Schottky diode.

Using the male plug from a PC hard drive power supply "Y"

cable with the pins reinstalled so that black goes to black

(ground) and red goes to +30 and Yellow goes to orange (+5)

and with the diode cathode to the 4060 + 30 volt line the

batteries held up the 4060 for the 3 hours the mains power was

down. Now I have removed the batteries and a charging

them manually with a bench supply.The 12V 7 AH lead acid batteries are 3.75" from the bottom to the top of the metal terminals. The distance from the bottom of the battery shelf to the bottom of the lid is about 3.75", so it would be a bad idea to try and close the lid with the batteries inside. And there's an even more compelling reason to NOT put lead acid batteries in the same box as electronics. And that's because acid fumes from the lead acid battery will literally eat the traces off the printed circuit boards. So it's best if the batteries are out of the 4060.

It took about 2.7 AH to charge one of the 12 V 7 AH batteries and the power outage was about 2.7 hours, so the FTS4060 is pulling about 1 Amp.

But the 7 AH rating is for a 20 hour discharge (350 ma) so the battery will not last 7 hours at 1 amp. I think the terminal voltage at the end of the power outage was about 23.49 volts or 11.75 volts per battery which is discharged. Maybe 2.7 AH is the capacity at 1 amp?

LEDs

When running from the batteries the Green Lock LED is on and the red AC Power Alarm LED is on as well as the red Battery LED. But monitor position 6 still shows 0 because there is no charging current.After AC power is restored the Power On Green and the red Powere Alarm are both on (press the reset button to clear the red alarm LED).

The green lock LED is still on. No battery LEDs are on. (remember the /S24 has no battery option.)

Dead New Batteries

At first one of the new batteries not only would not put out any voltage, but actually had reverse voltage across it and the 4060 was still running. This means that the switching supply will keep the 4060 going on less than 12 volts (although it may or may not start a cold 4060 on that low a voltage). The "bad" battery looked just like the good batteries when connected to the charging power supply. So now I have made up a simple 12 Volt

battery checker that's just a number 1156 car tail light

bulb soldered to a clip lead that was cut in half.

This pulls a couple of amps to light brightly and with only

1 amp will take some seconds to light dimly. This

works much better than the Radio Shack 22-080 battery tester

that shows a dead battery as good.

So now I have made up a simple 12 Volt

battery checker that's just a number 1156 car tail light

bulb soldered to a clip lead that was cut in half.

This pulls a couple of amps to light brightly and with only

1 amp will take some seconds to light dimly. This

works much better than the Radio Shack 22-080 battery tester

that shows a dead battery as good.Note that the very common 12 V 7 AH batteries come with both 1/4" (0.250") and 3/16" (0.187) quick connect type terminals. On the batteries I got some are 1/4" and some are 3/16". So you need to check each battery, even though at a quick glance they look the same.

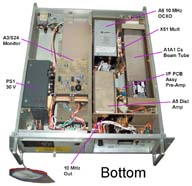

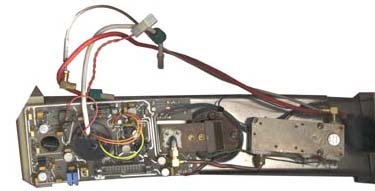

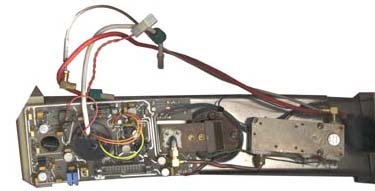

Construction

Top Side

Under the top cover the brick power supply is on the right. Beside it is a tray that could hold rechargeable batteries. There's a 4 position Molex connector with 3 sockets installed on wires that are Red, Black and Orange marked "26" that's probably the battery pack connector. There is a PCB behind the left metered panel and another PCB behind the setup controls located behind the door on the right.Chicago Miniature CMD series LED's.

Red CMD57124A

Yellow CMD 53124A

Green CMD54124A

Patents

The upper left box is marked Model 5030M/201/S25, s/n 199, U.S. Patent 4499433.4499433 Autolock for resonators for frequency standards Feb 12, 1985 Class 331/3; 331/94.1

A system is disclosed for examining the response in atomic and molecular resonators to identify and select the maximum resonant peak and the voltage used to cause said peak to be produced. The system is fabricated of modular elements electrically connected to a circuit board to facilitate its construction and transportation with the resonator. A microprocessor is utilized to perform the analysis and to generate information to select the maximum resonant peak, and the system includes means to compare the value of successively generated resonator outputs and to select the output with the maximum peak.3967115 Atomic beam tube June 29, 1976 250/251; 331/3; 331/94.1 by FTS (3967115.pdf)

Class 331 is Oscillators and /3 is Molecular resonance stabilization

The idea of this invention is to use a microcontroller (RCA or Hughes 1802 CMOS) to sweep the control voltage to the 10 MHz OCXO across it's range and watch the CBT output peaks and valleys. By looking for a peak with aproximate equal valued adajacent valleys on both sides the maximum peak can be selected and that peak used to lock the servo system tying to CBT to the 10 MHz reference. The three DAC1006 Digital to Analog converter chips that are part of the A/D system reading the CBT output voltage is potted in a clear compound probably to reduce elakage currents. J2 is the OCXO control voltage output.

Other FTS Patents

5721514 Digital frequency generation in atomic frequency standards using digital phase shifting February 24, 1998 331/3; 331/94.15714910 Methods and apparatus for digital frequency generation in atomic frequency standards February 3, 1998 331/3; 331/94.1

5656189 Heater controller for atomic frequency standards August 12, 1997 219/499; 219/210; 219/501; 219/505; 330/289; 331/1R; 331/69

5627497 Resonator package for atomic frequency standard May 6, 1997 331/94.1; 331/3

4862101 System for producing spectrally pure optical pumping light August 29, 1989 359/345; 359/886

4588969 Adjustable crystal oscillator with acceleration compensation May 13, 1986 331/156; 331/175; 331/177V

4586006 Crystal oscillator assembly April 29, 1986 331/69; 219/210; 331/70; 331/158

Other Patents

4899117 High accuracy frequency standard and clock system, Vig; John R, Feb 6, 1990, 331/3 ; 331/176; 331/44; 331/47; 368/202; 368/56"Moreover, in rubidium

frequency standards, the available C-field adjustment range

limits the useful life of the unit. For example, in one of

the most popular rubidium frequency standards currently on

the market, the manufacturer provides a C-field adjustment

range equivalent to +1.5.times.10.sup.-9. The aging rate of

the standard is specified as 2.times.10.sup.-10 per year.

Consequently, at the specified aging rate, the limited

C-field adjustment range limits the useful life of this

rubidium frequency standard to 1.5.times.10.sup.-9

/2.times.10.sup.-10 =7.5 years."

5146184 Atomic clock system with improved

servo system, Cutler; Len, Sep 8, 1992, 331/3 ;

331/79 Inside the 4060/S24

J3 is the signal coming from the

I/F PCB of the CBT. J4 is the 450 Hz output to the A7

X18 multiplier.

At the left rear is the

microcontroller PCB.

At the left rear is the

microcontroller PCB.

There is a 40 conductor ribbon cable connection, 2 coax cables and a cable with 2 wires (Red and Black) going to A7 and TP2.

2:50 power on TP2 = 4.97 VDC and the front panel meter on 4 (control voltage) indicates about 5 volts. (2:50 pm)

2:56 Operation Monitor light turned off.

3:00 switching LOOP to Open and back to closed starts meter into sawtooth from 0 to 5 Volts. It takes about 21 seconds to sweep the monitor voltage from 0 to 5 Volts.

But TP2 is sitting at 4.98 VDC so must be a 5 Volt test point or it's some logic indicator that may be pointing to a problem.

21 July 2005 - A3-TP2 a test point to monitor the 450 Hz signal that goes to A7.

To the left of the CBT at the rear is the 10 MHz oscillaotr, marked: Model 1000B. In front of the 10 MHz osc. is The A5 Distrubution Amp metal box with an SMA-f connector just behind the front panel marked J3, RF1 which may be a 10 MHz signal that could be connected to the front or rear panels.

Just

to

the

left

of

the

center

divider is the A3 Alarm PCB with 2 each DB-25 connectors and

no RF coax connections. Marked: D.1652 s/n 865009

(probably 1986 +...) It is not fully populated, missing a few

ICs and a number of discrete parts that probably are part of

the battery charging or monitoring circuit. The 30 VDC

brick power supply is up aginst the left wall.

Just

to

the

left

of

the

center

divider is the A3 Alarm PCB with 2 each DB-25 connectors and

no RF coax connections. Marked: D.1652 s/n 865009

(probably 1986 +...) It is not fully populated, missing a few

ICs and a number of discrete parts that probably are part of

the battery charging or monitoring circuit. The 30 VDC

brick power supply is up aginst the left wall.

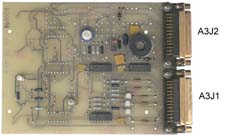

I have named the DB-25m connector nearer the powr supply A3J1 and the DB-25m near the center divider A3J2 since there's no markings on either.

A3J1 pins 23, 22, 24, 25, 2 and 6 are connected to the Monitor thumb wheel switch positions 1 thorough 6 respectively and the switch common goes through the front panel meter to ground.

The Battery Charge, AC Power Alrarm, Battery On andAC Power On LEDs are connected to A3J1 pins 4, 5, 6 and 9 respectively.

Five of the wires on A3J2 are connected to the 5030 Assembly J1 connector.

A3J1 pins 1, 13 and 18 and connected to A3J2 pins 1,2,5,6,8,13 which is probably ground.

At the left rear is the

microcontroller PCB.

At the left rear is the

microcontroller PCB.There is a 40 conductor ribbon cable connection, 2 coax cables and a cable with 2 wires (Red and Black) going to A7 and TP2.

2:50 power on TP2 = 4.97 VDC and the front panel meter on 4 (control voltage) indicates about 5 volts. (2:50 pm)

2:56 Operation Monitor light turned off.

3:00 switching LOOP to Open and back to closed starts meter into sawtooth from 0 to 5 Volts. It takes about 21 seconds to sweep the monitor voltage from 0 to 5 Volts.

But TP2 is sitting at 4.98 VDC so must be a 5 Volt test point or it's some logic indicator that may be pointing to a problem.

21 July 2005 - A3-TP2 a test point to monitor the 450 Hz signal that goes to A7.

Bottom Side

The Cesium Beam Tube is on the right, marked: Cesium Beam Tube, Model FTS-7103, p/n 08923-501, NSN 5960-01-214-7475.To the left of the CBT at the rear is the 10 MHz oscillaotr, marked: Model 1000B. In front of the 10 MHz osc. is The A5 Distrubution Amp metal box with an SMA-f connector just behind the front panel marked J3, RF1 which may be a 10 MHz signal that could be connected to the front or rear panels.

A3 Alarm

Just

to

the

left

of

the

center

divider is the A3 Alarm PCB with 2 each DB-25 connectors and

no RF coax connections. Marked: D.1652 s/n 865009

(probably 1986 +...) It is not fully populated, missing a few

ICs and a number of discrete parts that probably are part of

the battery charging or monitoring circuit. The 30 VDC

brick power supply is up aginst the left wall.

Just

to

the

left

of

the

center

divider is the A3 Alarm PCB with 2 each DB-25 connectors and

no RF coax connections. Marked: D.1652 s/n 865009

(probably 1986 +...) It is not fully populated, missing a few

ICs and a number of discrete parts that probably are part of

the battery charging or monitoring circuit. The 30 VDC

brick power supply is up aginst the left wall.I have named the DB-25m connector nearer the powr supply A3J1 and the DB-25m near the center divider A3J2 since there's no markings on either.

A3J1 pins 23, 22, 24, 25, 2 and 6 are connected to the Monitor thumb wheel switch positions 1 thorough 6 respectively and the switch common goes through the front panel meter to ground.

The Battery Charge, AC Power Alrarm, Battery On andAC Power On LEDs are connected to A3J1 pins 4, 5, 6 and 9 respectively.

Five of the wires on A3J2 are connected to the 5030 Assembly J1 connector.

A3J1 pins 1, 13 and 18 and connected to A3J2 pins 1,2,5,6,8,13 which is probably ground.

5030 Assembly

The Physics package might be

defined as the combination of the Cesium beam tube, the Times

51 Multiplier and the Interface PCB since the latter two items

are bolted to the side of the Cesium Beam Tube.

The Physics Package is in turn a part of the 5030 Assembly. In addition to the Physics Package the 5030 assembly has Most of the parts except the PS1 30 Volt power supply and the A3 Alarm 5 x 6" PCB, and the front and rear panels. The 5030 Assembly is 16 x 7.75 x 5 inches.

To

remove

the

5030

Assembly

remove

the

four 5/32" hex cap bolts, being careful to not let the 5030

assembly crash and move it so that you can easily get to the

SMA connectors and the #2 Philips screws on the "D"

connectors.

To

remove

the

5030

Assembly

remove

the

four 5/32" hex cap bolts, being careful to not let the 5030

assembly crash and move it so that you can easily get to the

SMA connectors and the #2 Philips screws on the "D"

connectors.

Check to see that the 3 Coax cables are marked 4 (Zeeman audio in), 5 (Rear 1 MHz out) and 7(Front 1 MHz out) that mate to J4, J5 and J7, then disconnect these SMA cables.

Remove the two "D" connectors using a #2 Philips screwdriver and lift the 5030 Assembly free of the chassis.

The Physics Package is in turn a part of the 5030 Assembly. In addition to the Physics Package the 5030 assembly has Most of the parts except the PS1 30 Volt power supply and the A3 Alarm 5 x 6" PCB, and the front and rear panels. The 5030 Assembly is 16 x 7.75 x 5 inches.

To

remove

the

5030

Assembly

remove

the

four 5/32" hex cap bolts, being careful to not let the 5030

assembly crash and move it so that you can easily get to the

SMA connectors and the #2 Philips screws on the "D"

connectors.

To

remove

the

5030

Assembly

remove

the

four 5/32" hex cap bolts, being careful to not let the 5030

assembly crash and move it so that you can easily get to the

SMA connectors and the #2 Philips screws on the "D"

connectors.Check to see that the 3 Coax cables are marked 4 (Zeeman audio in), 5 (Rear 1 MHz out) and 7(Front 1 MHz out) that mate to J4, J5 and J7, then disconnect these SMA cables.

Remove the two "D" connectors using a #2 Philips screwdriver and lift the 5030 Assembly free of the chassis.

Note It is an easy job to

replace the 5030 Assembly and that may allow using the

complete 5030 Assembly from a working /S24 unit to bring a

defunct FTS4060 back on line. This can be done in a

few minutes. But I don't know where the additional

modules are located on a full featured 4060. If they

are on the right side ( the 5030 is on the left side) then

it would be very easy. If they are in the way of

removing the 5030 Assembly then it would take longer.

On the upper left is the 10 MHz OCXO.

At the upper right is the A5 Distribution Amplifier.

This amy be an A5/S24 with the front 10 Mhz output

missing.

By first labeling all the coax

cable ends that will be disconnected, then by removing 2

(+) screws and loosening 2 (-) captive screws and

disconnecting some connectors (no soldering needed) the

combined A5 & A7 assembly can easily be removed.

By first labeling all the coax

cable ends that will be disconnected, then by removing 2

(+) screws and loosening 2 (-) captive screws and

disconnecting some connectors (no soldering needed) the

combined A5 & A7 assembly can easily be removed.

A1A5 Distribution Amp

My units have an A5 amplifier that has a open SMA-f

connector facing forward and that connector has a 10 MHz

signal that's about 4.4 Volts Pk-Pk. But other /S24

units have the connector and some internal parts removed

and so don't have the 10 MHz easy to connect.

The cable from the A5 10 Mhz output to the rear panel is about 40" long, SMA(m) on the A5 end and a bulkhead BNC(f) for the rear panel

The

5030

assembly

mother

board

can

be

seen once the A5+A7 sub assembly is removed. All the

components in the 5030 assembly interface to the mother

board. This greatly minimizes the wiring

clutter. There may be a dozen components on the

mother board.

The

5030

assembly

mother

board

can

be

seen once the A5+A7 sub assembly is removed. All the

components in the 5030 assembly interface to the mother

board. This greatly minimizes the wiring

clutter. There may be a dozen components on the

mother board.

Max dimensions are about 12" x 5" although it's "L" shaped.

Here

only the A1A2 motherboard and the A1A9 input filter at

attached to the 5030 frame.

Here

only the A1A2 motherboard and the A1A9 input filter at

attached to the 5030 frame.

The right hand narrow part is just to get the 40 conductor ribbon cable lined up with the A1A3 uP board.

Dataum 1000B Ultra-Stable 10

MHz oscillator (now Symmetricom

1000B). This is a brick about 3x3x7inches with

all the connections on one of the 3x3" ends. Part

number is 05818-119. There's a DB-9 connector with

the following pinout:

Dataum 1000B Ultra-Stable 10

MHz oscillator (now Symmetricom

1000B). This is a brick about 3x3x7inches with

all the connections on one of the 3x3" ends. Part

number is 05818-119. There's a DB-9 connector with

the following pinout:

The oven insulation is my means of a dewar. The initial aging rate might be <1E-10 per day when new, but can get below 1E-12 after running for some time. The phase noise is lower than -134 dB at 10 Hz, -144 dB at 100 Hz and -157 dB at 1 kHz.

The 10 Mhz output is from a right angle SMB connector pointing down. (All the small coax is terminated with 50 Ohm SMB connectors in the FTS4060).

On top of the 1000B (p/n 05818-119) there's a coarse frequency adjust pot.

To remove the USO three 1/4" nuts need to be removed that are below the A3 uP board and the connectors disconnected.

Some data on a hand picked 100B:

A1A7 x18 Mult & Mixer

Just under the A5 Amplifier is the

Times 18 Frequency Multiplier (10 MHz in, 180 MHz out) and

mixer.

Just under the A5 Amplifier is the

Times 18 Frequency Multiplier (10 MHz in, 180 MHz out) and

mixer.

As seen in the photo the connectors are: 10 MHz in, connector with Black, Gnd, and Red wires going to J4 on the A3 Microprocessor board. Cable with Black, Red, Green (ground) & blue wires soldered to feedthroughs going to connector J4 on Cesium Beam Tube motherboard.. 12.6 MHz input & 180 MHz output.

In the

lower right corner is the A8 Power Supply for the Cesium

Beam Tube that includes the two HIGH VOLTAGE outputs.

The bottom of this PCB is visible at the top left front when

the top cover is removed. You might not

want to have your hands anywhere near this board when power

is applied.

In the

lower right corner is the A8 Power Supply for the Cesium

Beam Tube that includes the two HIGH VOLTAGE outputs.

The bottom of this PCB is visible at the top left front when

the top cover is removed. You might not

want to have your hands anywhere near this board when power

is applied.

Although

this

PCB

is

in

a

slot

and should be able to slide out, it's trapped by the female

thread fitting used to attach the 5030 sub assembly to the

chassis. It has a dual electrolytic cap, a single

electrolytic cap, a diode and an inductor.

Although

this

PCB

is

in

a

slot

and should be able to slide out, it's trapped by the female

thread fitting used to attach the 5030 sub assembly to the

chassis. It has a dual electrolytic cap, a single

electrolytic cap, a diode and an inductor.

At the

bottom center is the 3 x 7" A2/S24 RF Assembly

(56219-05280-011 Assy 05281) that takes in 10 MHz and

outputs 1 MHz. On a full featured 4060 this board

would also output 100 kHz and 10 MHz.

At the

bottom center is the 3 x 7" A2/S24 RF Assembly

(56219-05280-011 Assy 05281) that takes in 10 MHz and

outputs 1 MHz. On a full featured 4060 this board

would also output 100 kHz and 10 MHz.

It may that the 74LS90 divide by 10 circuit could be bypassed to allow two 10 MHz outputs instead of the two 1 MHz outputs that are on the /S24 versions.

The A3

board has a coax input (J2) that takes in the error signal